Polyurethane elastomer composition for floor coating and preparation method of polyurethane elastomer composition

A polyurethane elastomer and floor coating technology, which is applied in the field of polyurethane synthesis, can solve the problems of epoxy floor coatings such as brittleness and cracking, poor UV resistance, and poor weather resistance, and achieve scientific and reasonable preparation methods, high transparency, Good anti-yellowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

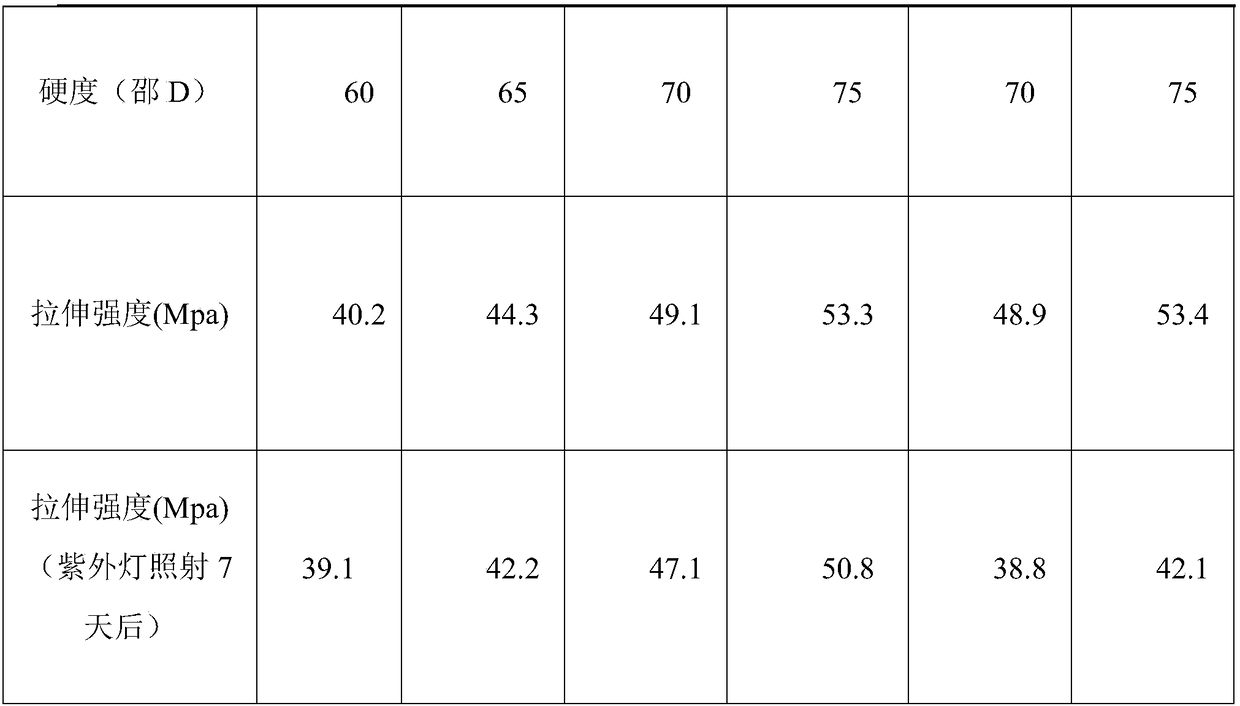

Embodiment 1

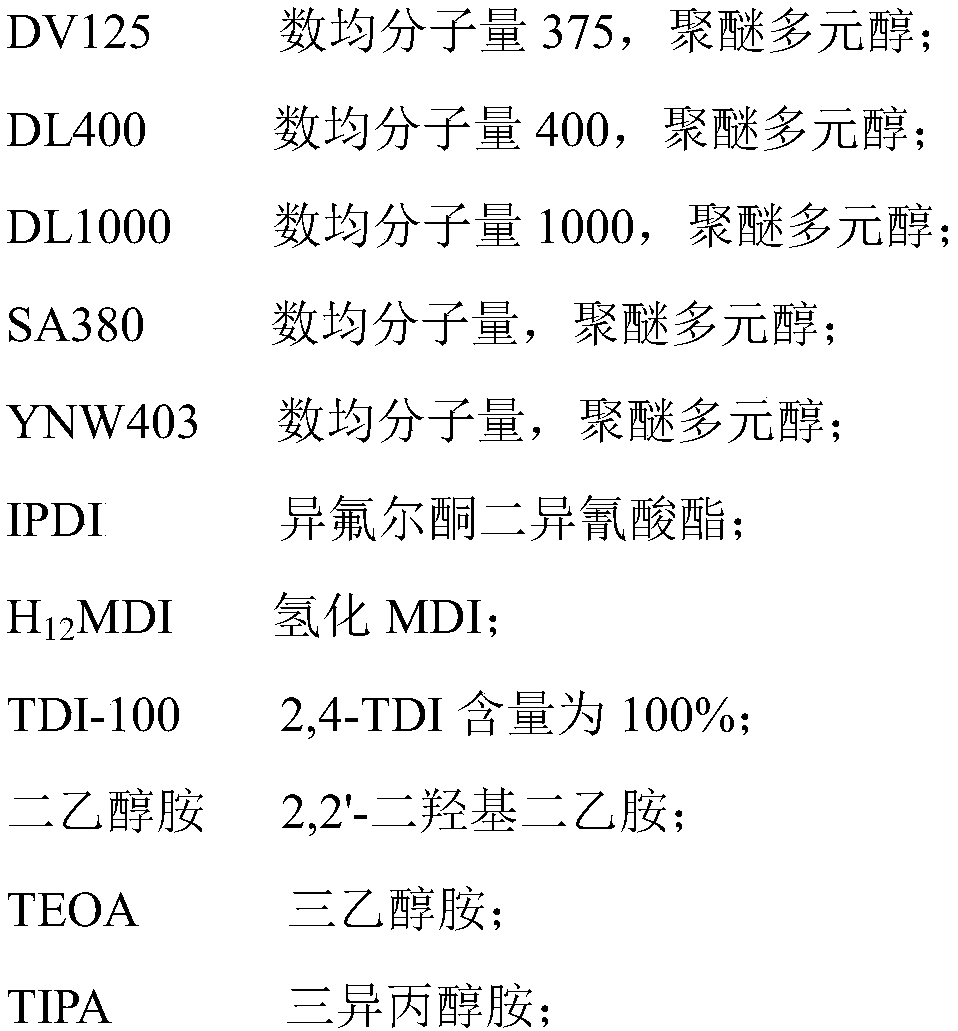

[0029] Prepolymer components: polyether polyol DV125 20.9%, IPDI 79.1%, react at 90°C for 7 hours, remove air bubbles under a vacuum of -0.095MPa, and obtain a prepolymer with an isocyanate content of 22.4%.

[0030] The prepolymer component and diethanolamine are mixed at a ratio of 100:16.5 at room temperature. After stirring evenly, spray it on the ground, react and solidify for 16 hours at room temperature, and then form it.

Embodiment 2

[0032] Prepolymer components: polyether polyol SA380 9.6%, polyether polyol DL1000 9.6%, H 12 MDI80.8%, react at 90°C for 7 hours, remove air bubbles under vacuum degree -0.095MPa, and obtain a prepolymer with an isocyanate content of 22.4%.

[0033] The prepolymer component and diethanolamine are mixed at a ratio of 100:28 at room temperature, stirred evenly, sprayed on the ground, reacted and cured for 15 hours at room temperature, and then formed.

Embodiment 3

[0035] Prepolymer component: polyether polyol SA380 15.9%, H 12 MDI84.1%, react at 90°C for 7 hours, remove air bubbles under vacuum degree -0.095MPa, and obtain a prepolymer with an isocyanate content of 22.4%.

[0036] The prepolymer component and diethanolamine are mixed at a ratio of 100:26.5 at room temperature, stirred evenly, sprayed on the ground, reacted and cured for 15 hours at room temperature, and then formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com