High-strength PE pipe and production method thereof

A processing method and high-strength technology, applied in electrical components and other directions, can solve the problems that the pipe is difficult to adapt to high-strength operation requirements, cannot bear heavy pressure, and has a short service life, so as to shorten the drying and solidification time and avoid being scratched. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high-strength PE pipe, such as Figure 7 As shown, there are PE layer 11, resin layer 12, inner glass fiber layer 13, quartz sand layer 14 and outer glass fiber layer 15 from inside to outside; the glass fiber layer is formed by winding glass fibers on the outer wall of the pipe, The glass fiber is currently soaked in resin before winding, so that a resin layer 12 can be formed between the PE layer 11 and the inner glass fiber layer 13 after winding; the quartz sand layer 14 is wound through the outer glass fiber layer 15 and coated quartz sand; the PE layer 11 includes the following components in parts by weight: 15 parts of polyethylene, 10 parts of binary ethylene propylene rubber, 10 parts of polypropylene fiber, 6 parts of diatomaceous earth, 3 parts of quartz sand 2 parts of FRP, 2 parts of activated carbon, 5 parts of PE resin, 3 parts of polyacrylate, 3 parts of bentonite, 2 parts of antioxidant, 2 parts of plasticizer, and 1 part of defoamer.

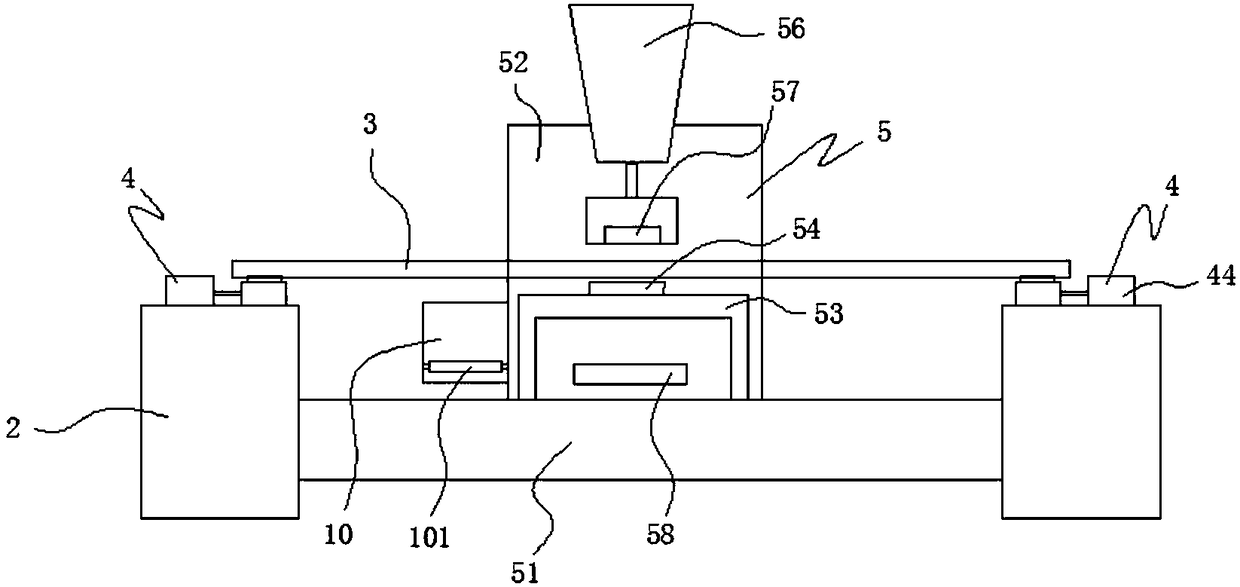

[0036] A proc...

Embodiment 2

[0047] A high-strength PE pipe, such as Figure 7As shown, there are PE layer 11, resin layer 12, inner glass fiber layer 13, quartz sand layer 14 and outer glass fiber layer 15 from inside to outside; the glass fiber layer is formed by winding glass fibers on the outer wall of the pipe, The glass fiber is currently soaked in resin before winding, so that a resin layer 12 can be formed between the PE layer 11 and the inner glass fiber layer 13 after winding; the quartz sand layer 14 is wound through the outer glass fiber layer 15 and coated quartz sand; the PE layer 11 includes the following components in parts by weight: 20 parts of polyethylene, 15 parts of binary ethylene propylene rubber, 12 parts of polypropylene fiber, 8 parts of diatomaceous earth, 5 parts of quartz sand 3 parts of FRP, 3 parts of activated carbon, 8 parts of PE resin, 5 parts of polyacrylate, 5 parts of bentonite, 3 parts of antioxidant, 3 parts of plasticizer, and 2 parts of defoamer.

[0048] A proc...

Embodiment 3

[0051] A high-strength PE pipe, such as Figure 7 As shown, there are PE layer 11, resin layer 12, inner glass fiber layer 13, quartz sand layer 14 and outer glass fiber layer 15 from inside to outside; the glass fiber layer is formed by winding glass fibers on the outer wall of the pipe, The glass fiber is currently soaked in resin before winding, so that a resin layer 12 can be formed between the PE layer 11 and the inner glass fiber layer 13 after winding; the quartz sand layer 14 is wound through the outer glass fiber layer 15 and coated quartz sand; the PE layer 11 includes the following components in parts by weight: 20 parts of polyethylene, 10 parts of binary ethylene propylene rubber, 12 parts of polypropylene fiber, 6 parts of diatomaceous earth, 5 parts of quartz sand 3 parts, 3 parts of FRP, 3 parts of activated carbon, 5 parts of PE resin, 3 parts of polyacrylate, 3 parts of bentonite, 3 parts of antioxidant, 2 parts of plasticizer, and 2 parts of defoamer.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com