Plant blend oil balanced in nutrients and preparation method of plant blend oil

A nutritionally balanced and oil blending technology, applied in the fields of fat oil/fat refining, food science, edible oil/fat, etc., can solve the problems of imbalance of omega-3 fatty acid ratio and lack of omega-3 fatty acid, and achieve nutritional balance and high content , The effect of easy absorption by the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

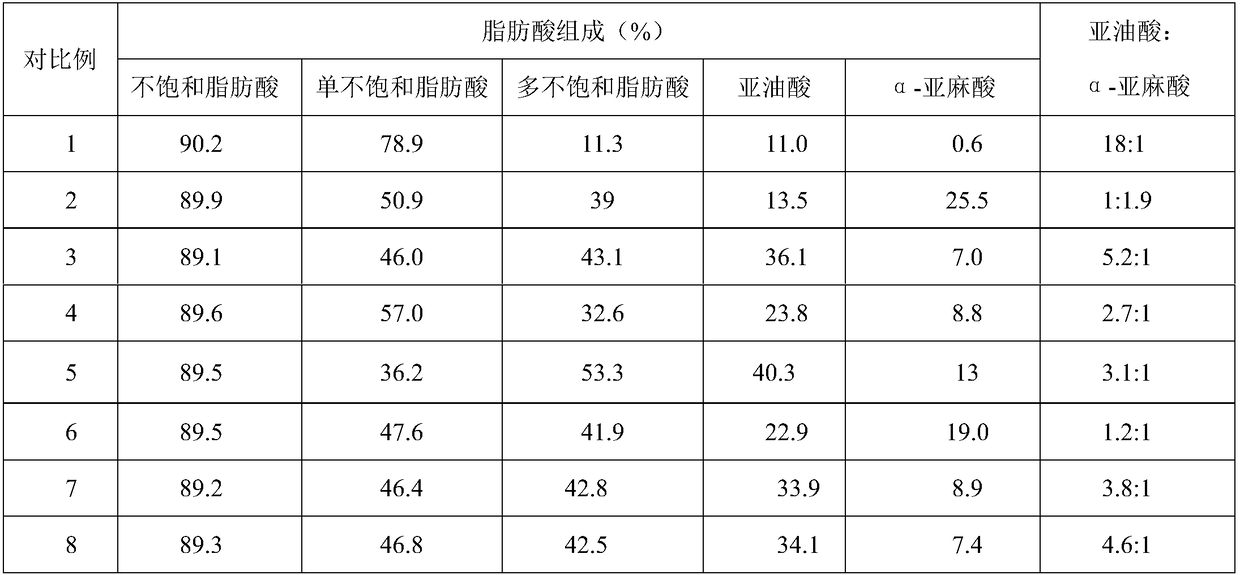

Embodiment 1

[0020] The nutritionally balanced plant blending oil of Example 1 includes the following raw materials in mass proportions: 40% camellia seed, 30% hemp seed, and 30% linseed.

[0021] The preparation method of the nutritionally balanced vegetable blend oil of embodiment 1 is:

[0022] First, weigh the raw materials according to the mass ratio, pulverize them, mix them evenly, and then add them to the multistage separation supercritical CO 2 In the extraction kettle of the extraction equipment, tighten the lid of the extraction kettle, open the CO 2 The gas cylinder, the gas source enters the gas valve, and the extraction process conditions are adjusted. The extraction temperature is 55°C, the extraction pressure is 25MPa, and the extraction is started. The extraction time is 1.0h. After the extraction is completed, the CO in the supercritical state 2 And the mixture will enter the separation tank for decompression separation, adjust the process conditions of each separation t...

Embodiment 2

[0027] The nutritionally balanced plant blending oil of Example 2 includes the following raw materials in mass proportions: 60% camellia seed, 20% hemp seed, and 20% linseed.

[0028] The preparation method of the nutritionally balanced vegetable blend oil of embodiment 2 is:

[0029] First, weigh the raw materials according to the mass ratio, pulverize them, mix them evenly, and then add them to the multistage separation supercritical CO 2 In the extraction kettle of the extraction equipment, tighten the lid of the extraction kettle, open the CO 2 The gas cylinder, the gas source enters the gas valve, and the extraction process conditions are adjusted. The extraction temperature is 50°C, the extraction pressure is 45MPa, and the extraction is started. The extraction time is 4.0h. After the extraction is completed, the CO in the supercritical state 2 And the mixture will enter the separation tank for decompression separation, adjust the process conditions of each separation t...

Embodiment 3

[0033] The nutritionally balanced vegetable blend oil of Example 3 includes the following raw materials in mass proportions: 50% camellia seed, 25% hemp seed, and 25% linseed.

[0034] The preparation method of the nutritionally balanced vegetable blend oil of embodiment 3 is:

[0035] First, weigh the raw materials according to the mass ratio, pulverize them, mix them evenly, and then add them to the multistage separation supercritical CO 2 In the extraction kettle of the extraction equipment, tighten the lid of the extraction kettle, open the CO 2 The gas cylinder, the gas source enters the gas valve, and the extraction process conditions are adjusted. The extraction temperature is 40°C, the extraction pressure is 40MPa, and the extraction is started. The extraction time is 1.5h. After the extraction is completed, the CO in the supercritical state 2And the mixture will enter the separation tank for decompression separation, adjust the process conditions of each separation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com