External thread core pulling mold of injection molded protective cover and mold core thread machining method

An external thread and protective cover technology, applied in the field of plastic molds, can solve the problems of difficulty in ensuring the maximum outer circle coaxiality of products, ununiform starting positions of threads, and limitations of mold water transport design, etc., to save mold space, internal Effects of stress reduction and dimensional stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

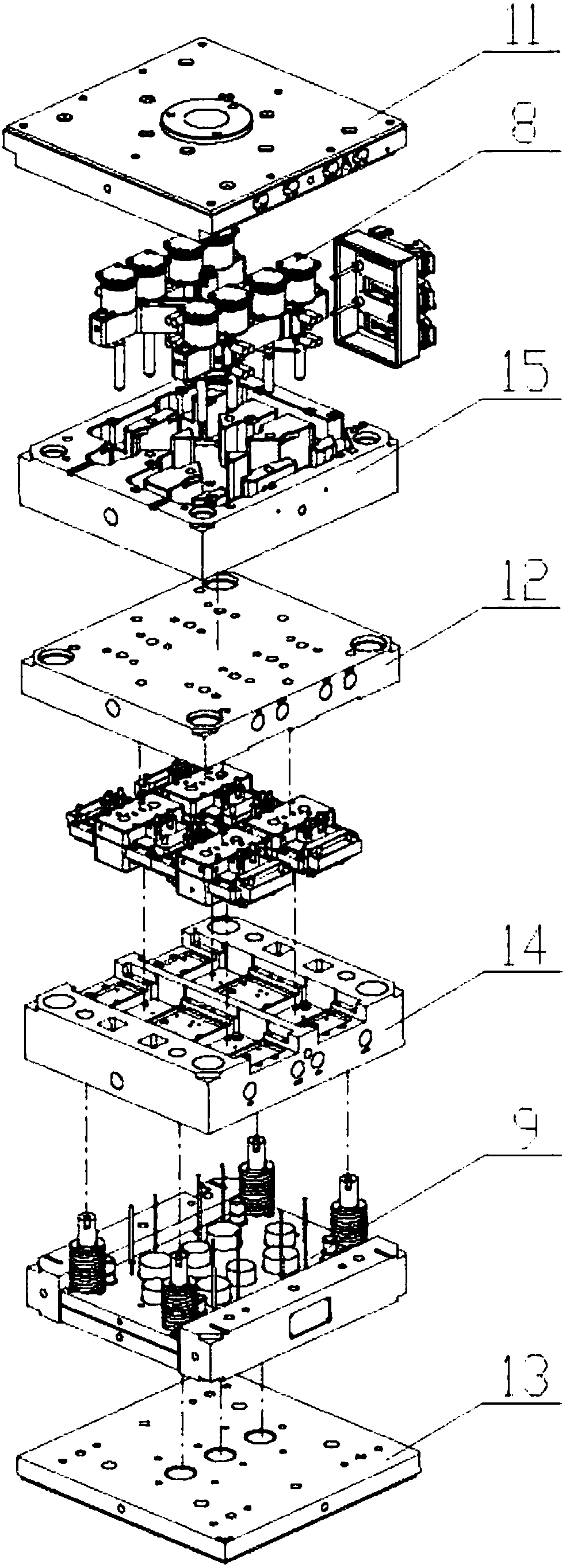

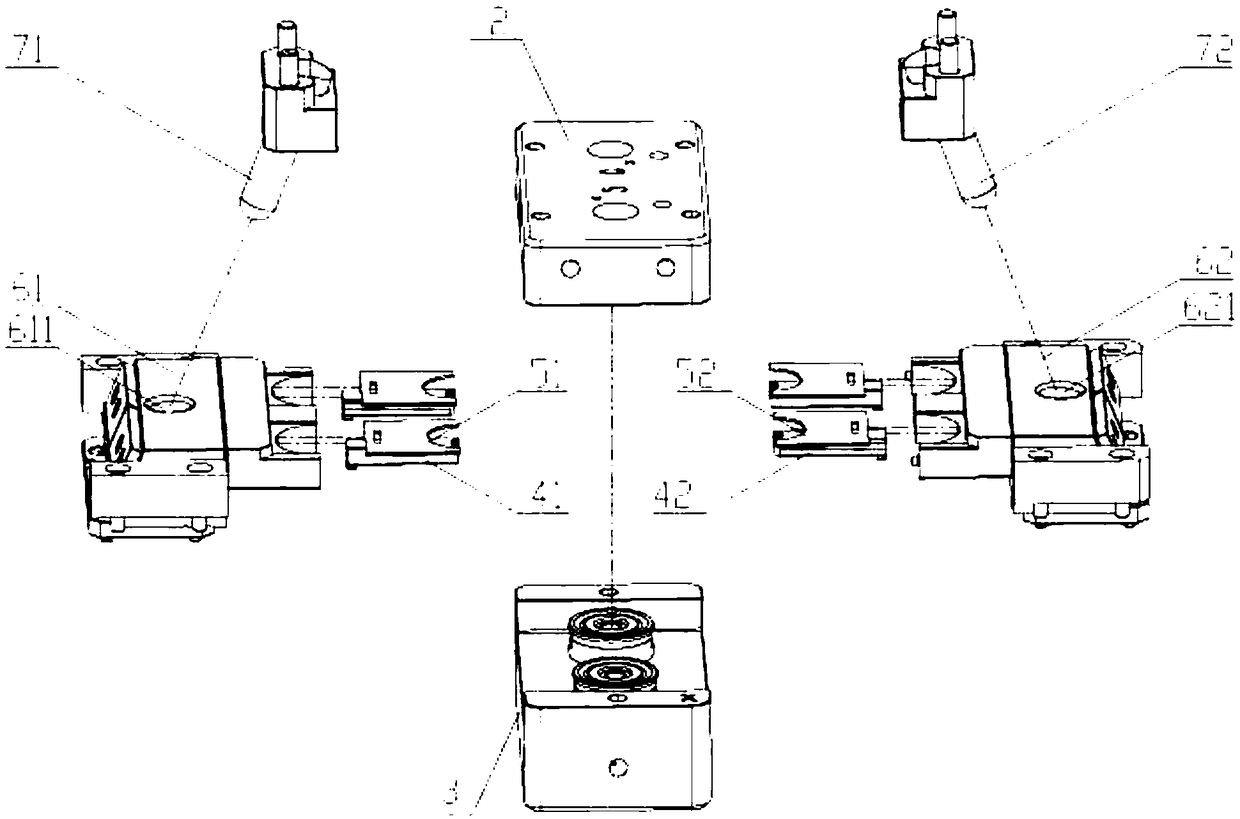

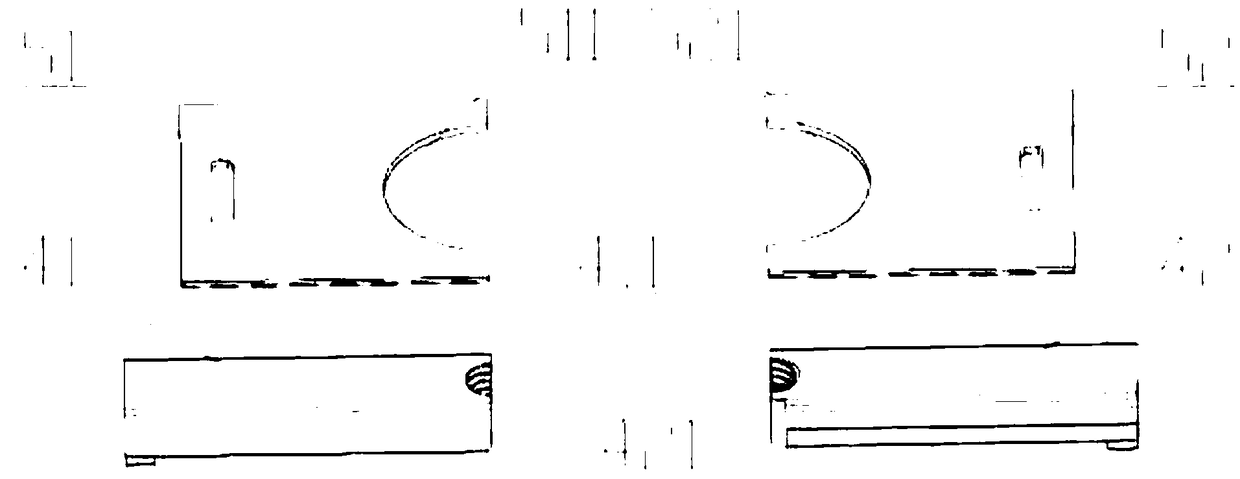

[0022] figure 1 It is an explosion schematic diagram of an external thread core-pulling mold for an injection protective cover proposed by the present invention, figure 2 It is an exploded schematic diagram of the inner mold and side core-pulling mechanism of an external thread core-pulling mold for an injection protective cover proposed by the present invention, image 3 It is a schematic diagram of a mold core of an external thread core-pulling mold for an injection protective cover proposed by the present invention.

[0023] refer to Figure 1-3 , a core-pulling mold for an external thread of an injection protective cover proposed by the present invention, comprising: a fixed mold assembly, a movable mold assembly, an inner mold, a mold core, and a side core-pulling mechanism;

[0024] The fixed mold assembly includes a panel 11, a front template 12 and a heat shield; the heat shield of the front template 12 is respectively installed on both sides of the panel 11, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com