Anti-tearing steel wire rope core conveying belt

A steel cord core and anti-tear technology, which is applied in the field of conveyor belts, can solve the problems affecting the grooving and flex resistance of steel cord conveyor belts, increasing the thickness and self-weight of conveyor belts, and poor scratch and tear resistance. , to achieve the effect of enhancing rigidity and tear resistance, improving quality and preventing tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

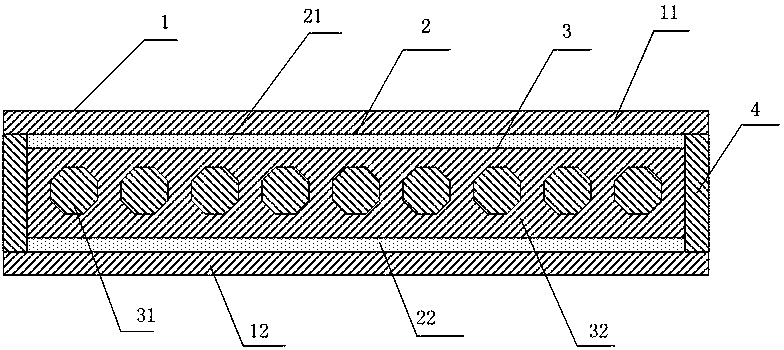

[0022] A tear-resistant steel cord conveyor belt, such as figure 1 , including a cover layer 1, a tear-resistant layer 2, an intermediate layer 3 and an edge rubber layer 4; the intermediate layer 3 is arranged in the middle of the conveyor belt, and includes a steel wire rope 31 and an adhesive glue 32, and the adhesive glue 32 wraps the steel wire rope 31; Anti-tear layer 2 comprises upper anti-tear layer 21 and lower anti-tear layer 22, and upper anti-tear layer 21 is on the top of intermediate layer 3, and lower anti-tear layer 22 is below intermediate layer 3, and anti-tear layer 2 is dipped fiber cloth, dipped fiber cloth is made of fiber cloth impregnated with covering rubber glue, fiber cloth is woven from polyester yarn as warp and weft, the addition of dipped fiber cloth increases the safety of the steel cord conveyor belt The transverse tensile strength can effectively prevent the occurrence of tearing of the steel cord conveyor belt. The impregnated fiber cloth is ...

Embodiment 2

[0025] A tear-resistant steel cord conveyor belt, comprising a cover layer 1, a tear-resistant layer 2, an intermediate layer 3 and an edge rubber layer 4; the intermediate layer 3 is arranged in the middle of the conveyor belt, including a steel wire rope 31 and an adhesive glue 32, Adhesive glue 32 wraps steel wire rope 31; Anti-tear layer 2 comprises upper anti-tear layer 21 and lower anti-tear layer 22, and upper anti-tear layer 21 is on the top of middle layer 3, and lower anti-tear layer 22 is in the middle Under the layer 3, the anti-tearing layer 2 is dipped fiber cloth, which is made of fiber cloth impregnated with covering rubber glue. Added to increase the transverse tensile strength of the steel cord conveyor belt, which can effectively prevent the occurrence of tearing of the steel cord conveyor belt. The thickness of the impregnated fiber cloth is small and light, and will not affect the steel cord conveyor belt due to the increase in thickness and weight. Groova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com