Electrochromic fiber with coaxial structure and application of electrochromic fiber

An electrochromic, coaxial structure technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of poor wearing experience and poor fiber durability, and achieve the effect of good durability and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

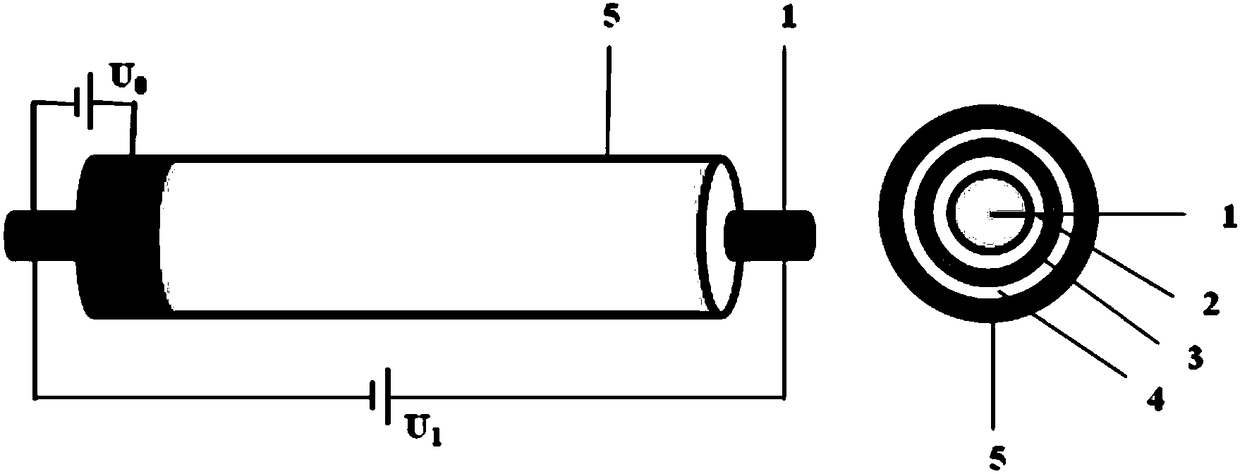

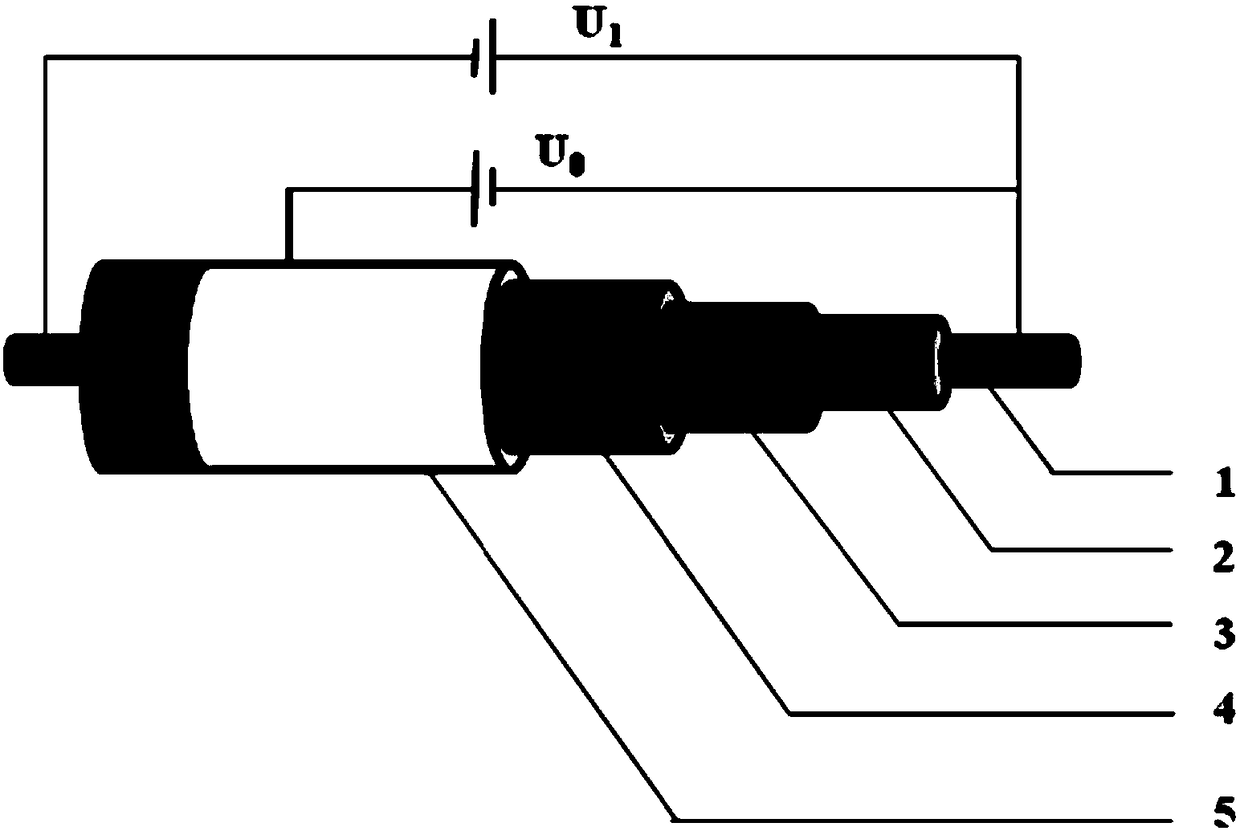

[0028] see figure 1 with figure 2 , figure 1 It is a structural schematic diagram of the coaxial electrochromic fiber of the present embodiment, figure 2 It is a schematic diagram of the hierarchical structure of the electrochromic fiber with coaxial structure peeled off layer by layer in this embodiment. The electrochromic fiber of the coaxial structure includes a conductive support fiber 1 , a transparent transition layer 2 , a color-changing layer 3 , an electrolyte layer 4 and a conductive high polymer coating layer 5 sequentially from inside to outside.

