A green and efficient synthesis method of aryl acrylonitrile compounds

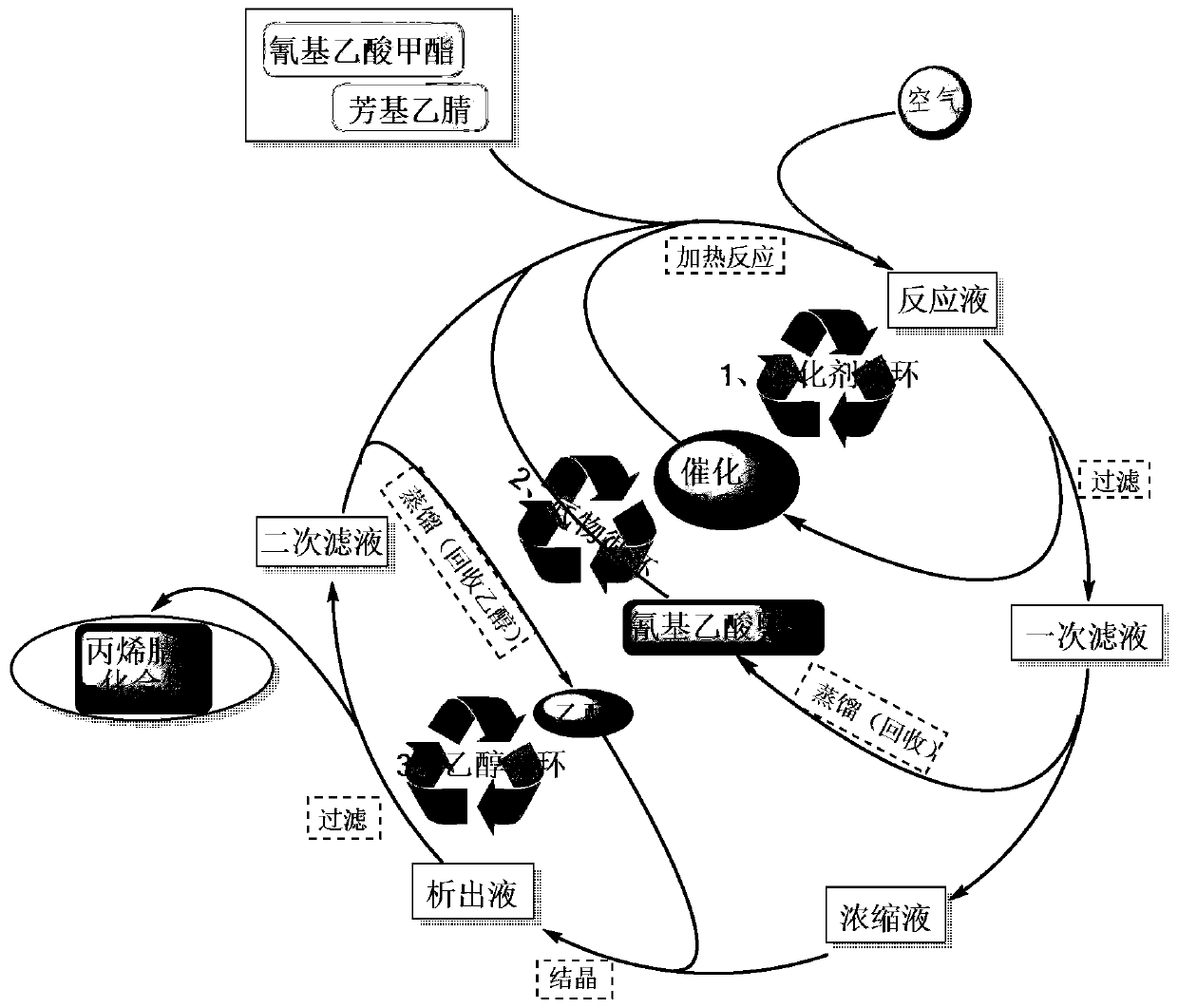

A technology of arylacrylonitrile and synthesis method, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry and other directions, can solve problems such as pollution of the environment and a large amount of alkaline waste water, achieve good purity, reduce production costs, and reduce The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

