Extrusion molding mould and molding method of large-length-width-ratio aluminum alloy rectangular box-shaped piece

A technology for extrusion forming and box-shaped parts, which is applied in the direction of metal extrusion dies, etc., can solve problems such as the phenomenon of lugs at the end of box-shaped parts, the increase in the allowable deep-drawing deformation, and the difficulty in controlling the defects of the lugs, and achieve improvement. Lug defects, low unit cost, and the effect of improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

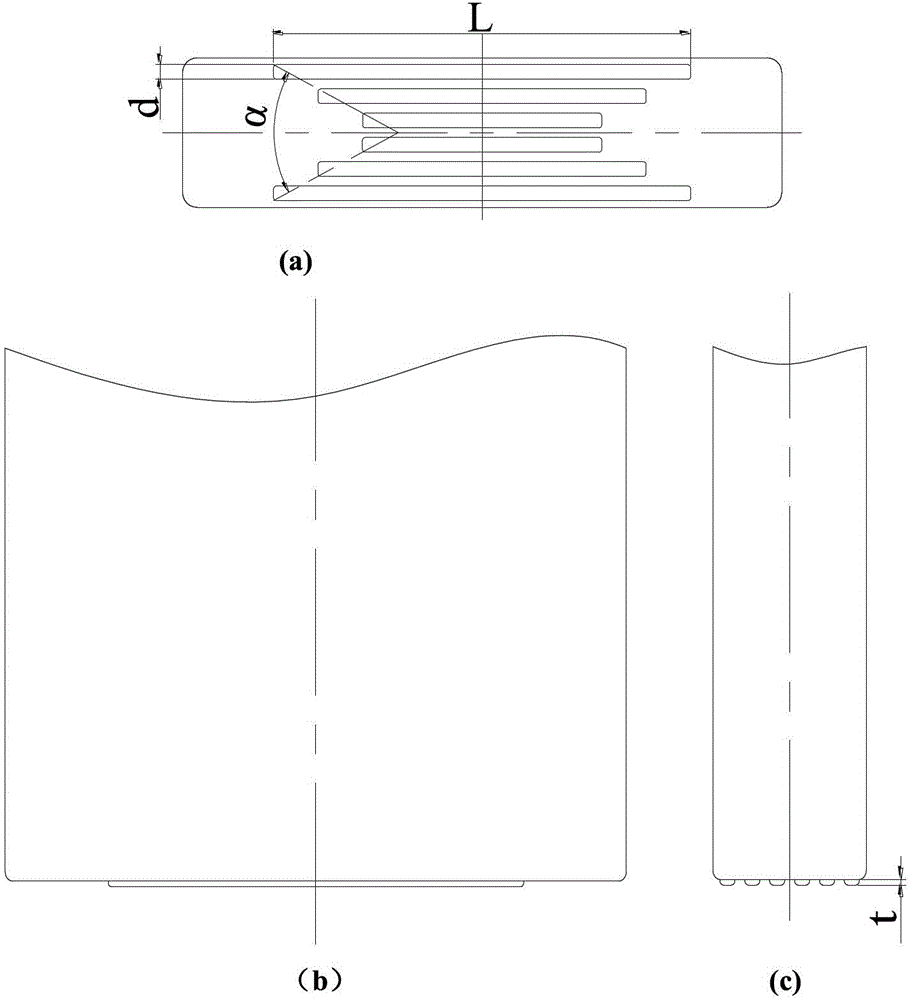

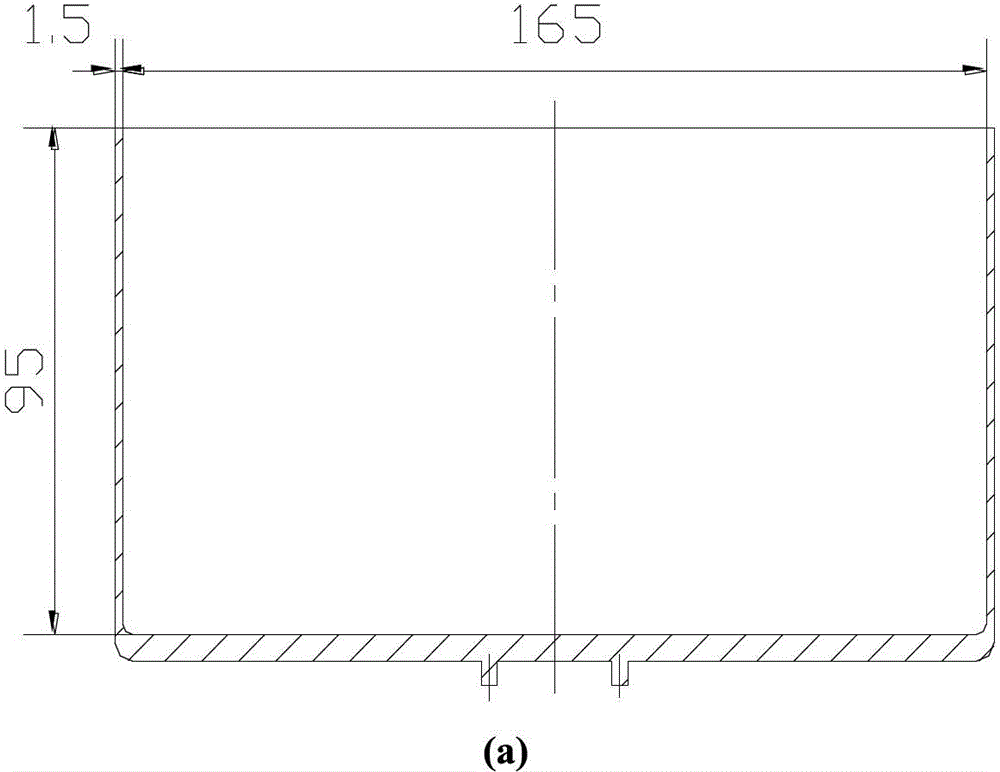

[0030] The first step is to use the annealed 1060 aluminum alloy aluminum material for rough preparation, according to figure 2 The part diagram of the rectangular box-shaped part (with convex column) that needs to be formed is shown, and the size of the rectangular blank is determined as: 167.9mm×43.9mm×13.9mm;

[0031] The second step is to corrode the blank with 10%wt. NaOH solution for 10 minutes;

[0032] The third step is to evenly coat zinc stearate powder on the corroded blank to provide lubrication for subsequent extrusion;

[0033] The fourth step, use such as figure 1 The shown punch with damping ribs is used to extrude rectangular box-shaped parts at an extrusion speed of 10 mm / s. There are 6 damping ribs distributed symmetrically and equidistantly at the bottom of the punch. The specific parameters are: the length of the longest damping rib L=90.0mm, the angle α=60°, the width d=3.7mm, and the thickness t=1.0mm.

[0034] The fifth step, according to the height...

Embodiment 2

[0037] The first step is to use the annealed 1060 aluminum alloy aluminum material for rough preparation, according to figure 2 The part diagram of the rectangular box-shaped part (with convex column) that needs to be formed is shown, and the size of the rectangular blank is determined as: 167.9mm×43.9mm×14.7mm

