Microwave sintered NdFeB magnet and preparation method thereof

A microwave sintering and magnet technology, applied in the fields of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve problems such as the influence of the use range of magnets, and achieve the effect of enhancing the effect of micropowder lubrication, isolating air, and improving sintering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

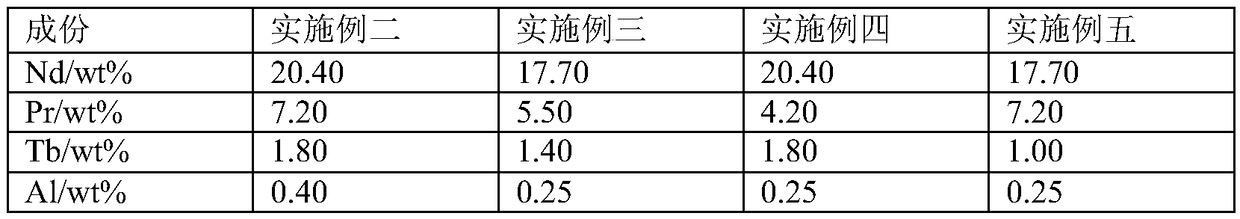

Examples

Embodiment 1

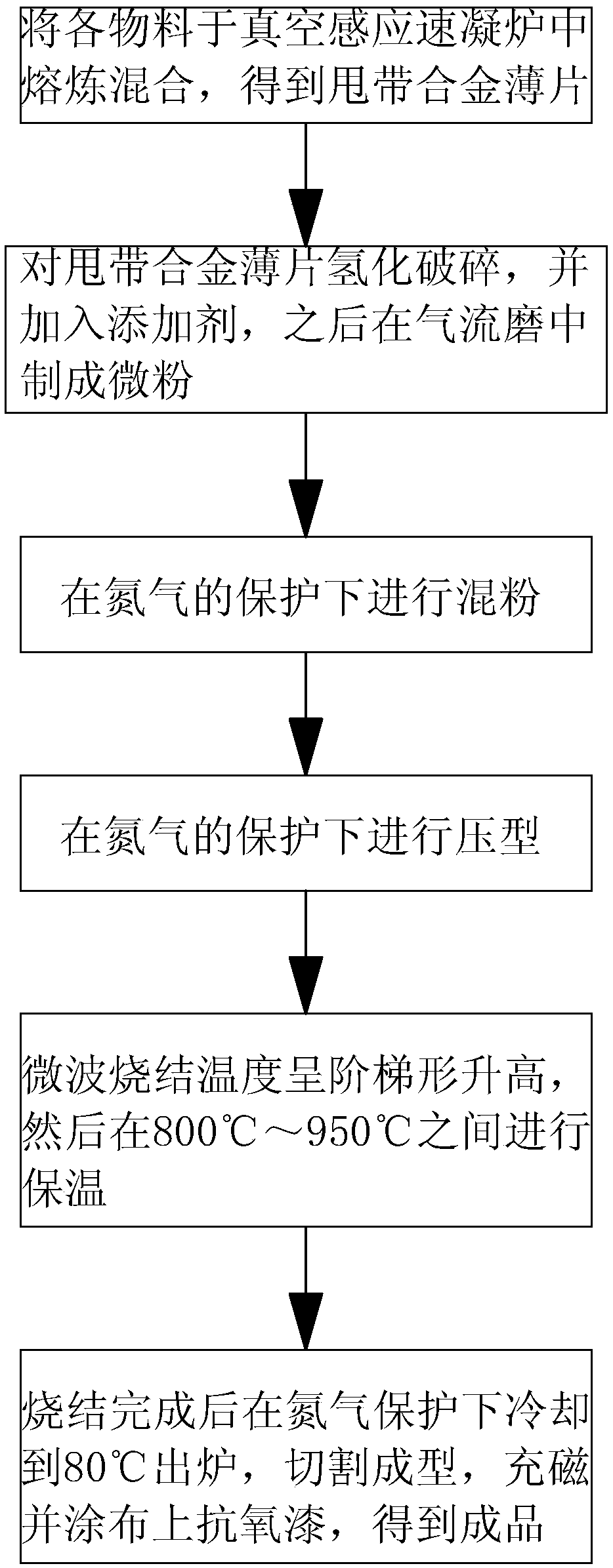

[0051] A preparation method of sintered NdFeB magnet, comprising the following steps:

[0052] Step 1, 15.0wt% Nd, 4.2wt% Pr, 1.0wt% Tb, 0.1wt% Co, 0.94wt% B, 0.05% Ag, 0.08wt% Cu, 0.04wt% Si, 1.2wt% Zn, 0.6wt% %Sn, 0.82wt% Zr, 74.59wt% Fe and non-removable impurities are added to the vacuum induction quick solidification furnace for melting, and the melting temperature is controlled at 2800 ° C. Here, Cu and Si are made of Cu-Si master alloy Added to the vacuum induction quick-setting furnace;

[0053] Step 2. After all the substances in S1 are melted, add 0.05wt% La, 0.03wt% Eu, 0.1wt% Al, 0.06wt% In, 1.10wt% Ce and 0.04wt% Ga to the vacuum induction quick setting Mix and smelt together with the previous material in the furnace to obtain stripped alloy flakes;

[0054] Step 3: Break the stripped alloy flakes in a hydrogenation furnace first, then add a mixture of methyl acetate, polyethylene oxide monofatty acid ester and graphite, and then make fine powder in a jet mill, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com