Polypropylene composite resin composition with continuously maintained deodorizing capability and aromaticity

A polypropylene polymer and composite resin technology, which is applied in the field of polypropylene composite resin composition, can solve problems such as poor physical properties and achieve the effect of a comfortable environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

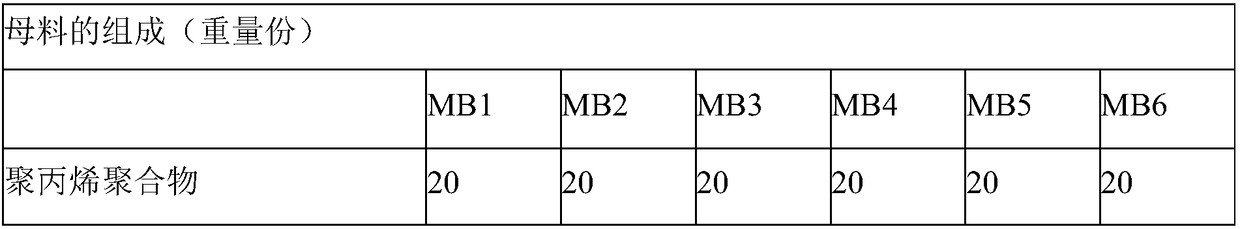

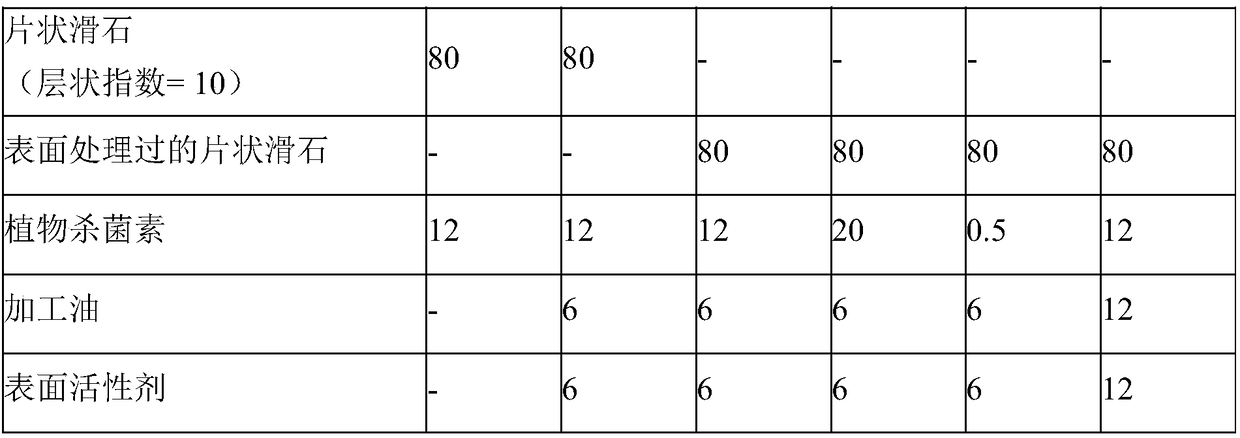

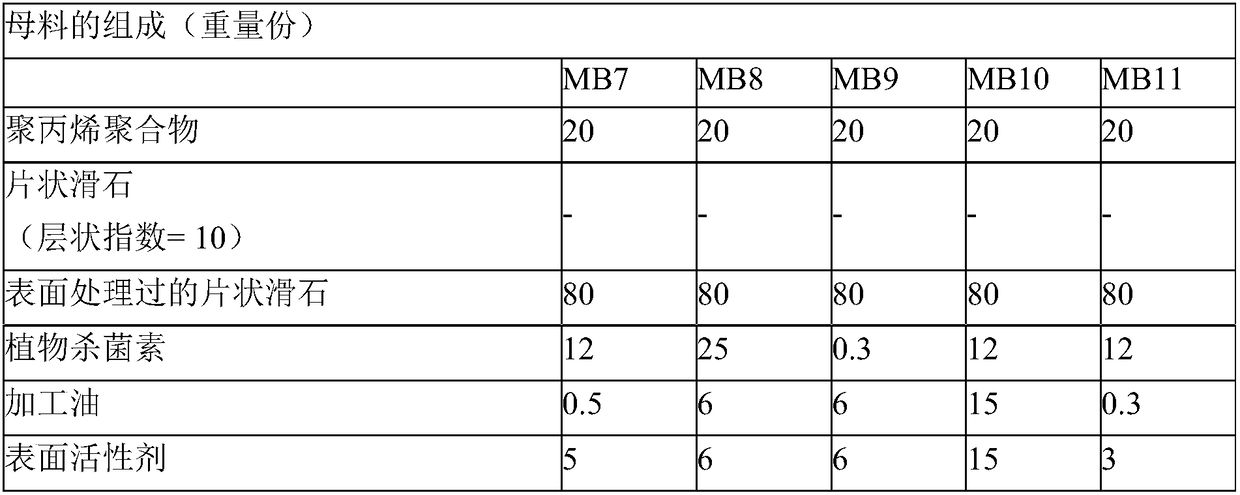

Method used

Image

Examples

Embodiment 1

[0062] Example 1. Preparation of composite resin samples using masterbatch

[0063] 65 parts by weight of polypropylene polymer, 10 parts by weight of thermoplastic elastomer and 25 parts by weight of the MB1 masterbatch prepared in the preparation example were physically mixed and extruded at 180-210 °C by using a twin-screw extruder with a diameter of 40 mm. Extruded below to prepare pellets. The prepared pellets were injection molded into samples at 180-210°C to evaluate physical properties.

Embodiment 2

[0064] Example 2. Preparation of Composite Resin Samples Using Masterbatch

[0065] Samples for evaluating physical properties were prepared in the same manner as in Example 1 except that 25 parts by weight of master batch MB2 was used instead of master batch MB1.

Embodiment 3

[0066] Example 3. Preparation of Composite Resin Samples Using Masterbatch

[0067] Samples for evaluation of physical properties were prepared in the same manner as in Example 1 except that 25 parts by weight of master batch MB3 was used instead of master batch MB1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com