Environment-friendly efficient heat transfer drying drum

An efficient and environmentally friendly technology, applied in drying, dryers, heating devices, etc., can solve the problems of exhaust gas pollution, unrecyclable steam, large energy consumption, etc., to reduce energy consumption, reduce energy consumption, The effect of high temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

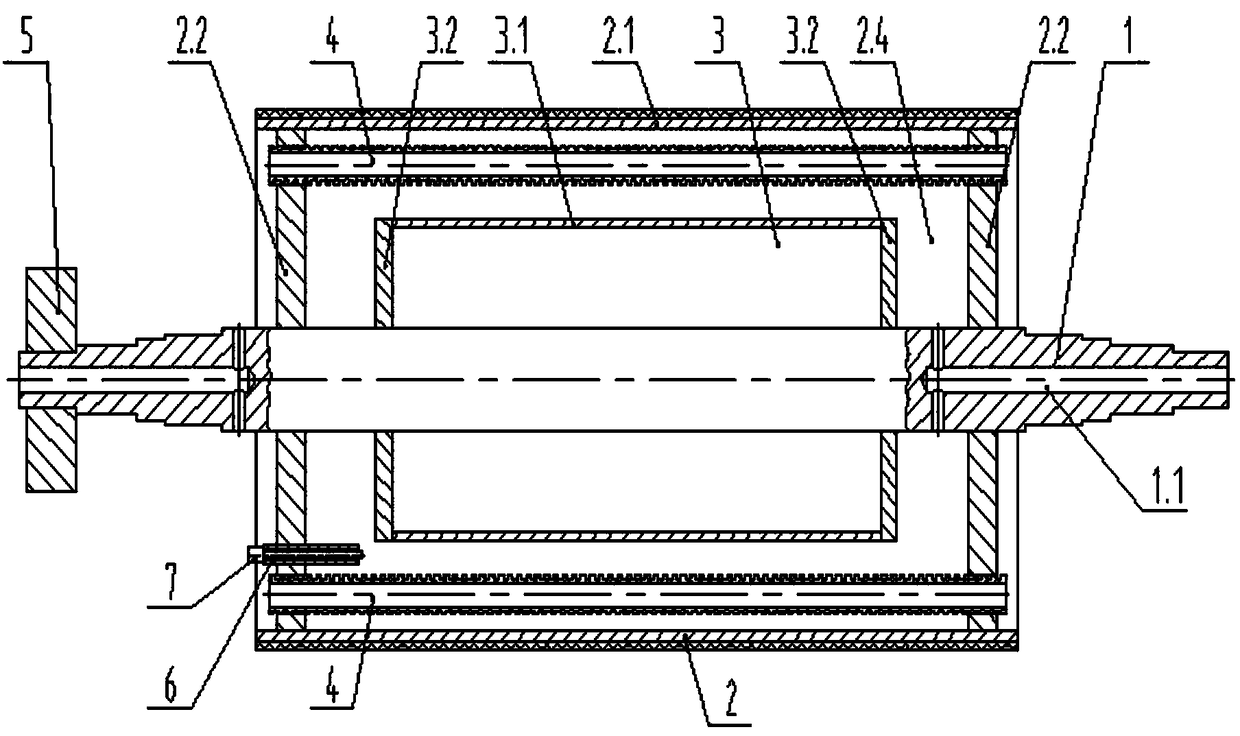

[0019] The environment-friendly and high-efficiency heat transfer drying cylinder shown in the attached figure includes a mandrel 1, an outer cylinder 2, a conductive slip ring 5, a number of heat transfer tubes 4, and the outer wall of the heat transfer tube 4 is provided with a spiral groove; the outer cylinder 2 includes a cylinder section I2.1 , The circular sealing plate I2.2 that is sealed and connected to the two ends of the cylindrical section I2.1, the outer wall of the cylindrical section I2.1 is provided with polyether ether ketone coating; the mandrel 1 is placed flat, and runs through the circular sealing plate I2.2 at both ends , and is sealed and fixedly connected with the circular sealing plate I 2.2 to form a closed cavity 2.4; the right end of the mandrel 1 is provided with an oil delivery hole 1.1 connected to the clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com