Novel environment-friendly foamed material as well as preparation method and foaming process thereof

A foaming material and environmental protection technology, applied in the field of new environmentally friendly foaming materials and their preparation, can solve the problems of low quality and mechanical properties of foamed materials, uneven cell size, etc., and achieve wide market value, sufficient toughness, and strength. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

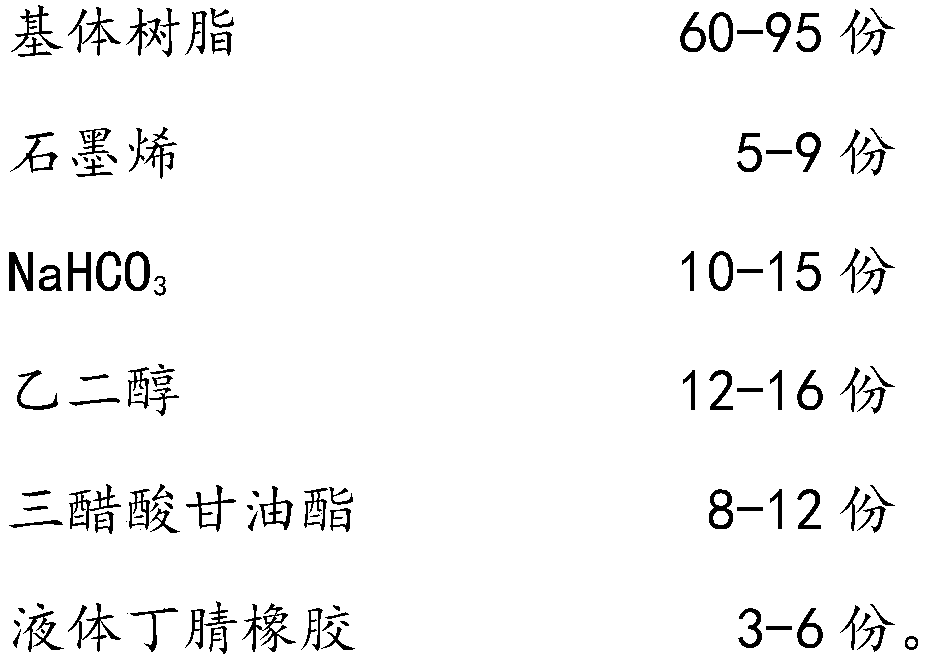

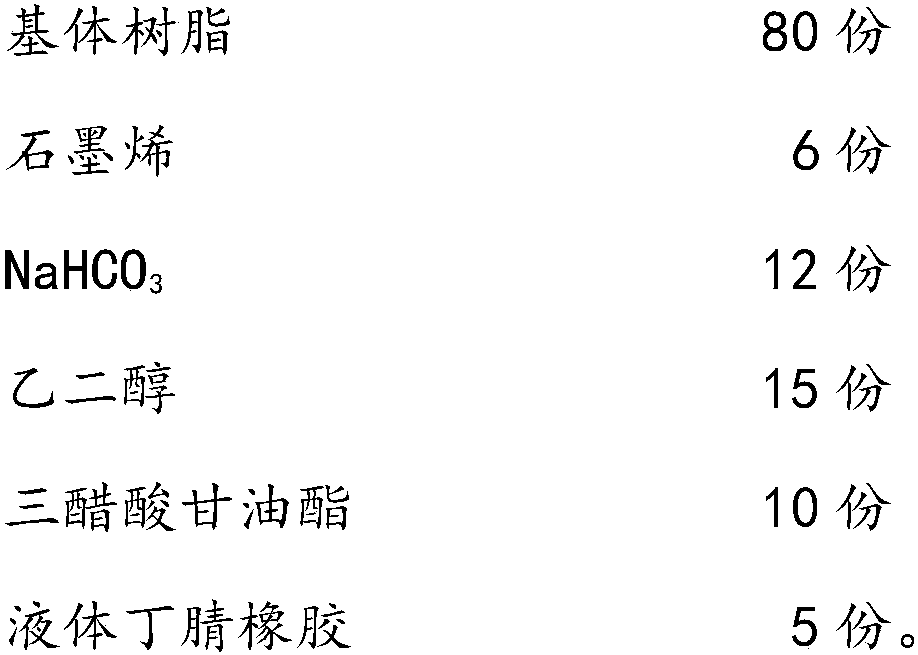

Method used

Image

Examples

Embodiment 1

[0024] Step a, 20 parts of polystyrene resin, 5 parts of graphene and 8 parts of glycerol triacetate were mixed and stirred at a speed of 500 rpm for 1.5 hours at 150°C to form a mixture M1;

[0025] Step b. Add 4 parts of liquid nitrile rubber and 40 parts of polystyrene resin to the mixture M1, and stir at a speed of 80 rpm for 1.0 h under the condition of 95°C-115°C to form a mixture M2;

[0026] Step c, 12 parts of ethylene glycol and 10 parts of NaHCO 3 After mixing at room temperature and stirring at a speed of 50 rpm for 10 minutes, add it to the mixture M2, stir at a speed of 40 rpm at 50 ° C for 1.0 h, extrude and granulate and cool to room temperature to obtain a new environmentally friendly foaming material;

[0027] Step d, placing the new environmentally friendly foaming material in the foaming unit for heating and melting;

[0028] Step e, CO 2 The foaming gas is injected into the end of the unit, and after being fully mixed, it is extruded through a mold, cool...

Embodiment 2

[0030] Step a, 30 parts of LLDPE, 9 parts of graphene and 12 parts of glycerol triacetate were mixed and stirred at a speed of 400 rpm for 1.5 hours at 140°C to form a mixture M1;

[0031] Step b, 6 parts of liquid nitrile rubber and 40 parts of LDPE are added to the mixture M1, and stirred at 100 rpm for 1.0 h at 105°C to form a mixture M2;

[0032] Step c, 16 parts of ethylene glycol and 15 parts of NaHCO 3 Mix at room temperature and stir at 60rpm for 5-10min, then add to the mixture M2, stir at 35rpm at 40°C for 1.0h, pass CO into the stirring vessel 2 15 minutes, extruded and granulated, cooled to room temperature, and a new environmentally friendly foam material was obtained.

[0033] Step d, placing the new environmentally friendly foaming material in the foaming unit for heating and melting;

[0034] Step e, CO 2 Mix it with butane at a ratio of 2:3 and inject it into the end of the unit. After fully mixing, the mixture is ultrasonically treated for 15 minutes, ext...

Embodiment 3

[0036] Step a, 25 parts of LLDPE, 8 parts of graphene and 10 parts of glycerol triacetate were mixed and stirred at a speed of 400 rpm for 0.95 h at 130°C to form a mixture M1;

[0037] Step b. Add 6 parts of liquid nitrile rubber and 52 parts of LDPE to the mixture M1, and stir at 90 rpm for 1.0 h under the condition of 95°C-115°C to form the mixture M2;

[0038] Step c, 15 parts of ethylene glycol and 12 parts of NaHCO 3 Mix at room temperature and stir at 30-60rpm for 5-10min, then add to the mixture M2, stir at 45°C at 40rpm for 1.0h, pass CO into the stirring vessel 2 After 20 minutes, extrude and granulate and cool to room temperature to obtain a new environmentally friendly foaming material.

[0039] Step d, placing the new environmentally friendly foaming material in the foaming unit for heating and melting;

[0040] Step e, CO 2 Mix it with butane at a ratio of 2:3 and inject it into the end of the unit. After fully mixing, the mixture is ultrasonically treated fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com