Method for removing surface pollution of polished silicon wafer with normal-temperature HF acid

A silicon wafer surface, room temperature technology, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., to achieve the effect of being conducive to cleaning, moderating the reaction, and enhancing the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] The concrete method that the present invention introduces is as follows:

[0027] 1. Chemical reagents: 49%-51% hydrofluoric acid stock solution, surface active reagent (English abbreviation TSC-1) is added in the cleaning tank according to a certain proportion.

[0028] 2. Two tanks are added in front of the traditional standard cleaning machine, namely the chemical solution tank made of Teflon and the pure water tank made of quartz.

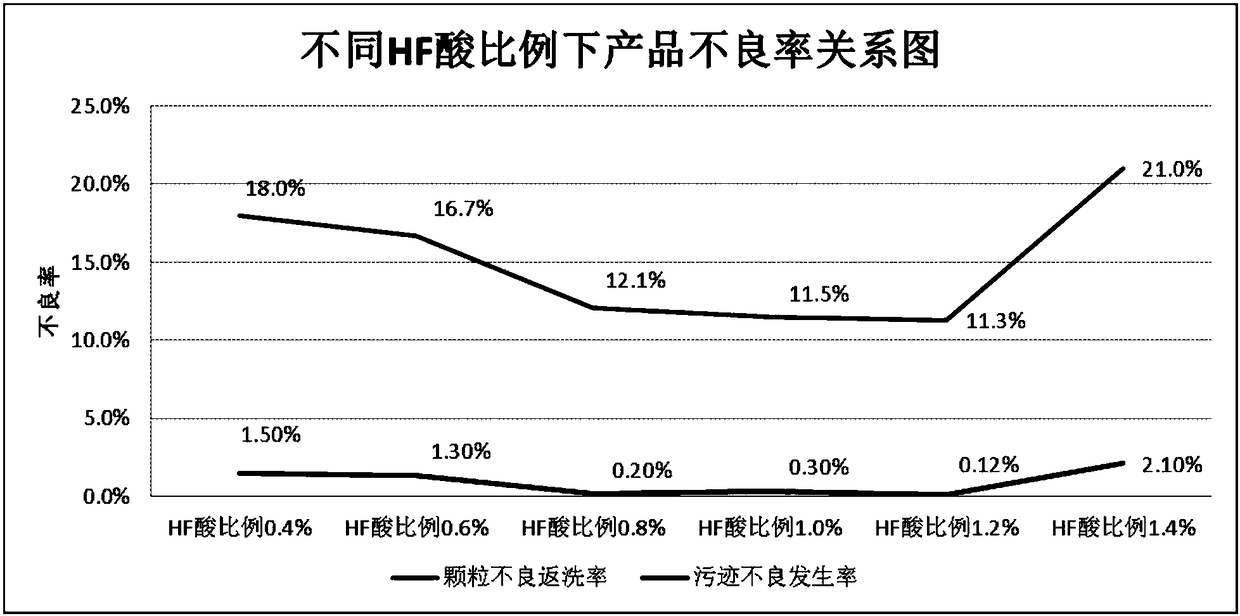

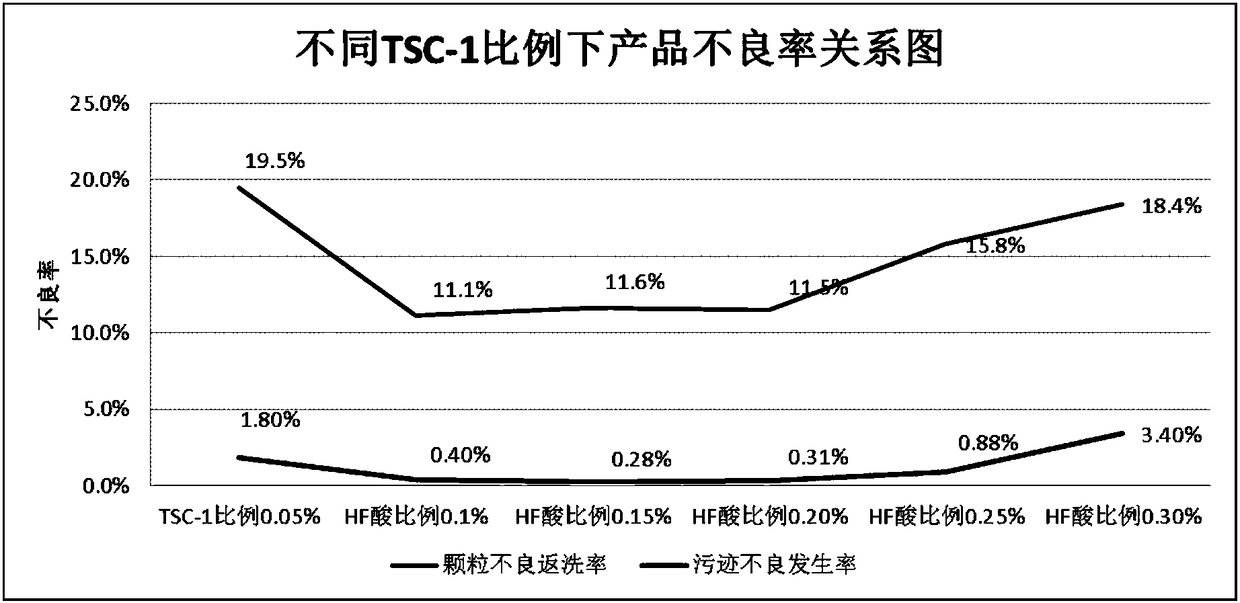

[0029] 3. Stock solution mixing: 49% hydrofluoric acid stock solution is weighed according to the ratio of 0.8%-1.2% of the liquid tank volume and placed in a weighing bucket; Weigh the stock solution at a ratio of 0.1-0.2% of the volume and place it in a weighing bucket.

[0030] 4. Mix the two solutions and put them into the Teflon liquid medicine tank and mix them well.

[0031] 5. Silicon wafers can be cleaned at room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com