Microfluid sensing device and method for fabricating the same

A sensing element and microfluidic technology, which is applied in the direction of fluid velocity measurement, electrical components, optical components, etc., can solve the problems of complex process steps and miniaturization of components that do not meet the requirements, so as to simplify process steps, reduce manual operation costs, reduce The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

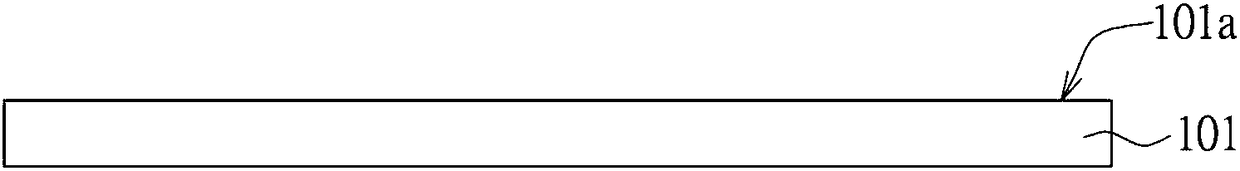

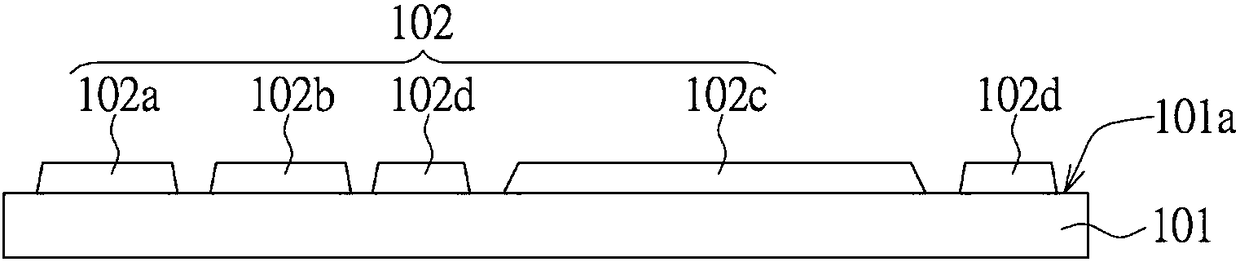

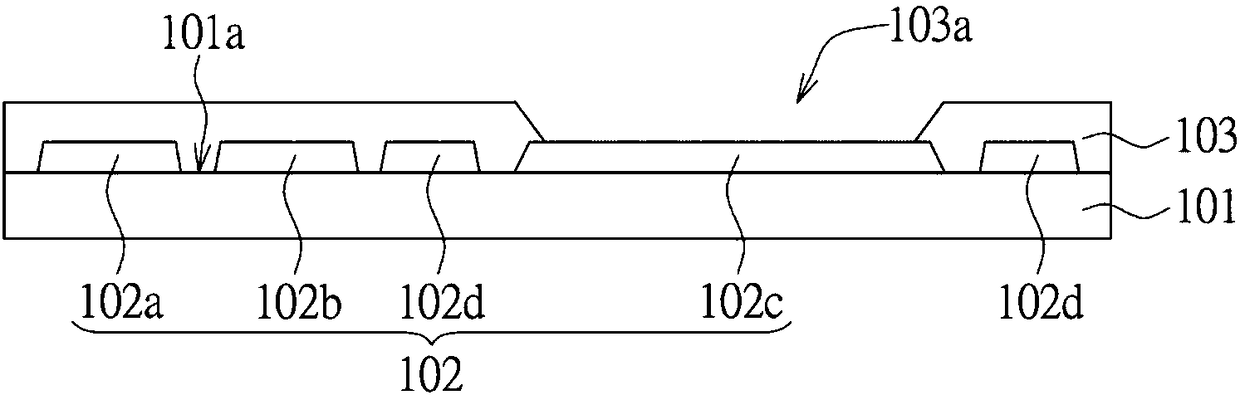

[0036] This specification provides a method for fabricating a microfluidic sensing element, which can simplify the process steps of the microfluidic sensing element and greatly reduce the size of the microfluidic sensing element. In order to make the above-mentioned embodiments and other objects, features and advantages of the present specification more obvious and easy to understand, several preferred embodiments are listed below and described in detail with the accompanying drawings.

[0037] However, it must be noted that these specific implementation cases and methods are not intended to limit the present invention. The present invention may still be practiced with other features, components, methods and parameters. The preferred embodiments are provided only to illustrate the technical features of the present invention, and not to limit the claims of the present invention. Those with ordinary knowledge in the technical field will be able to make equivalent modifications ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com