Full-automatic numerical control double-head milling machine

A double-head milling machine, fully automatic technology, applied in milling machines, milling machine equipment, metal processing equipment and other directions, can solve the problems of random errors in measurement and positioning, the degree of automation of equipment is not high, and the milling machine does not have chamfering function, etc., to reduce intermediate Links, improvement of work efficiency, technical solutions and clear effects of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

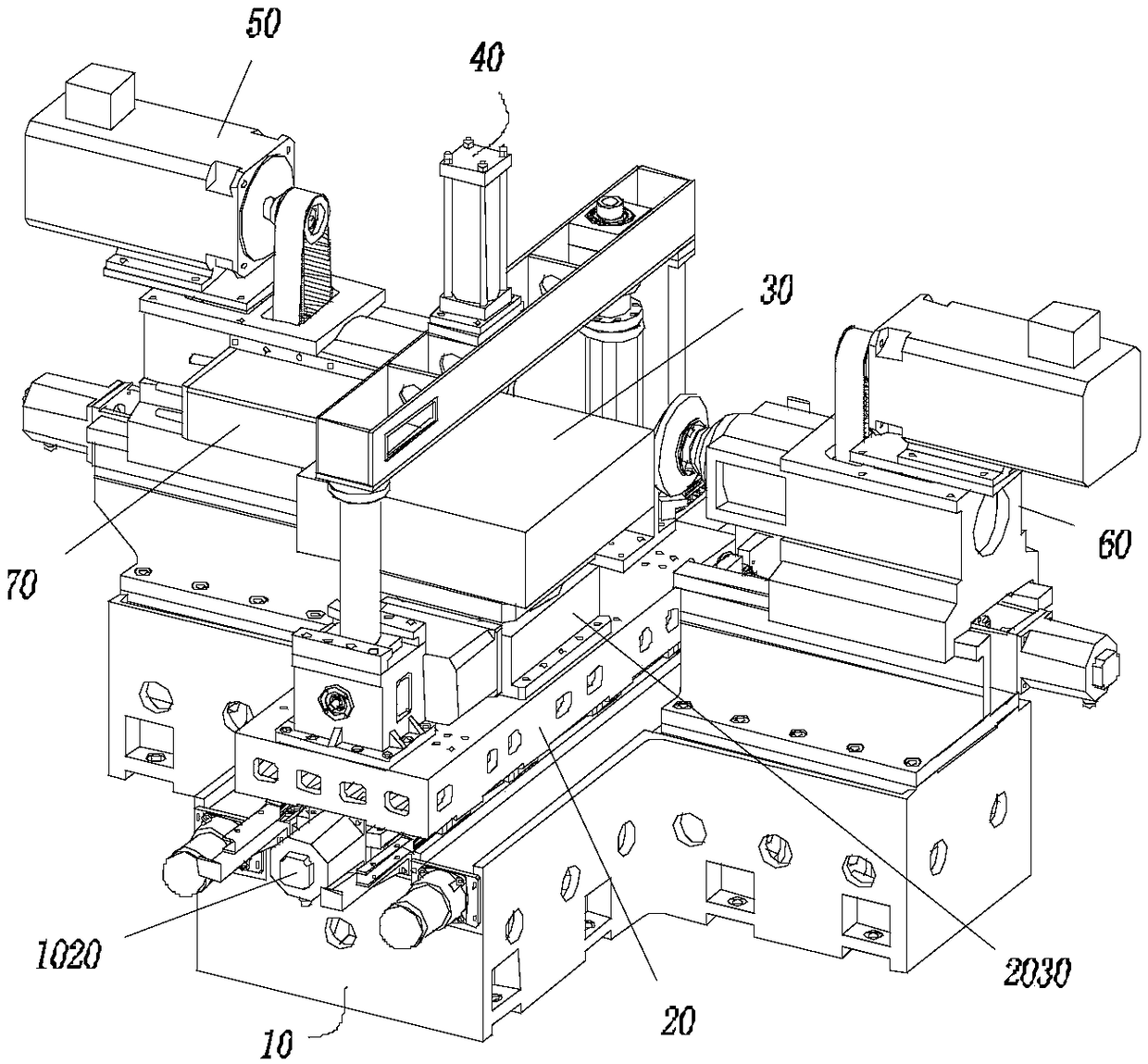

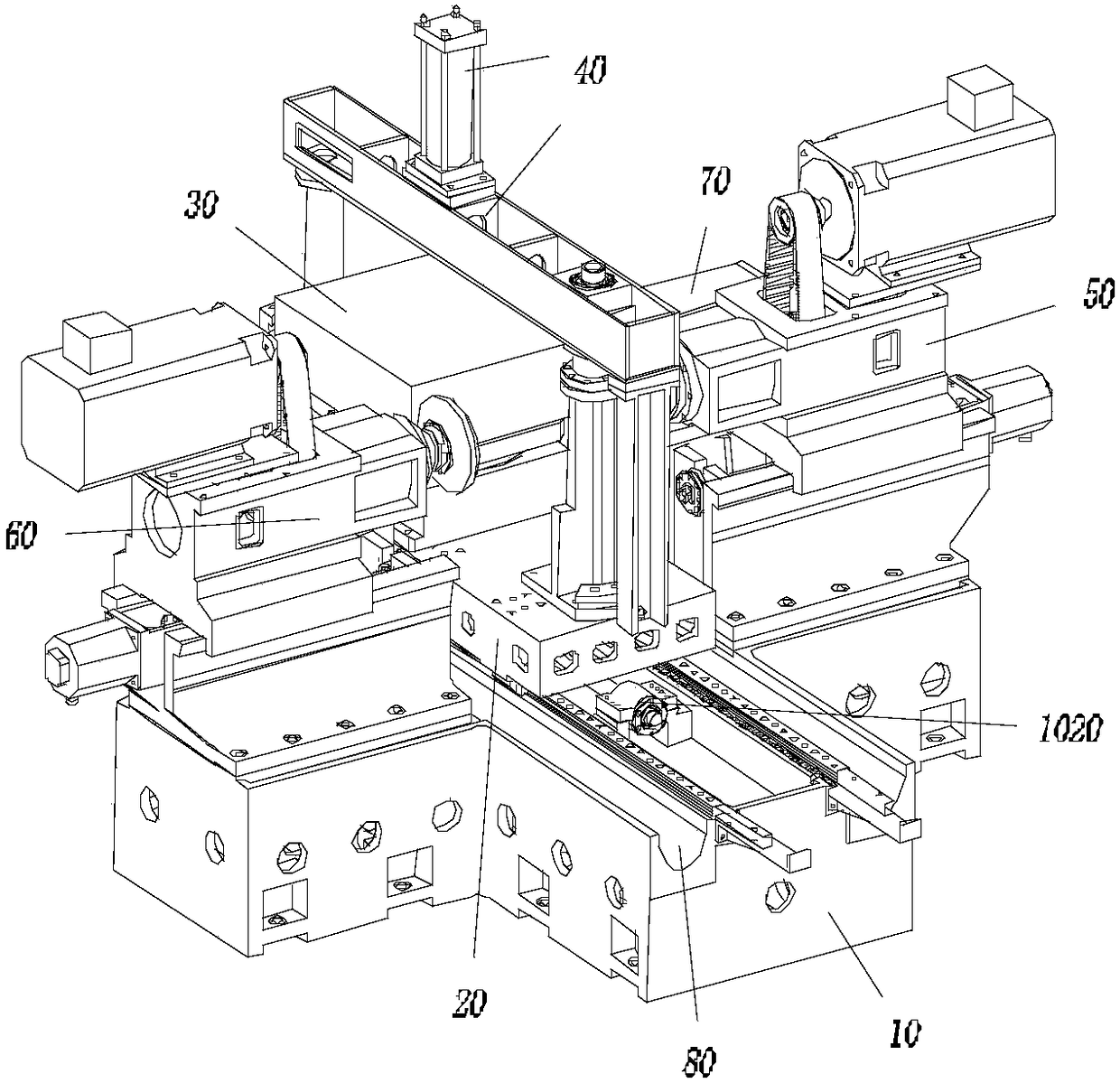

[0028] see figure 1 , the fully automatic CNC double-head milling machine provided by the application includes a fixed seat 10, a sliding seat 20, a rotary table 30, a pressing mechanism 40, a first station 50, a