A modified propanolamine production device and production method thereof

A production method and production device technology, applied in the field of modified propanolamine production devices, can solve problems such as unreasonable energy utilization, achieve the effects of shortening production time, accelerating cooling, and overcoming difficulties in product transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

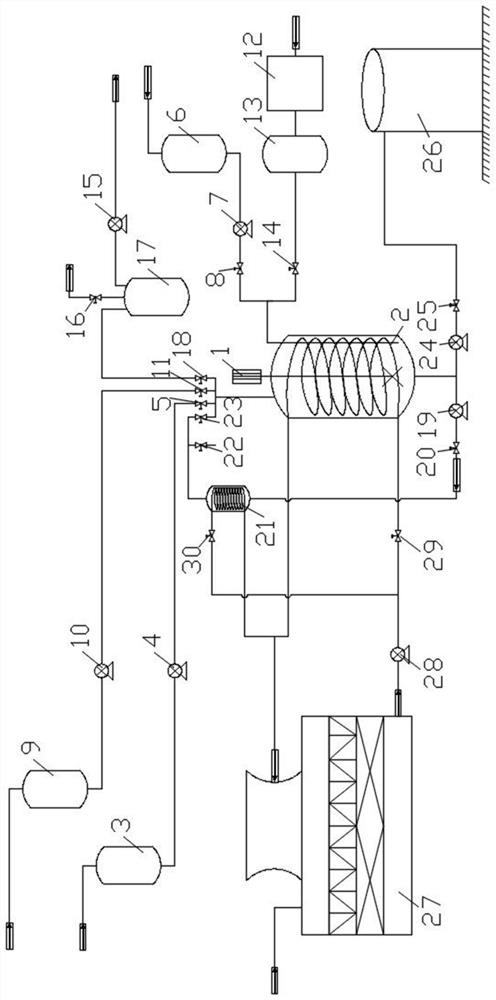

Method used

Image

Examples

Embodiment 1

[0049] Pump 7515kg of monoethanolamine (99.87%) into the reaction kettle 2, start the vacuum pump 15, and pump the pressure in the reaction device to -0.042MPa. Nitrogen (99.9%, the same below) was charged to make the internal pressure of the reaction device reach 0.101 MPa, and the internal pressure of the reaction device was evacuated to -0.042 MPa again. Start mixer 1 and external circulation pump 19, begin to pump into 14461kg propylene oxide (99.99%), treat that the temperature in the device rises to 80 ℃, open circulating cooling water pump 28, adjust the opening degree of the ninth valve 29 and the tenth valve 30 and The pumping flow of propylene oxide controls the temperature in the system to maintain between 80°C and 85°C, and the pressure is less than 0.15MPa. After 213 minutes, the pumping of propylene oxide was completed. At this time, the temperature inside the device was 83°C and the pressure was 0.105MPa. Turn off the circulating cooling water pump 28 when the ...

Embodiment 2

[0051] Pump 7559kg of monoethanolamine (99.87%) into the reaction kettle 2, start the vacuum pump 15, and pump the pressure in the reaction device to -0.058MPa. Nitrogen (99.9%, the same below) was charged to make the pressure inside the reaction device reach 0.107MPa, and the pressure inside the reaction sub-device was evacuated to -0.058MPa again. Start mixer 1 and external circulation pump 19, begin to pump into 14486kg propylene oxide (99.99%), treat that the temperature in the device rises to 85 ℃, open circulating cooling water pump 28, adjust the opening of the ninth valve 29 and the tenth valve 30 and The pumping flow of propylene oxide controls the temperature in the system to maintain between 85°C and 90°C, and the pressure is less than 0.15MPa. After 188 minutes, the pumping of propylene oxide was completed. At this time, the temperature inside the device was 89°C and the pressure was 0.123MPa. Close the circulating cooling water pump 28 when the temperature drops ...

Embodiment 3

[0053] Pump 6655kg of monoethanolamine (99.87%) into the reaction kettle 2, start the vacuum pump 15, and pump the internal pressure of the reaction sub-device to -0.077MPa. Nitrogen (99.9%, the same below) is charged to make the internal pressure of the reaction sub-device reach 0.102MPa, and the internal pressure of the reaction device is evacuated to -0.077MPa again. Start mixer 1 and external circulation pump 19, begin to pump into 14486kg propylene oxide (99.99%), treat that the temperature in the device rises to 90 DEG C, open circulating cooling water pump 28, adjust the opening degree of the ninth valve 29 and the tenth valve 30 and The pumping flow of propylene oxide controls the temperature in the system to maintain between 90°C and 100°C, and the pressure is less than 0.15MPa. After 175 minutes, the pumping of propylene oxide was completed. At this time, the temperature inside the device was 95°C and the pressure was 0.092MPa. Close the circulating cooling water pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com