Tooth punching cutter for tooth punching of heat insulating aluminum profile by adopting casting process

An aluminum profile and tool technology, which is applied in the field of heat-insulating aluminum profile gear cutting tools, can solve the problems of low bonding strength, large mechanical vibration, affecting the mechanical properties and quality of heat-insulating aluminum profiles, etc., and achieves bonding strength and shearing. High strength, simple and easy equipment structure, and the effect of saving equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

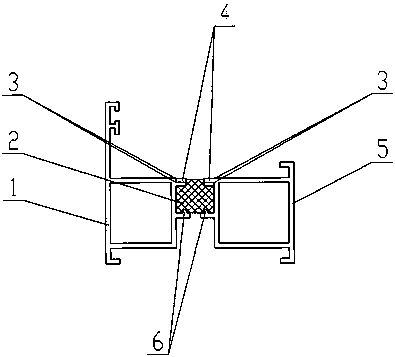

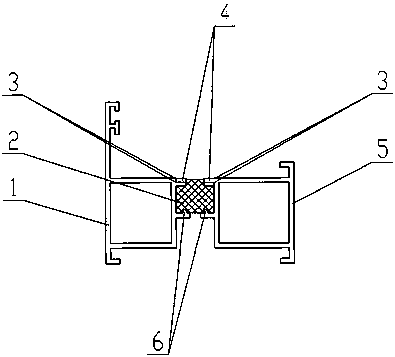

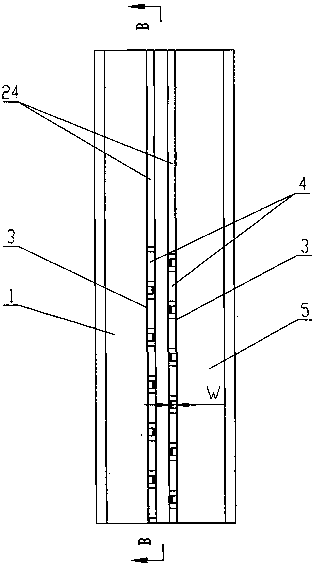

[0017] Specific implementation mode one: as Figure 1-8 As shown, the cast-indented heat-insulating aluminum profile is composed of a left aluminum profile 1, a polyurethane strip 2 and a right aluminum profile 5, the polyurethane strip 2 is arranged longitudinally along the aluminum profile, and the left aluminum profile 1 passes through the polyurethane strip 2 and the right aluminum profile 5 are connected together, and the polyurethane strip 2 fills the inside of the pouring notch 8; the cast-indented heat-insulating aluminum profile also includes two protruding locking points 6 arranged longitudinally along the aluminum profile, And two rows of rolling locking points 4 arranged longitudinally along the aluminum profile, the raised locking point 6 is located above the connecting strip 7 connecting the left aluminum profile 1 and the right aluminum profile 5, that is, at the bottom of the pouring notch 8, The rolling locking points 4 are respectively located on the upper si...

specific Embodiment approach 2

[0019] Specific implementation mode two: as Figure 1-10 As shown, in the casting method for toothing and heat-insulating aluminum profile toothing cutter, the guide roller 27 is used to replace the guide disc 19 ( Figure 6 , 7 . The raised locking point 6 forms a plurality of extrusion grooves 29 arranged longitudinally along the profile ( Figure 10 ), the spacing b=5-30mm between the extrusion grooves 29, the rolling disc 20 continuously rotates and rolls the two protruding strips 24 above the pouring notch 8, and the tooth tips of the left and right two rolling discs 20 A14 Roll the triangular groove or rectangular groove 3 of the left aluminum profile 1 and the right aluminum profile 5, and the left and right two raised strips 24 are on the tooth tip A14 of the rolling disc 20 and the triangular groove or rectangular groove The 3 parts are disconnected at the same time to form the rolling locking point 4, and the rolling disc 20 drives the aluminum profile 9 to be for...

specific Embodiment approach 3

[0020] Specific implementation mode three: as Figure 1-11 As shown, in the casting method for toothing and heat-insulating aluminum profile toothing cutter, the guide roller 27 is used to replace the guide disc 19 ( Figure 6 , 7 . The protruding locking point 6 forms a plurality of extrusion grooves 29 arranged longitudinally along the aluminum profile ( Figure 11 ), the spacing b=5-30mm between the extrusion grooves 29 reduces the diameter of the rolling disc 20, and the tooth tip A14 of the rolling disc 20 does not contact the protruding strip 24 above the casting groove 8 of the aluminum profile, No rolling locking point 4 is formed, and the aluminum profile pouring notch 8 is still provided with raised strips 24 . Other compositions and connections are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com