MoS2-SnO2-carbon fiber composite material and preparation method thereof

A mos2-sno2-, composite material technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of limited material properties and applications, high temperature environment, cumbersome preparation process, etc., to achieve accelerated carrier mobility, The effect of increasing the specific surface area and increasing the effective sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

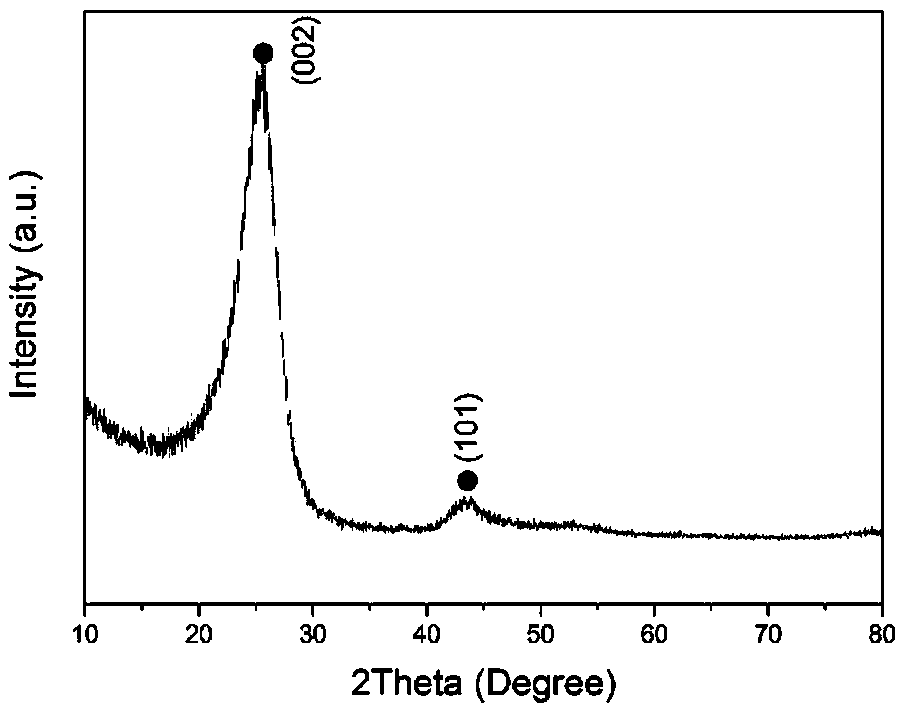

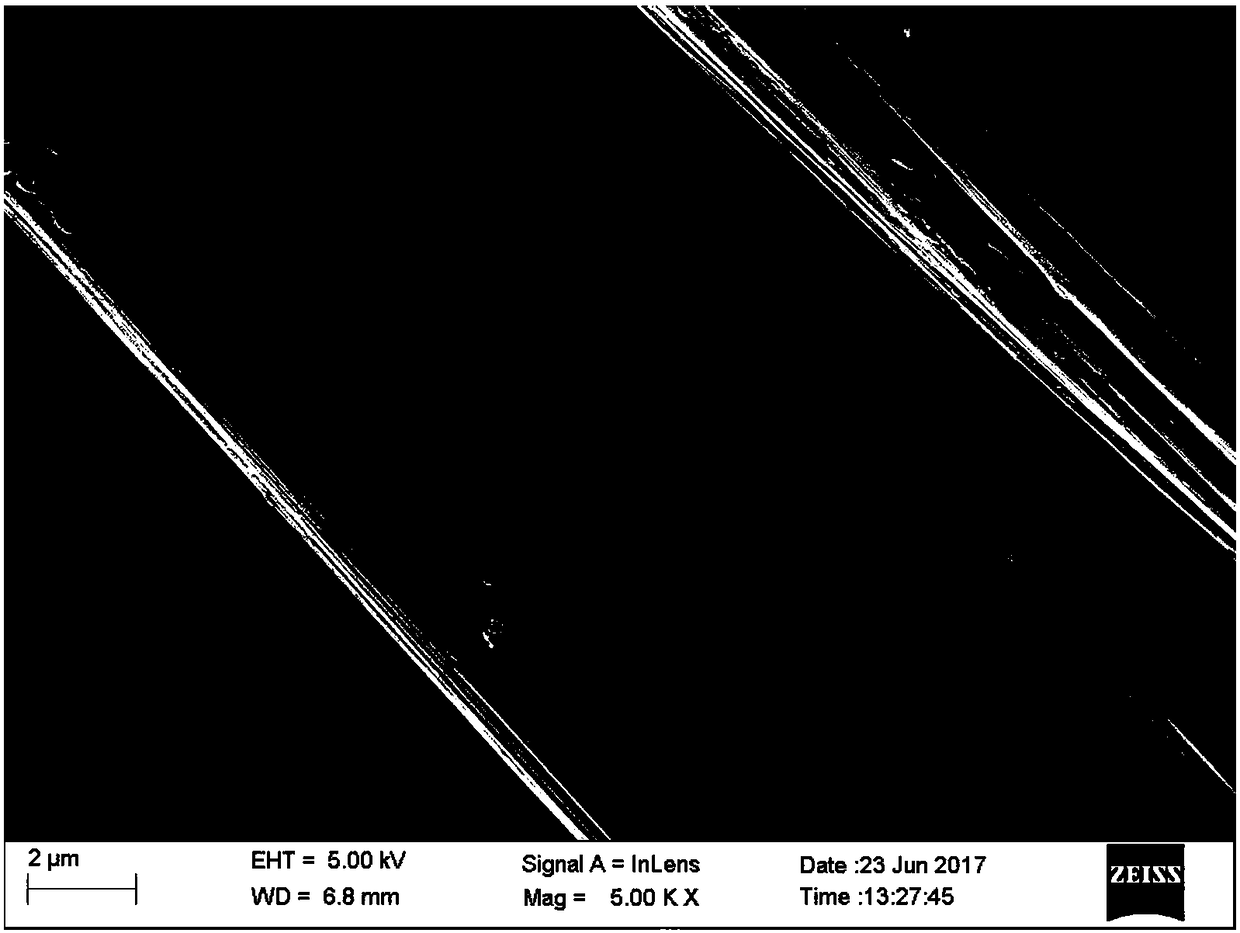

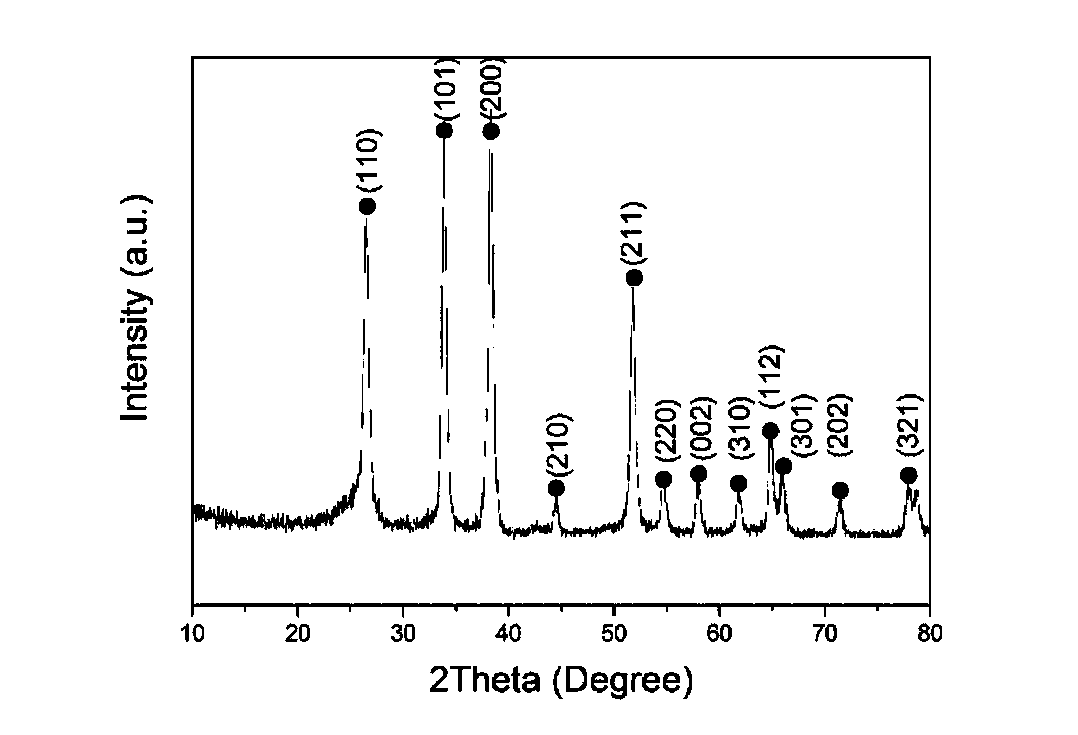

[0049] First, in this experiment, tin tetrachloride (SnCl 4 ·5H 2 O) and sodium hydroxide (NaOH) as reaction source materials to prepare SnO on a flexible substrate carbon cloth 2 . The specific operation process is as follows: use an electronic balance to weigh a certain amount of tin tetrachloride (SnCl 4 ·5H 2 O) and sodium hydroxide (NaOH), respectively configure 0.04mol / L tin tetrachloride solution and 0.56mol / L NaOH solution, and then slowly titrate the prepared NaOH solution into the tin tetrachloride solution to make it Mix well and finally form a stable and uniform precursor solution. Slowly pour the solution into a 