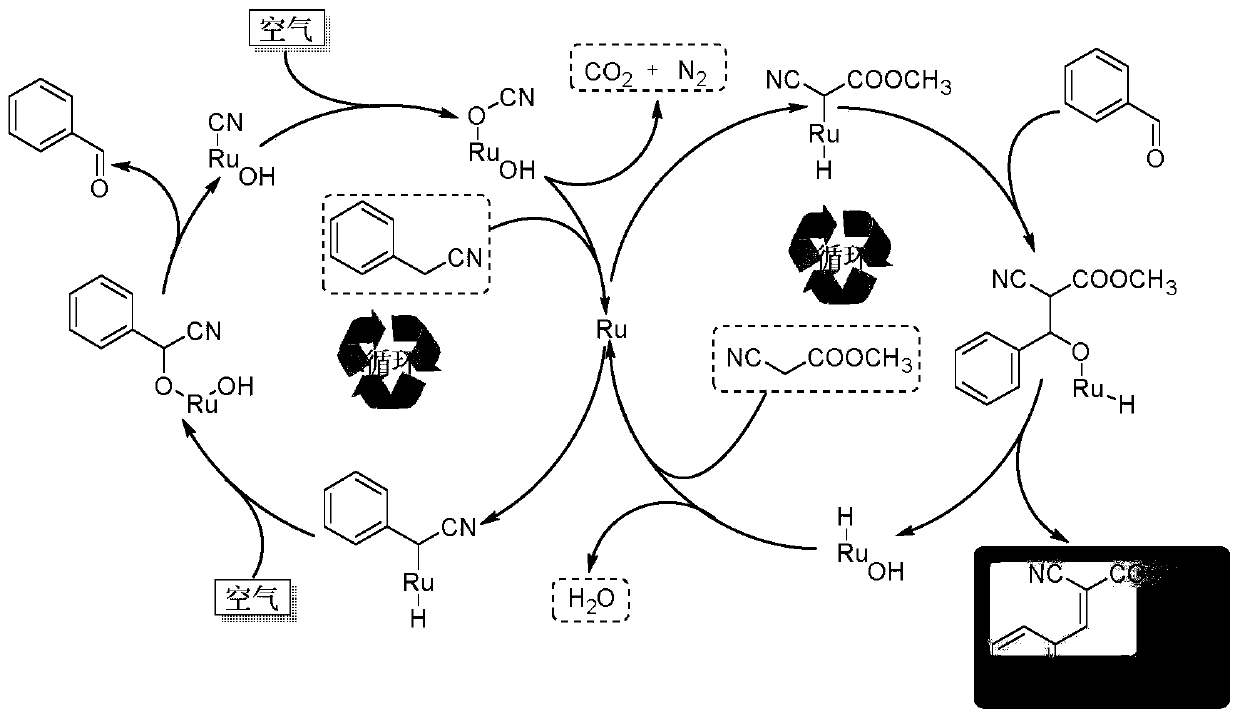

Method used

Image

Examples

Embodiment 1

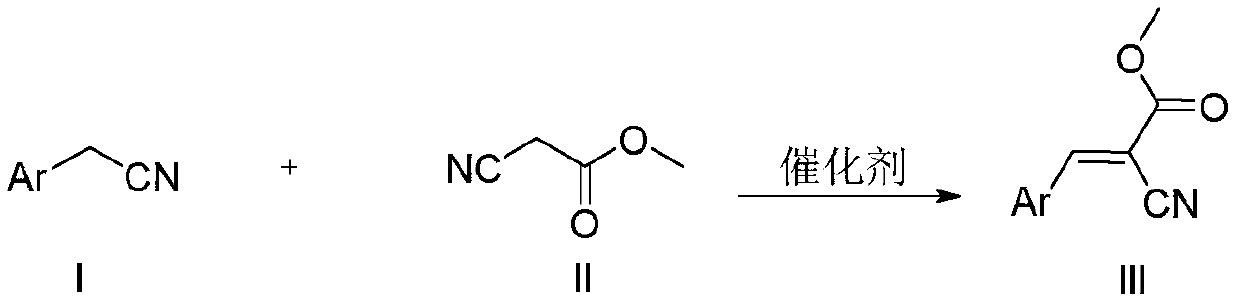

[0028] Embodiment 1: the preparation of acrylonitrile compound III-1

[0029] The reaction formula is as follows:

[0030]

[0031] Add 2.344g (20mmol) of phenylacetonitrile I-1, 0.2g (5‰mmol Ru) Ru / C catalyst and 9.910g (100mmol) of methyl cyanoacetate II to the reaction flask, and stir the reaction at 160°C under air atmosphere After 4 hours, it was detected by TLC that the reaction of benzyl nitrile was complete, and the reaction was stopped. The reaction was cooled to room temperature, the Ru / C catalyst was recovered by filtration, and the filtrate was distilled under reduced pressure at 10 mmHg (collecting fractions with a boiling point of 82°C to 84°C) to recover methyl cyanoacetate II for the next batch of reactions. 15 mL of ethanol was added to the distillation residue for recrystallization, and finally 3.668 g of solid was obtained by filtration, with a yield of 98.0% and a purity of 99.0%. The filtrate was evaporated by a rotary evaporator to recover ethanol for...

Embodiment 2

[0033] Embodiment 2: the preparation of acrylonitrile compound III-2

[0034] The reaction formula is as follows:

[0035]

[0036] Add 2.624g (20mmol) of o-tolueneacetonitrile I-2, 0.2g (5‰mmol Ru) Ru / C catalyst and 9.910g (100mmol) of methyl cyanoacetate II in the reaction flask, the following operations are implemented with example 1. Finally, 3.896 