High-entropy flux-cored wire used for aluminum-steel submerged arc welding and preparation method thereof

A technology of flux-cored welding wire and submerged arc welding, which is applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of reduced strength of welded joints, and achieve the effects of improved compatibility, excellent strength and toughness, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below.

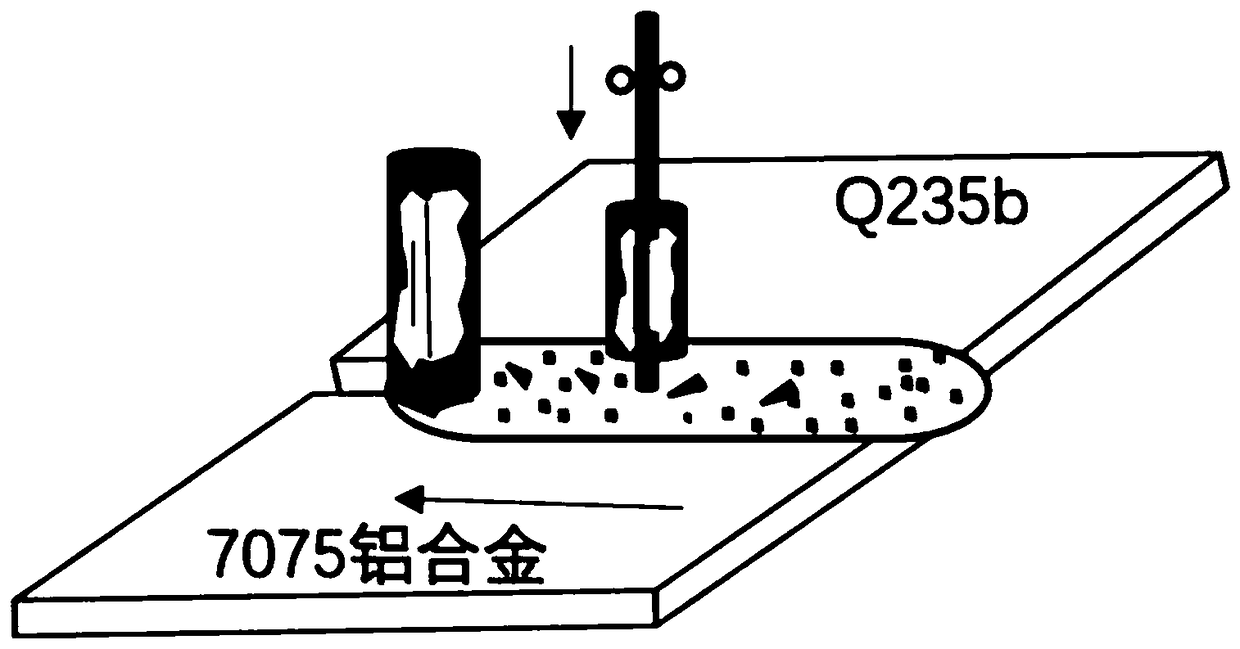

[0024] A high-entropy flux-cored wire for aluminum-steel submerged arc welding, including a powder and a sheath.

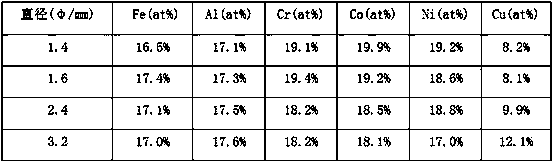

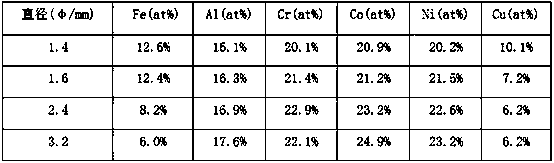

[0025] The powder is prepared according to the atomic percentage of the following components, the total atomic percentage is 100%, of which Fe 5~15%, Al10%~19%, Co 18%~25%, Cr 20%~35%, Ni 20%~35% %, Cu 5%~13%;

[0026] The sheath material is industrial high-purity copper strip (99.99%) with a width of 10±0.1mm and a thickness of 0.5±0.03mm.

[0027] The preparation method of the above-mentioned high-entropy flux-cored welding wire is implemented according to the following steps:

[0028] Step 1. Melting master alloy

[0029] Composition by atomic percentage (see Table 1), the total atomic percentage is 100%, convert the atomic percentage into mass percentage, weigh various high-purity metals (99.99%) according to the mass percentage; mix the above metal materials in a ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com