Double-sided power generation cadmium telluride thin film solar cell and preparation method thereof

A solar cell and cadmium telluride technology, which is applied in the field of solar cells, can solve the problems that the absorption layer cannot absorb sunlight from the back side, and the cadmium telluride solar cell cannot achieve double-sided power generation, etc., so as to improve Voc and FF, and improve performance. , Improve the effect of the built-in electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

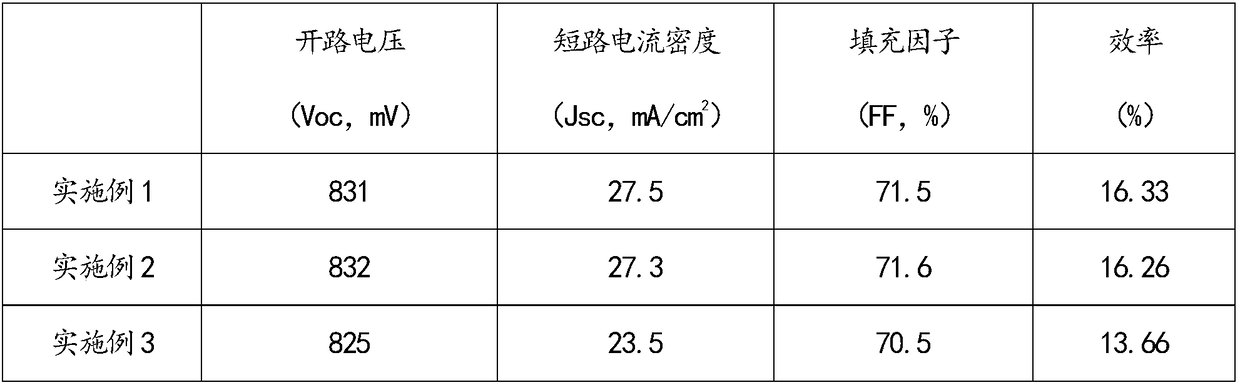

Embodiment 1

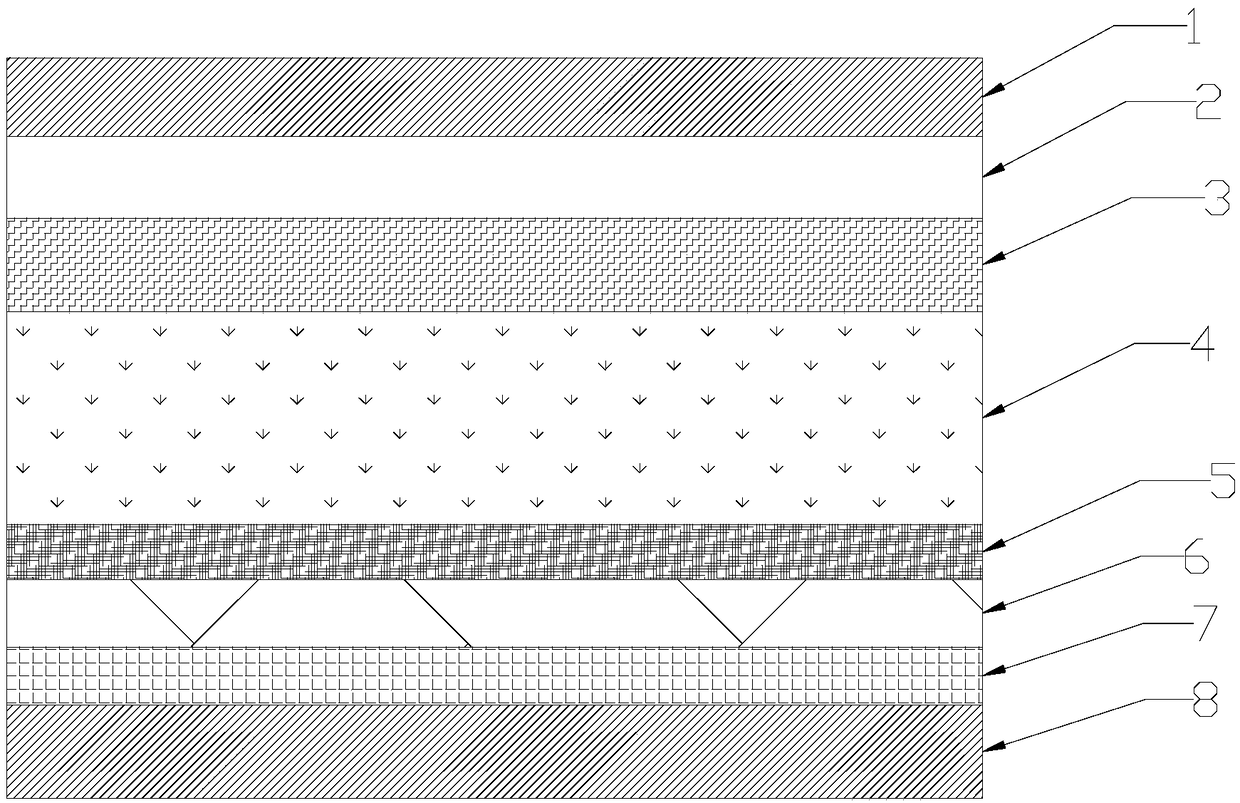

[0030] A method for preparing a cadmium telluride thin-film solar cell generating electricity on both sides, comprising the following steps:

[0031] (1) Deposit fluorine-doped tin oxide on a glass substrate to form a transparent conductive film layer, and the deposition temperature condition is lower than 400°C;

[0032] (2) Depositing cadmium sulfide on the transparent conductive film layer to form a window layer, the deposition temperature condition is lower than 250°C;

[0033] (3) Depositing cadmium telluride on the window layer to form an absorber layer, the deposition temperature condition is lower than 300°C;

[0034] (4) Depositing cuprous thiocyanate on the absorber layer to form a back contact layer, the deposition temperature condition is lower than 300°C;

[0035] (5) Depositing tungsten-doped indium oxide on the back contact layer to form a back electrode layer, the deposition temperature condition is lower than 300°C;

[0036] (6) Laminate and encapsulate the ...

Embodiment 2

[0039] A method for preparing a cadmium telluride thin-film solar cell generating electricity on both sides, comprising the following steps:

[0040] (1) Deposit fluorine-doped tin oxide on a glass substrate to form a transparent conductive film layer, and the deposition temperature condition is lower than 400°C;

[0041] (2) Depositing cadmium sulfide on the transparent conductive film layer to form a window layer, the deposition temperature condition is lower than 250°C;

[0042] (3) Depositing cadmium telluride on the window layer to form an absorber layer, the deposition temperature condition is lower than 300°C;

[0043] (4) Depositing cuprous thiocyanate on the absorber layer to form a back contact layer, the deposition temperature condition is lower than 300°C;

[0044] (5) Depositing tungsten-doped indium oxide on the back contact layer to form a back electrode layer, the deposition temperature condition is lower than 300°C;

[0045] (6) Laminate and encapsulate the ...

Embodiment 3

[0047] Embodiment 3 (comparative example):

[0048] A method for preparing a cadmium telluride thin film solar cell, comprising the following steps:

[0049] (1) Deposit fluorine-doped tin oxide on a glass substrate to form a transparent conductive film layer, and the deposition temperature condition is lower than 400°C;

[0050] (2) Depositing cadmium sulfide on the transparent conductive film layer to form a window layer, the deposition temperature condition is lower than 250°C;

[0051] (3) Depositing cadmium telluride on the window layer to form an absorber layer, the deposition temperature condition is lower than 300°C;

[0052] (4) Deposit carbon paste on the absorber layer to form a back contact layer, and the deposition temperature condition is lower than 300°C;

[0053] (5) Depositing metallic nickel on the back contact layer to form a back electrode layer, the deposition temperature condition is lower than 300°C;

[0054] (6) Laminate and encapsulate the deposited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com