50ml autoclave containing carbon cloth, place it in an oven, and react at 200°C for 16 hours. After the reaction is over, take out the carbon cloth and wash it with deionized water several times. Arrange the carbon to dry at 60℃ to obtain SnO 2 Coated carbon fiber composite material.

[0050] SnO 2 -The carbon fiber membrane material is washed several times ...

Embodiment 2

[0053] First, in this experiment, tin tetrachloride (SnCl 4 ·5H 2 O) and sodium hydroxide (NaOH) as reaction source materials to prepare SnO on a flexible substrate carbon cloth 2 . The specific operation process is as follows: use an electronic balance to weigh a certain amount of tin tetrachloride (SnCl 4 ·5H 2 O) and sodium hydroxide (NaOH), respectively configure 0.04mol / L tin tetrachloride solution and 0.56mol / L NaOH solution, and then slowly titrate the prepared NaOH solution into the tin tetrachloride solution to make it Mix well and finally form a stable and uniform precursor solution. Slowly pour the solution into a 50ml autoclave containing carbon cloth, place it in an oven, and react at 200°C for 16 hours. After the reaction is over, take out the carbon cloth and wash it with deionized water several times. Arrange the carbon to dry at 60℃ to obtain SnO 2 Coated carbon fiber composite material.

[0054] SnO 2 -The carbon fiber membrane material is washed several times ...

Embodiment 3

[0057] First, in this experiment, tin tetrachloride (SnCl 4 ·5H 2 O) and sodium hydroxide (NaOH) as reaction source materials to prepare SnO on a flexible substrate carbon cloth 2 . The specific operation process is as follows: use an electronic balance to weigh a certain amount of tin tetrachloride (SnCl 4 ·5H 2 O) and sodium hydroxide (NaOH), respectively configure 0.04mol / L tin tetrachloride solution and 0.56mol / L NaOH solution, and then slowly titrate the prepared NaOH solution into the tin tetrachloride solution to make it Mix well and finally form a stable and uniform precursor solution. Slowly pour the solution into a 50ml autoclave containing carbon cloth, place it in an oven, and react at 200°C for 16 hours. After the reaction is over, take out the carbon cloth and wash it with deionized water several times. Arrange the carbon to dry at 60℃ to obtain SnO 2 Coated carbon fiber composite material.

[0058] SnO 2 -The carbon fiber membrane material is washed several times ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com