Low-wear scratch-resistant ABS material and preparation method thereof

An ABS material, scratch-resistant technology, applied in the field of plastic processing, to achieve the effect of less components, low production cost and easy industrial production

Inactive Publication Date: 2018-06-15

TIANJIN UNIV OF SCI & TECH

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, scratch-resistant ABS materials only focus on improving the surface hardness of ABS, and there are few improvements in reducing material wear.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~5

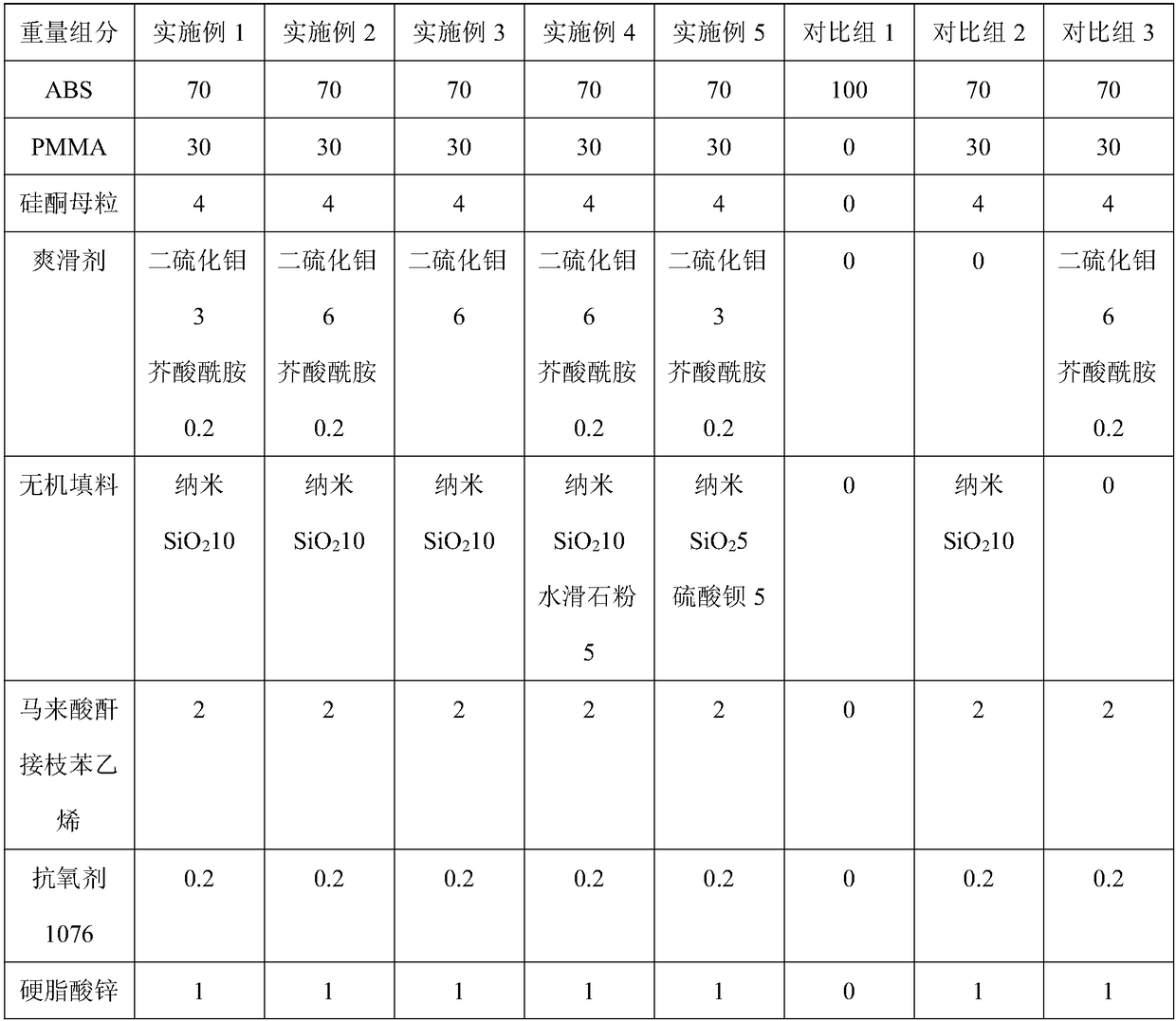

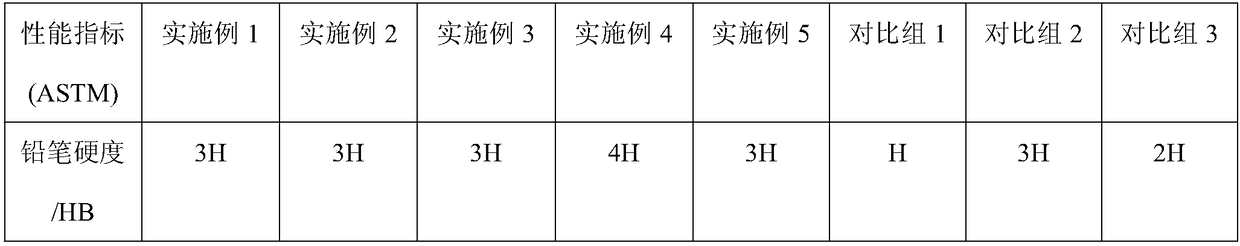

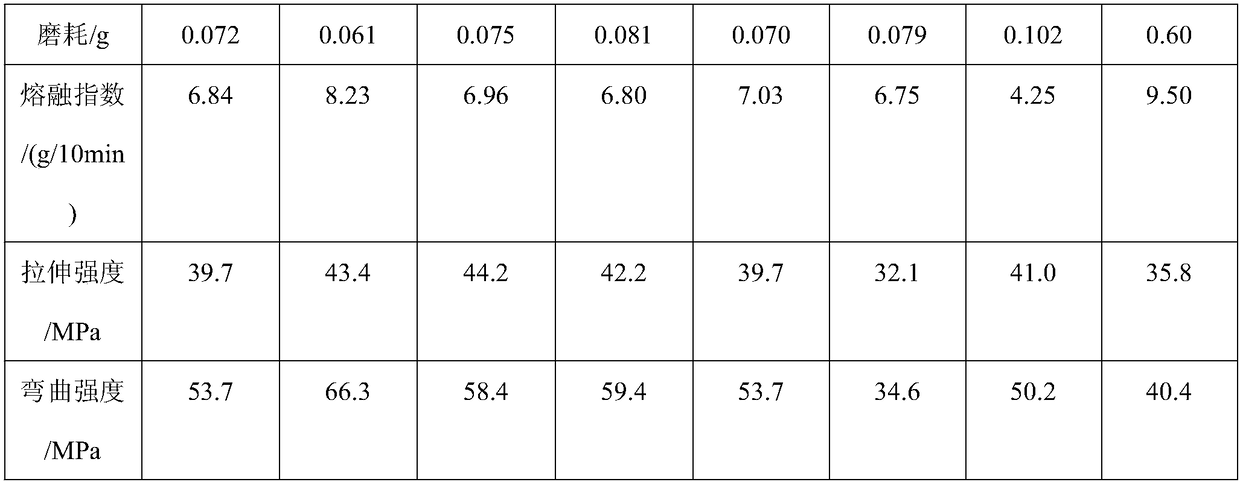

[0025] Embodiment 1~5, comparison group 1~3 formula

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a low-wear scratch-resistant ABS material and a preparation method thereof. Blending of ABS with PMMA and addition of an inorganic filler, a slip agent and the like improve the resistance of the ABS to wear and scratch in order to solve the problem of poor wear resistance of the ABS. The low-wear scratch-resistant ABS material comprises, by weight, 70-90 parts of ABS resin, 10-30 parts of polymethyl methacrylate, 1-5 parts of maleic anhydride grafted styrene, 0.2-2 parts of a lubricant, 0.2-2 parts of an antioxidant, 0.5-10 parts of the slip agent, 0.5-5 parts of silicone master batches and 2-20 parts of the inorganic filler. The prepared ABS has a high pencil hardness, and has a lower wear resistance than the ordinary ABS, and the mechanical properties and the processing fluidity are not significantly less than those of the ordinary ABS.

Description

technical field [0001] The invention belongs to the technical field of plastic processing and relates to ABS, in particular to a low-wear and scratch-resistant ABS material and a preparation method thereof. Background technique [0002] At present, domestic research on scratch-resistant materials mainly focuses on polypropylene materials for automobiles, and less attention is paid to the scratch resistance of ABS. ABS is widely used in electronic appliances, instrumentation, automobiles and other fields because of its excellent surface gloss, processing flow properties, physical and mechanical properties and chemical resistance properties. At present, the methods commonly used to improve the scratch resistance of ABS surface include surface electroplating method and surface coating hardening method. These methods not only have complex procedures, high pollution and high processing costs, but also have the disadvantages of being greatly affected by product size and appearanc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L55/02C08L33/12C08L51/00C08K13/02C08K5/20C08K3/30B29B9/06B29C47/92B29C48/92

CPCB29B9/06B29C48/92B29C2948/92704C08K2003/3009C08L55/02C08L2205/035C08L33/12C08L51/003C08K13/02C08K5/20C08K3/30

Inventor 崔永岩杨瀚张丹梁书然

Owner TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com