second station 60, an automatic positioning device 70, and an automatic measuring device (not shown in the figure) and milling machine digital control system (not shown in the figure).

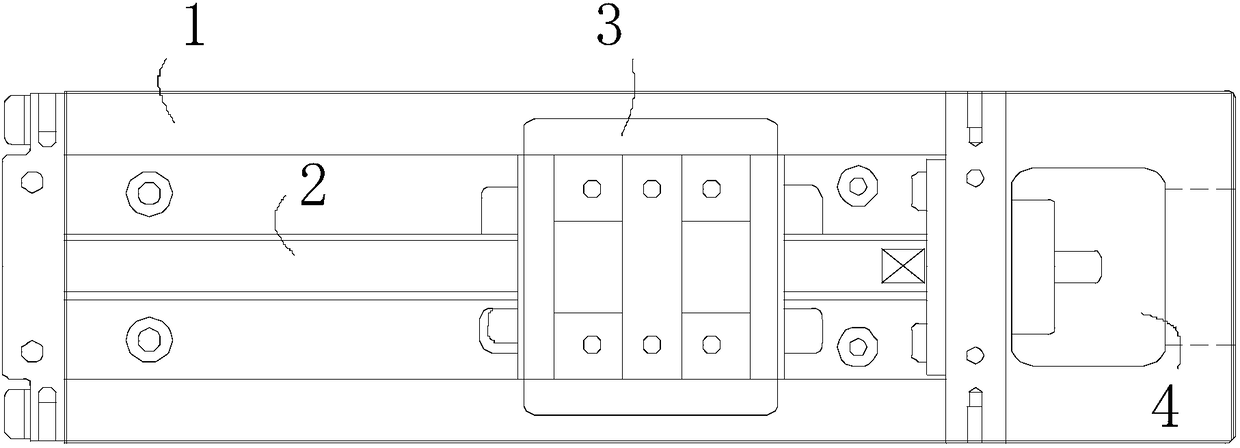

[0029] The fixed seat 10 is installed on the infrastructure such as the workshop floor in this embodiment, and the sliding seat 20 is slidably connected to the fixed seat 10 through the screw slide module 1020; driven by the digital control system, the sliding seat 20 can move along the The fixed seat 10 advances or retreats. The lead screw slide module 1020 can be any existing product on the market, as long as the power and specifications match, the technical solution of the present invention can be realized and the expected technical effect can be achieved. In general, the lead sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com