Approximate-junction microflow embedded high-efficient GaN transistor and manufacturing method thereof

A transistor and gallium nitride technology, applied in electrical solid state devices, semiconductor devices, semiconductor/solid state device components, etc., can solve the problems of device performance and reliability degradation, limiting gallium nitride device performance, and device junction temperature rise. , to achieve the effect of increasing the maximum output power, improving the efficient heat dissipation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

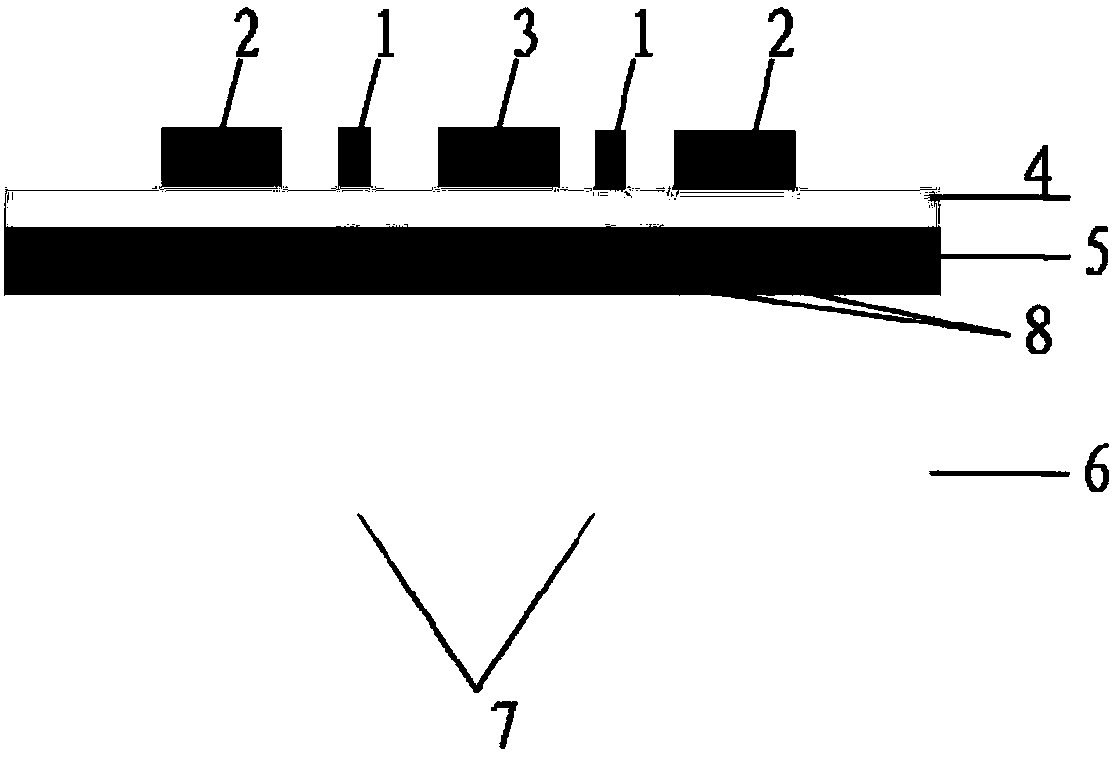

[0037] A method for manufacturing a near-junction microflow embedded gallium nitride transistor with high efficiency heat dissipation, specifically comprising the following steps:

[0038] 1) Complete the conventional front-side process of gallium nitride transistors to obtain gallium nitride transistors, the substrate of which is made of SiC material, the gate-to-gate spacing of the active region is 30um, and it is a 10-gate structure;

[0039] 2) Preparation of embedded micro-channels in the near-junction region;

[0040] ①According to the size of the active area of the completed GaN transistor, the size of the microfluidic channel in the near-junction area is designed to be 20um, and its center is consistent with the center of the heat source. The distribution is based on the size of the active area to be 10 groups, which fully meets its heat dissipation capacity and reliability capability.

[0041] ② Coating a silicon oxide dielectric protective layer on the front of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com