Domestic stainless steel surface degreasing reagent and preparation method thereof

A stainless steel and grease technology, applied in the field of metal surface degreasing, can solve the problems of reagent contamination of clean locations, accelerated stainless steel corrosion, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

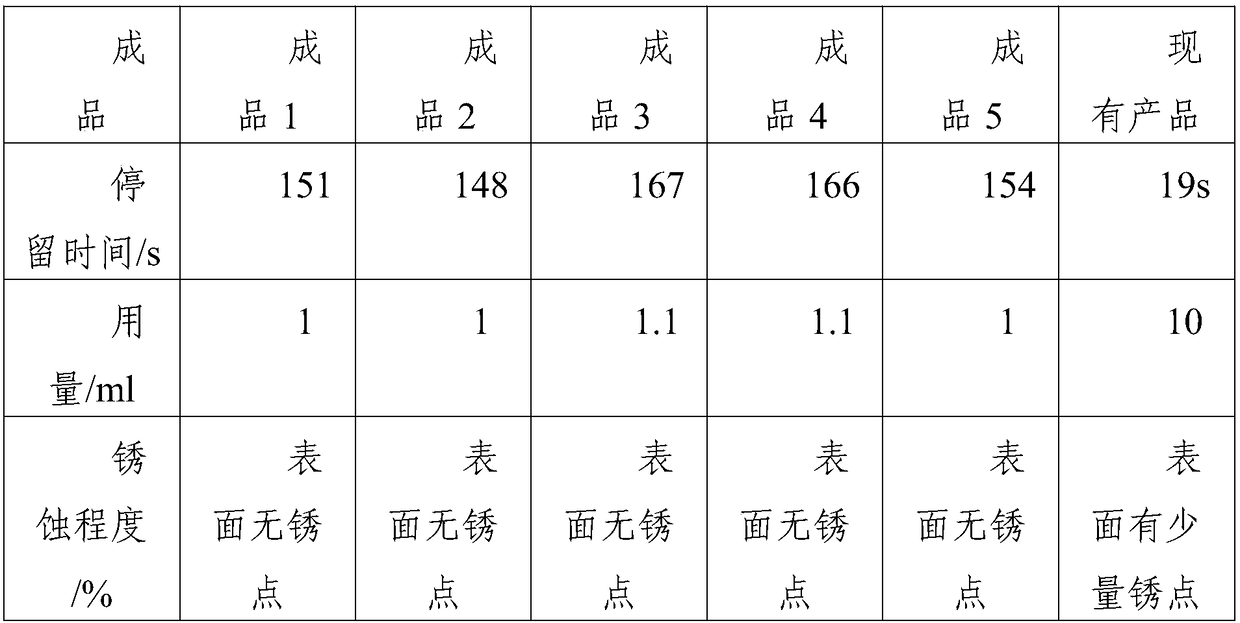

Examples

Embodiment 1

[0021] The invention provides a stainless steel surface degreasing agent for household use and a preparation method thereof, which is prepared from the following raw materials in parts by weight: 5 parts of sodium tert-butoxide, 5 parts of sodium stearate, 5 parts of sodium acetate, 5 parts of Betaine, 5 parts of sodium monohydrogen phosphate, 5 parts of DBU, 5 parts of surfactant, 30 parts of ethanol, 35 parts of distilled water, 1 part of essence and 1 part of vegetarian meat powder, its preparation method comprises the following steps:

[0022] (1) First, take the raw material components by weight parts, pour sodium monohydrogen phosphate into distilled water at normal temperature, stir and dissolve at normal temperature, and obtain solution A;

[0023] (2) Heat the ethanol, keep the temperature at 60°C, pour the sodium stearate powder into the ethanol, stir with a mixer, the stirring speed: 500r / min, and the stirring time: 10min, to obtain solution B;

[0024] (3) Cool sol...

Embodiment 2

[0028] The invention provides a stainless steel surface degreasing agent for household use and a preparation method thereof, which is prepared from the following raw materials in parts by weight: 10 parts of sodium tert-butoxide, 10 parts of sodium stearate, 10 parts of sodium acetate, 10 parts of Betaine, 10 parts of sodium monohydrogen phosphate, 10 parts of DBU, 15 parts of surfactant, 40 parts of ethanol, 40 parts of distilled water, 1 part of essence and 1 part of vegetarian meat powder, its preparation method comprises the following steps:

[0029] (1) First, take the raw material components by weight parts, pour sodium monohydrogen phosphate into distilled water at normal temperature, stir and dissolve at normal temperature, and obtain solution A;

[0030] (2) Heat the ethanol, keep the temperature at 70°C, pour the sodium stearate powder into the ethanol, stir with a blender, the stirring speed: 700r / min, and the stirring time: 15min, to obtain solution B;

[0031] (3)...

Embodiment 3

[0035] The invention provides a stainless steel surface degreasing agent for household use and a preparation method thereof, which is prepared from the following raw materials in parts by weight: 7 parts of sodium tert-butoxide, 7 parts of sodium stearate, 7 parts of sodium acetate, 7 parts Betaine, 7 parts of sodium monohydrogen phosphate, 7 parts of DBU, 10 parts of surfactant, 30 parts of ethanol, 35 parts of distilled water, 1 part of essence and 1 part of vegetarian meat powder, its preparation method comprises the following steps:

[0036] (1) First, take the raw material components by weight parts, pour sodium monohydrogen phosphate into distilled water at normal temperature, stir and dissolve at normal temperature, and obtain solution A;

[0037] (2) Heating ethanol, keeping the temperature at 65°C, pouring sodium stearate powder into ethanol, stirring with a blender, stirring speed: 600r / min, stirring time: 12min, to obtain solution B;

[0038] (3) Cool solution B to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com