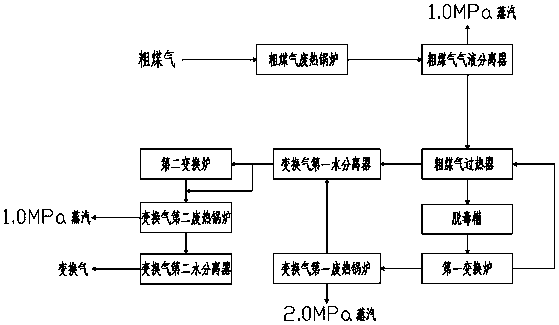

Coarse coal gas conversion process

A crude gas and process technology, applied in the field of coal chemical industry, can solve the problems of high energy consumption, difficult to control the depth of the shift reaction, and low energy efficiency of the shift process, and achieve the effects of reducing energy consumption, protecting from poisoning, and flexibly controlling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

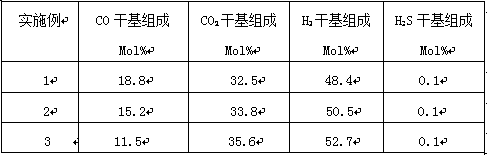

Embodiment 1

[0019] A crude gas shift process, comprising the following processes:

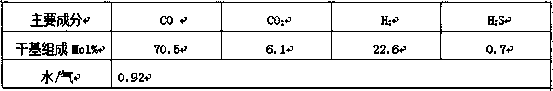

[0020] The saturated crude gas from the coal gasification device, the specifications and parameters are shown in Table 1. First, it enters the crude gas waste heat boiler to produce 1.0Mpa steam. After cooling down, it enters the crude gas gas-liquid separator for gas-liquid separation, and the ash, etc. Impurities are removed, and the water / gas volume ratio of the crude gas is adjusted to 0.3 at the same time, and then enters the crude gas superheater to be heated to 230°C and then enters the detoxification tank to remove Cl - , As, dust and other impurities, avoid Cl - , As, dust and other impurities poison the shift catalyst, and then enter the first shift furnace for preliminary shift reaction. The shift reaction uses CO sulfur-resistant shift reaction catalyst with a space velocity of 8000h -1 , the bed temperature is 450°C, the shifted shift gas is divided into two paths and enters the shift gas fir...

Embodiment 2

[0022] A crude gas shift process, comprising the following processes:

[0023] The saturated crude gas from the coal gasification device, the specifications and parameters are shown in Table 1. First, it enters the crude gas waste heat boiler to produce 1.0Mpa steam. After cooling down, it enters the crude gas gas-liquid separator for gas-liquid separation, and the ash, etc. Impurities are removed, and the water / gas volume ratio of the crude gas is adjusted to 0.5 at the same time, and then enters the crude gas superheater to be heated to 210°C and then enters the detoxification tank to remove Cl - , As, dust and other impurities, avoid Cl - , As, dust and other impurities poison the shift catalyst, and then enter the first shift furnace for preliminary shift reaction. The shift reaction uses CO sulfur-resistant shift reaction catalyst with a space velocity of 6000h -1 , the bed temperature is 420°C, the shifted shift gas is divided into two paths and enters the shift gas fir...

Embodiment 3

[0025] A crude gas shift process, comprising the following processes:

[0026] The saturated crude gas from the coal gasification device, the specifications and parameters are shown in Table 1. First, it enters the crude gas waste heat boiler to produce 1.0Mpa steam. After cooling down, it enters the crude gas gas-liquid separator for gas-liquid separation, and the ash, etc. Impurities are removed, and the water / gas volume ratio of the crude gas is adjusted to 0.8 at the same time, and then enters the crude gas superheater to be heated to 230°C and then enters the detoxification tank to remove Cl - , As, dust and other impurities, avoid Cl - , As, dust and other impurities poison the shift catalyst, and then enter the first shift furnace for preliminary shift reaction. The shift reaction uses CO sulfur-resistant shift reaction catalyst with a space velocity of 6000h -1 , the bed temperature is 450°C, the shifted shift gas is divided into two paths and enters the shift gas fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com