Construction process of rubber powder modified asphalt pavement

A technology of modified asphalt and construction technology, applied in the field of modified asphalt, can solve problems such as incapable of high-quality application, and achieve the effects of promoting sustainable development, saving asphalt resources, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

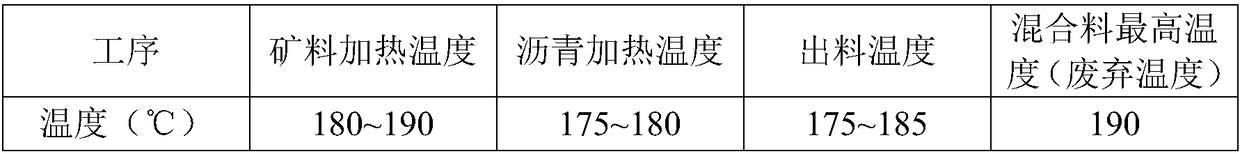

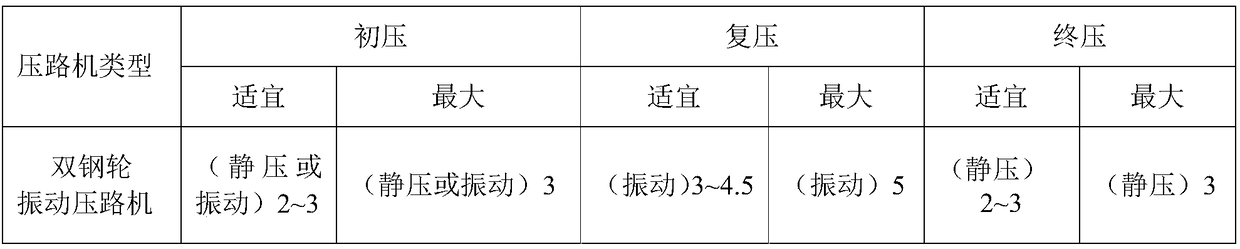

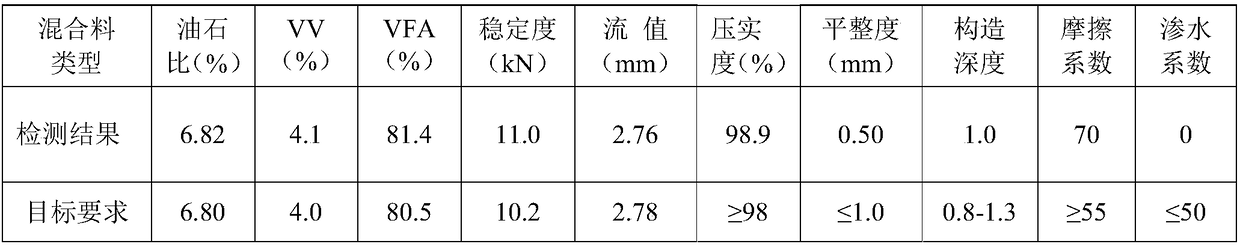

[0037] Step 1, the preparation of rubber powder modified asphalt mixture, including preparation of rubber powder modified asphalt, selection and processing of coarse aggregate and fine aggregate, mixture production and mixing, the specific process is as follows:

[0038] 1) Preparation of rubber powder modified asphalt: drying the rubber powder with a particle size of 40-60 mesh at a drying temperature of 105-115°C; dehydrating the base asphalt for later use; heating the dehydrated base asphalt to 180-190°C ;

[0039] Add the above-mentioned dried rubber powder to the base asphalt process according to the mass percentage, and add it while stirring with a screw agitator to prevent splashing and hurting people during the mixing process; use a mixer to stir, and the stirring speed is from slow to fast , start stirring at 260-300r / min, increase the stirring speed to 1000r / min within 20 minutes, and finally stabilize at 1000r / min and stir for 10-15min. liquid.

[0040] Pump the m...

Embodiment 1

[0123] The preparation of rubber powder modified asphalt in the present invention comprises the following steps:

[0124] 1) Processing of raw materials: drying the rubber powder at a temperature of 105°C; dehydrating the base asphalt for later use;

[0125] 2) Miscibility reaction: heat the dehydrated base asphalt in step 1) to 180°C, then add the dried rubber powder in step 1) into the base asphalt, stir and swell for 42 minutes to obtain a mixed solution; mix the rubber powder When adding to the base asphalt, it must be added while stirring to prevent splashing and hurting people during the stirring process; when starting the mixer to stir, the stirring speed should be slow to fast, starting from 260-300r / min and stirring within 20 minutes The speed was increased to 1000r / min, and finally stabilized at 1000r / min and stirred for 10-15min, and the stirring temperature was controlled at 190°C to 210°C.

[0126] 3) Finished product: pump the mixed liquid in step 2) into the co...

Embodiment 2

[0129] The preparation of rubber powder modified asphalt in the present invention comprises the following steps:

[0130] 1) Processing raw materials: drying the rubber powder at a temperature of 115°C; dehydrating the base asphalt for later use;

[0131] 2) Miscibility reaction: heat the dehydrated base asphalt in step 1) to 185°C, then add the dried rubber powder in step 1) into the base asphalt, stir and swell for 45 minutes to obtain a mixed solution; mix the rubber powder When adding to the base asphalt, it must be added while stirring to prevent splashing and hurting people during the stirring process; when starting the mixer to stir, the stirring speed should be slow to fast, starting from 260-300r / min and stirring within 20 minutes The speed was increased to 1000r / min, and finally stabilized at 1000r / min and stirred for 10-15min, and the stirring temperature was controlled at 190°C to 210°C.

[0132] 3) Finished product: pump the mixed liquid in step 2) into the collo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com