g of solid was obtained by filtration, with a yield of 96.8% and a purity of 99.0%. The filtrate was evaporated by a rotary evaporator to recover ethanol, which was used for the next batch of reactions. The structural representation of compound formula III-2 is as follows:

[0037] 1 H-NMR (CDCl 3 ,500MHz): δ8.54(s,1H),8.12(d,J=4.0Hz,2H),7.40-7.24(m,3H),3.91(s,3H),2.41(s,3H); 13 C-NMR (CDCl 3 ,125MHz): δ162.7,153.2,139.6,132.7,130,9,130,3,128.4,126.5,115.1,103.9,53.2,19.6; GC-MS(EI):m / z 201[M + ].

Embodiment 3

[0038] Embodiment 3: the preparation of acrylonitrile compound III-3

[0039] The reaction formula is as follows:

[0040]

[0041] In the reaction flask, add 2.624g (20mmol) of p-toluene acetonitrile I-3, 0.4g (10‰mmol Ru) Ru / C catalyst and 9.910g (100mmol) of methyl cyanoacetate II, under air atmosphere 160 The reaction was stirred at °C for 3 h, and the following operations were the same as in Example 1. Finally, 3.976 g of solids were obtained by filtration, with a yield of 98.8% and a purity of 99.0%. The filtrate was evaporated by a rotary evaporator to recover ethanol for use in the next batch of reactions. The structural representation of compound formula III-3 is as follows:

[0042] 1H-NMR (CDCl 3 ,500MHz):δ8.21(s,1H),8.89(d,J=8.0Hz,2H),7.29(d,J=8.0Hz,2H),3.92(s,3H),2.43(s,3H) ; 13 C-NMR (CDCl 3 ,125MHz): δ163.2,155.2,144.8,131.3,130.0,128.8,115.7,101.1,53.3,21.8; GC-MS(EI):m / z201[M + ].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com