Electric arc additive forming method for aluminum alloy structural member

A technology of additive forming and structural parts, which is applied in arc welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problem of the compactness of the forming structure, the difficulty in guaranteeing the stability of the forming process, the unevenness of the forming surface, and the inability to effectively form, etc. problems, to achieve the effect of improving the geometric shape forming ability, good internal quality and stable forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

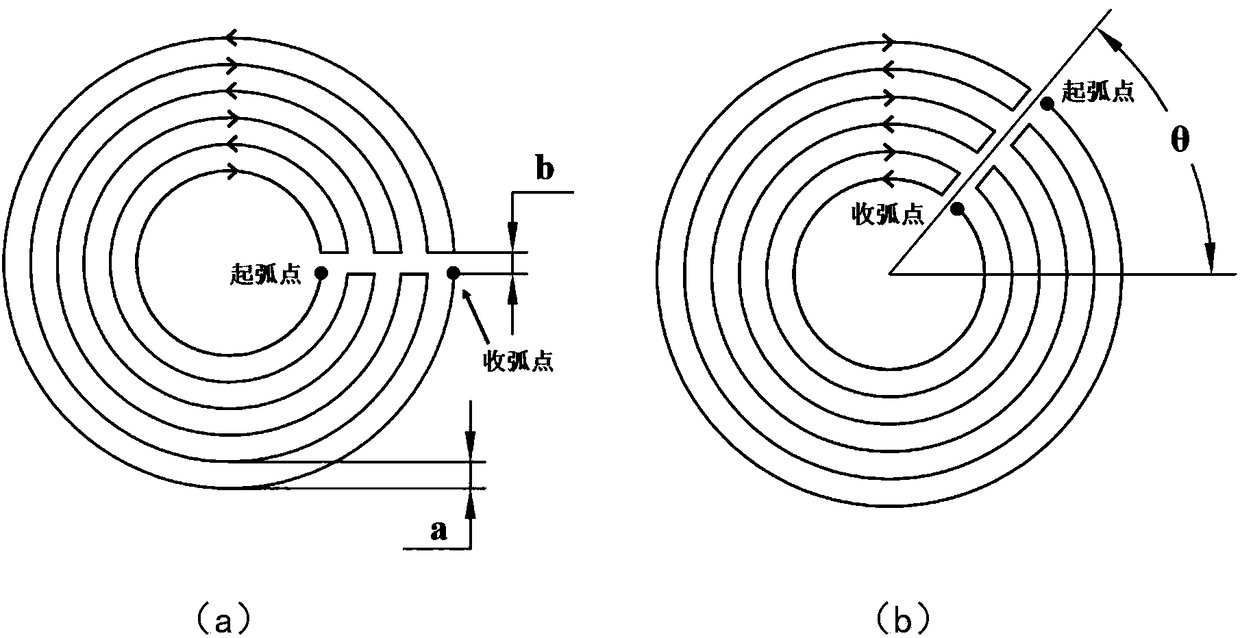

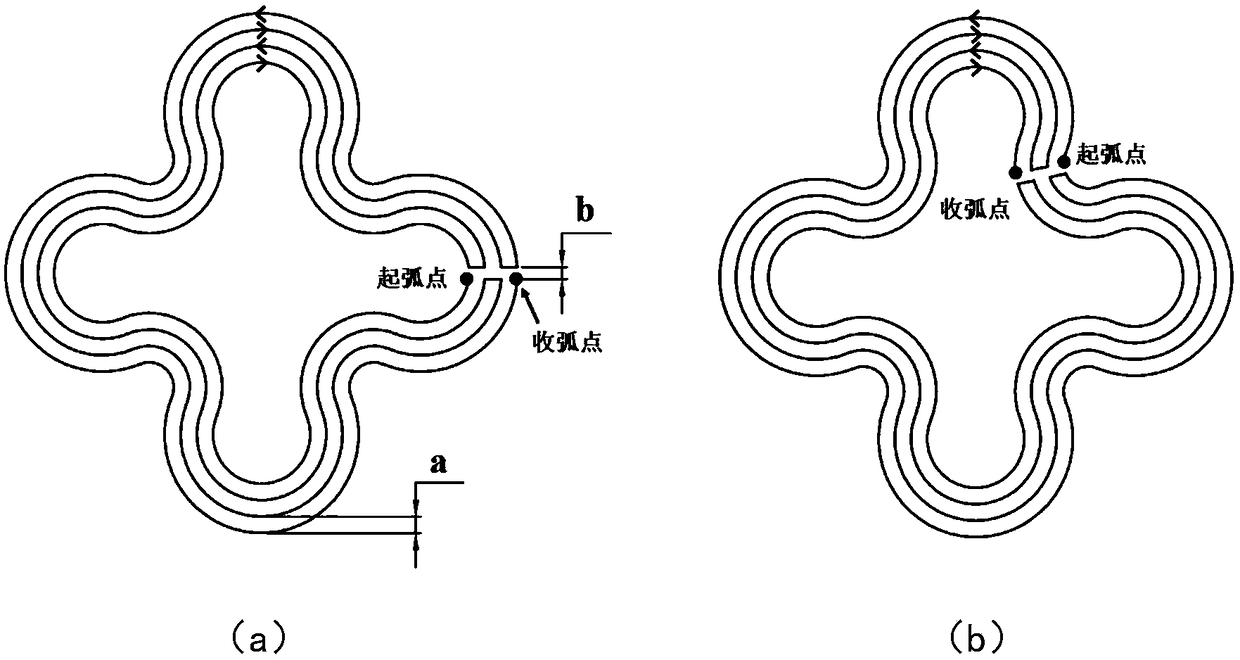

[0025] A method for forming an aluminum alloy structural part by arc additive material, the method comprises the following steps by welding several layers of aluminum alloy materials on the aluminum alloy formed part: (1) setting the working current, wire feeding speed, weld seam width, and welding wire diameter The preset value, wherein, the current is 80-200A, the wire feeding speed is 4-10mm / s, the welding diameter is 0.8-2mm, and the weld seam width is 3-10mm; (2) The welding torch executes the n+th 1-layer welding, wherein n+1 layer welding includes r weld passes, and the welding path directions of adjacent weld passes are opposite; (3) completing n+2th layer we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com