High pressure disc tube type nanofiltration membrane salt separation system

A nanofiltration membrane and disc type technology is applied in the field of high-pressure disc type nanofiltration membrane salt separation system, which can solve the problems of low operating pressure, inability to be practical, and inability to increase the concentration ratio, so as to reduce the generation of hazardous waste and promote The effect of recycling and relieving tie rod fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

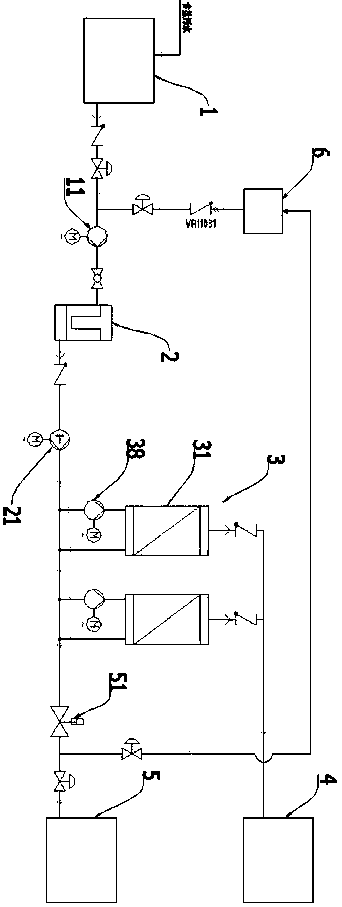

[0032] Such as figure 1 As shown, the present embodiment provides a high-pressure disc-tube nanofiltration membrane salt separation system, which includes a sewage storage tank 1 , a pre-filter 2 and a module 3 connected in sequence. The module 3 is also connected with a filtrate storage tank 4 and a concentrated solution storage tank 5, which are respectively used to store the filtrate and the concentrated solution obtained after being processed by the module 3. A cleaning device is also connected between the module 3 and the concentrated liquid storage tank 5 for cleaning the module 3 .

[0033] The sewage storage tank 1 is used to store the collected high-salt concentrate, and a water inlet pump 11 is arranged between the sewage storage tank 1 and the pre-filter 2 . At least one set of pre-filters 2 is provided, and the filter diameter of the pre-filters 2 is 10 microns to filter out impurities larger than 10 microns to ensure the water quality of the water entering the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com