Efficient clearing method for scale in evaporation tank

An evaporation tank and fouling technology, which is applied to the field of efficient cleaning of fouling in the evaporation tank, can solve the problems of affecting heat exchange efficiency, time-consuming and laborious operation, poor cleaning effect, etc., and achieves the effect of saving manpower, high efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a cleaning method for fouling in the evaporation tank, comprising the steps of:

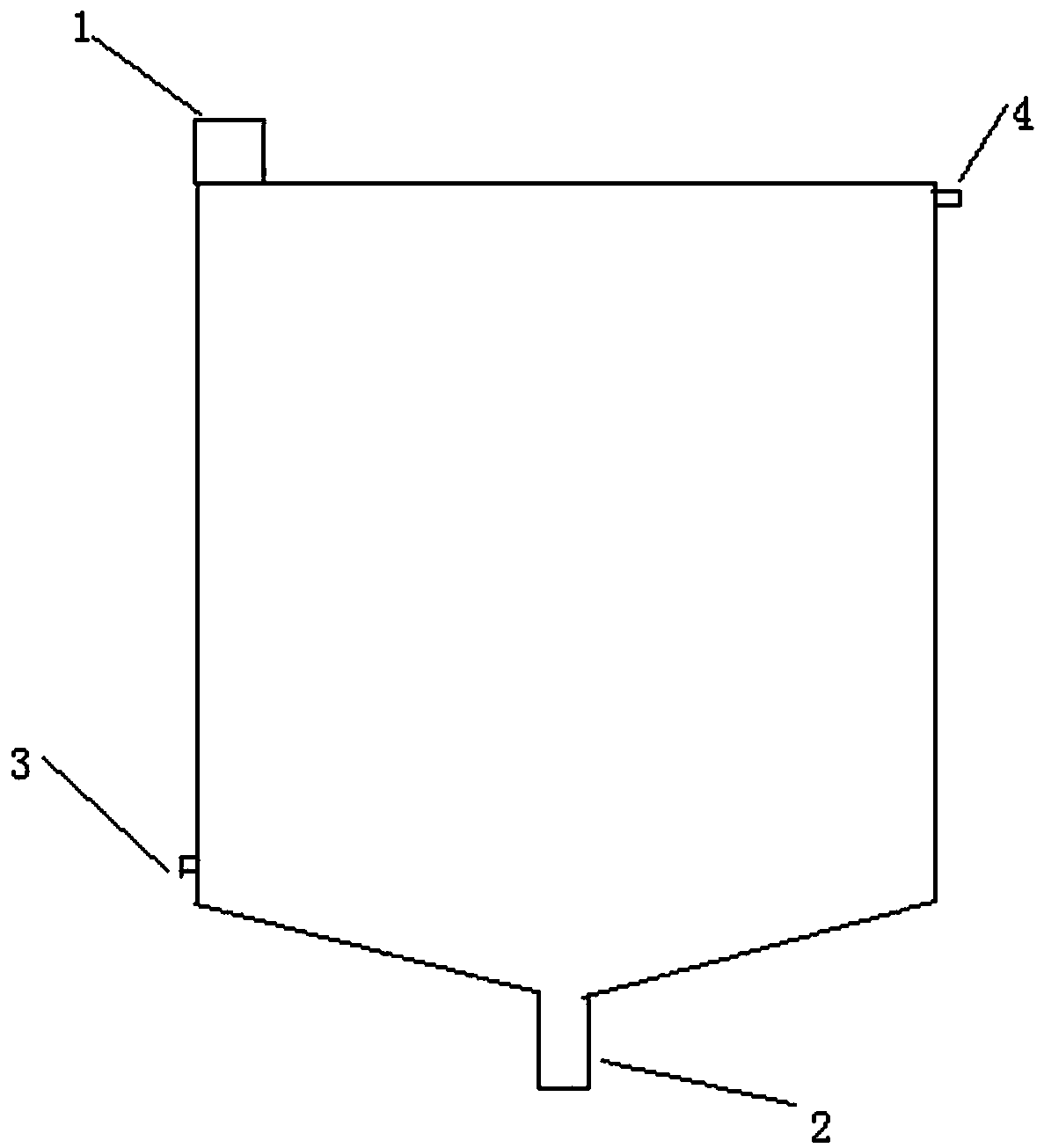

[0029] (1) Residual juice cleaning: Open the water inlet valve 1 and open the drain valve 2 at the same time, put a high-pressure water pipe into the evaporation tank for spray cleaning, and rinse the residual sugar juice in the evaporation tank with clean water for 3 minutes under high pressure. The pressure of high-pressure washing is 50MPa. After the water in the evaporation tank is drained, close the water inlet valve 1 and the drain valve 2;

[0030] (2) First-level descaling:

[0031] a. Open the air inlet 3, and pass into the evaporation tank the high-temperature exhaust gas produced when the boiler in the factory is heating. The tube is heated to 100°C and kept at constant pressure. At this time, the temperature of the evaporator is 100°C, and the pressure of the evaporator is 50MPa;

[0032] b. Repeat the operation of step a above, every 30 minutes, open...

Embodiment 2

[0038] This embodiment provides a cleaning method for fouling in the evaporation tank, comprising the steps of:

[0039] (1) Residual juice cleaning: Open the water inlet valve 1 and open the drain valve 2 at the same time, pass a high-pressure water pipe into the evaporation tank for spray cleaning, and rinse the residual sugar juice in the evaporation tank with clean water for 5 minutes under high pressure. The pressure of high-pressure washing is 120MPa. After the water in the evaporation tank is drained, close the water inlet valve 1 and the drain valve 2;

[0040] (2) First-level descaling:

[0041] a. Open the air inlet 3, and pass into the evaporation tank the high-temperature waste gas produced when the boiler in the factory is heating. The tube is heated to 160°C and kept at constant pressure. At this time, the temperature of the evaporation tank is 100 degrees, and the pressure of the evaporation tank is 100MPa;

[0042] b. Repeat the operation of step a above, every...

Embodiment 3

[0048] This embodiment provides a cleaning method for fouling in the evaporation tank, comprising the steps of:

[0049] (1) Residual juice cleaning: Open the water inlet valve 1 and open the drain valve 2 at the same time, put a high-pressure water pipe into the evaporation tank for spray cleaning, and use clean water to wash the residual sugar juice in the evaporation tank for 3.5 minutes under high pressure. The pressure of high-pressure washing is 70MPa , close the water inlet valve and drain valve after the water in the evaporation tank is drained;

[0050] (2) First-level descaling:

[0051] a. Open the air inlet 3, and pass into the evaporation tank the high-temperature waste gas produced when the boiler in the factory is heating. The tube is heated to 130°C, and the constant pressure is kept warm to ensure that the temperature of the evaporation tank is greater than 100 degrees, and the pressure of the evaporation tank is 70MPa;

[0052] b. Repeat the operation of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com