[0038] The second step is to corrode the blank with 10%wt. NaOH solution for 10 minutes;

[0039] The third step is to evenly coat zinc stearate powder on the corroded blank to provide lubrication for subsequent extrusion;

[0040] The fourth step, use such as figure 1 The shown punch with damping ribs is used to extrude rectangular box-shaped parts at an extrusion speed of 10mm / s. There are 6 damping ribs distributed symmetrically and equidistantly at the bottom of the punch. The specific parameters are: the length of the longest damping rib L=110.0mm, the angle α=100°, the width d=2.2mm, and the thickness t=0.8mm.

[0041] The fifth step, according to the height...

Embodiment 3

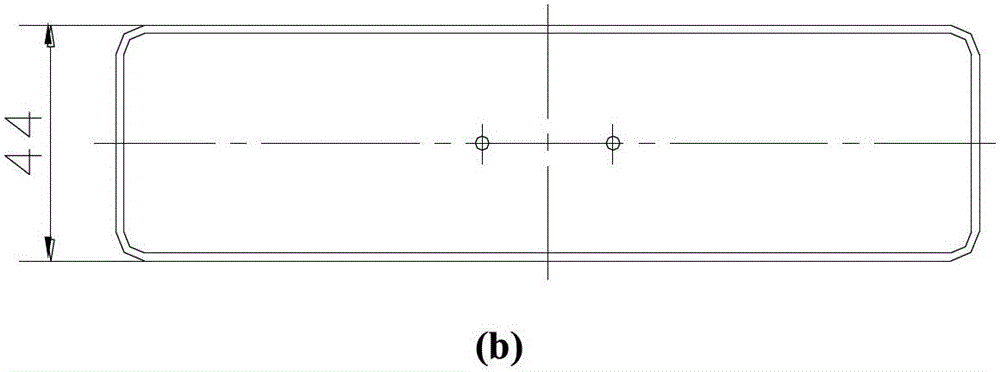

[0044] The first step is to use the annealed 1060 aluminum alloy aluminum material for rough preparation, according to image 3 The part diagram of the rectangular box-shaped part (without convex column) shown in the figure, the size of the rectangular blank is determined as: 167.9mm×43.9mm×14.0mm;

[0045] The second step is to corrode the blank with 10%wt. NaOH solution for 10 minutes;

[0046] The third step is to evenly coat zinc stearate powder on the corroded blank to provide lubrication for subsequent extrusion;

[0047] The fourth step, use such as figure 1 The shown punch with damping ribs is used to extrude rectangular box-shaped parts at an extrusion speed of 10mm / s. There are 6 damping ribs distributed symmetrically and equidistantly at the bottom of the punch. The specific parameters are: the length of the longest damping rib L=90.0mm, the angle α=60°, the width d=3.7mm, and the thickness t=1.0mm.

[0048] The fifth step, according to the height of the box-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com