Impact resisting powder coating for aluminum product

A powder coating and impact-resistant technology, applied in the field of impact-resistant powder, can solve problems such as insufficient coating adhesion, uneven coating thickness, and poor impact resistance, and achieve strong coating adhesion, high impact resistance, and comprehensive good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

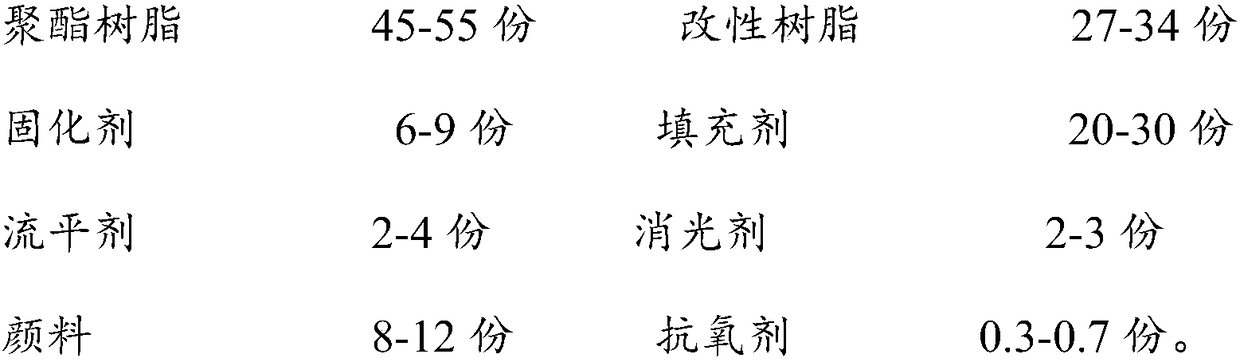

[0024] Impact-resistant powder coatings for aluminum products, the raw material components in parts by mass include:

[0025]

[0026] Its preparation method is:

[0027] 1. Weigh the amount of polyester resin, modified epoxy resin, triglycidyl isocyanurate, asbestos powder, 3777 leveling agent, matting agent SG318, pigment and antioxidant 1010 components;

[0028] 2. Put the polyester resin and modified epoxy resin in a dryer, the drying temperature is 80°C, and the drying time is 10 minutes;

[0029] 3. Put the dried polyester resin, modified epoxy resin, triglycidyl isocyanurate, asbestos powder, 3777 leveling agent, matting agent SG318, pigment and antioxidant 1010 in the mixer , the speed of the mixer is 50rpm, and the mixing time is 3min to obtain the mixture a;

[0030] 4. Add the mixture into the extruder, control the rotation speed of the extruder screw to 200rpm, and the temperature in the extruder cavity to 110°C, and melt and extrude to obtain the compound b; ...

Embodiment 2

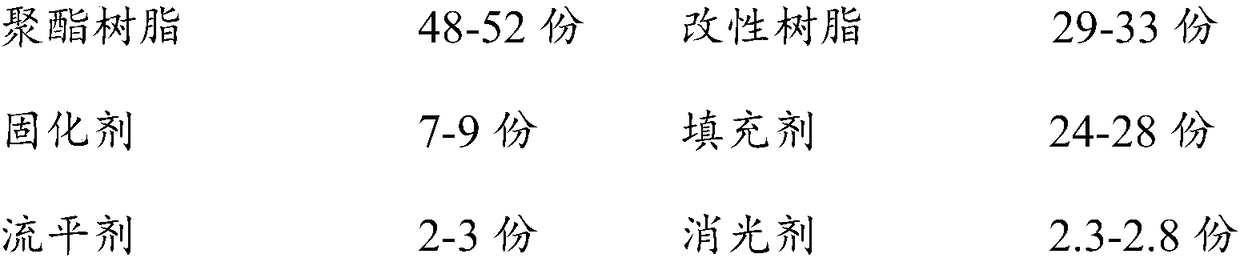

[0034] Impact-resistant powder coatings for aluminum products, the raw material components in parts by mass include:

[0035]

[0036] Its preparation method is:

[0037] 1. Weigh the amount of polyester resin, modified silane resin, triglycidyl isocyanurate, titanium dioxide, FS4400 leveling agent, matting agent SJ-580, pigment and antioxidant 168 components;

[0038] 2. Put the polyester resin and modified silane resin in a dryer, the drying temperature is 64°C, and the drying time is 11 minutes;

[0039] 3. Put the dried polyester resin, modified silane resin, triglycidyl isocyanurate, titanium dioxide, FS4400 leveling agent, matting agent SJ‐580, pigments and antioxidant 168 in the mixer In the process, the speed of the mixer is 34rpm, and the mixing time is 7min to obtain the mixture a;

[0040] 4. Add the mixture into the extruder, control the rotation speed of the screw of the extruder to 220rpm, and the temperature in the cavity of the extruder to 117°C, and melt ...

Embodiment 3

[0044] Impact-resistant powder coatings for aluminum products, the raw material components in parts by mass include:

[0045]

[0046] Its preparation method is:

[0047] 1. Weigh the amount of polyester resin, modified phenolic resin, triglycidyl isocyanurate, titanium dioxide and barium sulfate, FS4400 leveling agent, matting agent SG318, pigment and antioxidant 264 components;

[0048] 2. Put the polyester resin and modified phenolic resin in a dryer at a drying temperature of 60°C and a drying time of 15 minutes;

[0049] 3. Mix the dried polyester resin, modified phenolic resin, triglycidyl isocyanurate, titanium dioxide and barium sulfate, FS4400 leveling agent, matting agent SG318, pigment and antioxidant 264 In the machine, the mixer speed is 30rpm, and the mixing time is 8min to obtain the mixture a;

[0050] 4. Add the mixture into the extruder, control the rotation speed of the extruder screw to 300rpm, and the temperature in the extruder cavity to 120°C, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com