In-situ combustion shaft-combustion-preventing fire-extinguishing tail pipe and application thereof

A technology for burning oil layers and oil pipes, which is applied in fire prevention equipment, fire rescue, wellbore/well components, etc., can solve the problems of undiscovered oil layer fire prevention and fire extinguishing technology in wellbore, and achieve simple design, good fire extinguishing effect, and timely disposal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

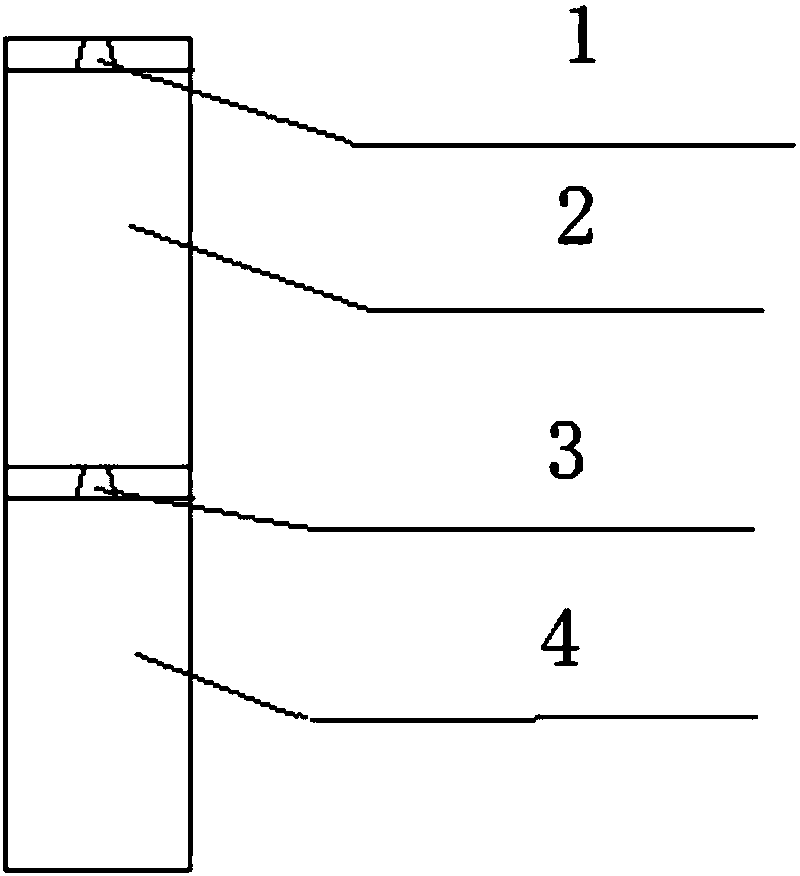

[0025] See figure 1 , is a structural schematic diagram of the wellbore combustion prevention fire extinguishing tailpipe of the present invention. As shown in the figure, the fire extinguishing tailpipe of the present invention includes a first oil pipe (oil pipe A) 2 and a second oil pipe (oil pipe B) 4 connected in series up and down; wherein, the top of the first oil pipe 2 is an upper sealing material (sealing anti-pressure valve ) 1, the bottom end of the first oil pipe 2 and the top end of the second oil pipe 4 are sealed and connected by an intermediate sealing material 3, and the bottom end of the second oil pipe 4 is the sealing end of the oil pipe; and, ABC dry powder fire extinguishing agent is filled in the first oil pipe 2 ( Such as sodium bicarbonate dry powder, modified sodium salt dry powder, potassium salt dry powder, ammonium dihydrogen phosphate dry powder, diammonium hydrogen phosphate dry powder, phosphoric acid dry powder and amino dry powder for fire ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com