[0029] In this embodiment, the conductive support fiber 1 is a light-colored material, which can be obtained by interweaving metal-plated fabrics, surface-impregnated conductive polymer fabrics, metal-plated conductive fibers, or pure metal fibers and ordinary fibers. Fabric and pure metal fiber constitute at least one of the fabric, and its surface resistance is preferably 0.01-1000Ω.

[0030] The transparent tran...

Embodiment 2

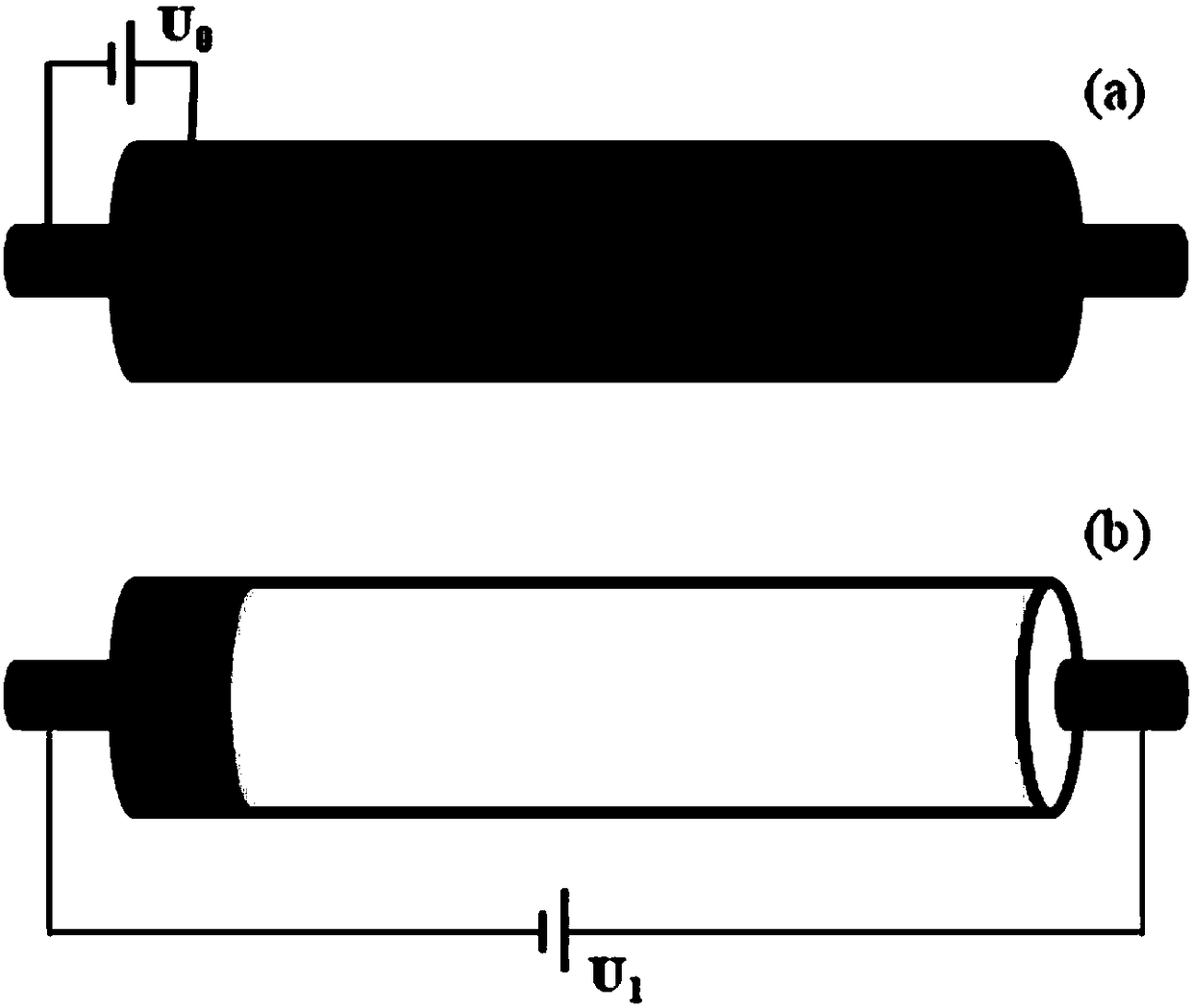

[0042] This embodiment provides a kind of textile, and it adopts conventional method to weave by the electrochromic fiber of coaxial structure in embodiment 1 and makes, and its working state is as follows Figure 4 shown. The textile has the advantages of long service life and good durability, and can be used in smart clothing and wearable static displays.

[0043] Compared with the prior art, the electrochromic fiber of the coaxial structure of the present invention is based on the axial migration of ions in the color-changing layer under the drive of the working voltage to switch between coloring and fading, thereby avoiding the occurrence of ion migration from the color-changing layer. Therefore, in the case of no ion storage layer, this electrochromic fiber also has the advantage of good durability, and has a good application prospect in the textile market and wearable static display.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com