Method for synthesizing silicon-rich ZSM-48 zeolite molecular sieve by using seed-crystal guiding method

A technology of ZSM-48 and zeolite molecular sieve, which is applied to molecular sieve catalysts, molecular sieves and alkali exchange compounds, chemical instruments and methods, etc., can solve the problems of high toxicity, high cost, and environmental pollution, and achieve high yield, low price, The effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the synthesis of all silicon ZSM-48 zeolite molecular sieve

[0018] First, 1.56g of solid silica gel, 0.51g of Na 2 SiO 3 9H 2 O, 0.1g of all-silicon ZSM-48 zeolite seed crystals (6%) and 1.9g of ethanol were placed in a mortar and ground for 2min, then the reaction materials were added into a polytetrafluoroethylene stainless steel reactor, and crystallized at 180°C for 1d to complete crystallization The product was filtered with suction and dried to obtain the product. The molar ratio of the reaction raw materials is as follows: SiO 2 :Na 2 O:C 2 h 5 OH=1:0.07:1.5.

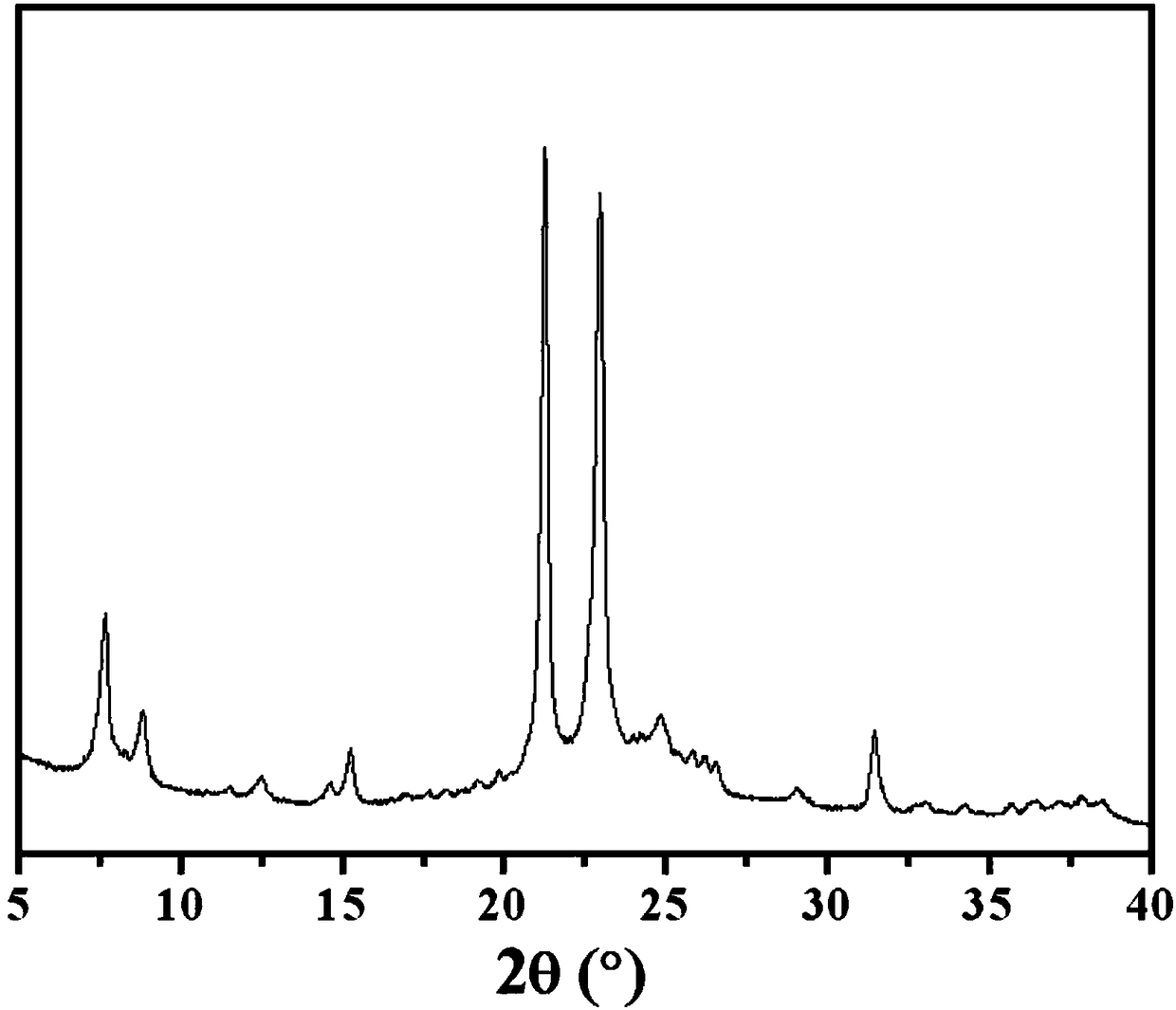

[0019] Its structure is ZSM-48 zeolite molecular sieve by X-ray diffraction analysis. figure 1 , and it can be seen from the scanning electron microscope that the synthesized product is rod-shaped, which is a typical morphology of ZSM-48 zeolite molecular sieve. figure 2 Scanning electron micrograph (SEM) of the synthesized product.

Embodiment 2

[0020] Embodiment 2: High-temperature synthesis of all-silicon ZSM-48 zeolite molecular sieve

[0021] First, 1.6g solid silica gel, 0.09g NaOH, 0.16g all-silicon ZSM-48 zeolite seed crystal (10%) and 0.44g ethanol were placed in a mortar and ground for 2min, and then the reaction materials were added to a polytetrafluoroethylene stainless steel reactor During the crystallization at 200°C for 8 hours, the crystallization was complete, and the product was filtered with suction and dried to obtain the product. The molar ratio of the reaction raw materials is as follows: SiO 2 :Na 2 O:C 2 h 5 OH=1:0.04:0.5.

Embodiment 3

[0022] Embodiment 3: Low-temperature synthesis of all-silicon ZSM-48 zeolite molecular sieve

[0023] First, put 1.6g of solid silica gel, 0.31g of NaOH, 0.016g of all-silicon ZSM-48 zeolite seed crystals (1%) and 3.5g of ethanol in a mortar and grind for 2min, then add the reaction materials into a polytetrafluoroethylene stainless steel reactor In the process, crystallization at 80°C for 10 days was complete crystallization, and the product was filtered with suction and dried to obtain the product. The molar ratio of the reaction raw materials is as follows: SiO 2 :Na 2 O:C 2 h 5 OH=1:0.15:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com