Technical processing of Saccharomyces cerevisiae for food processing to realize direct edibility of protein of Saccharomyces cerevisiae

A technology for edible yeast and food processing, which is applied in the field of yeast protein, and can solve the problems that yeast cannot be eaten directly, belching and hiccups, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

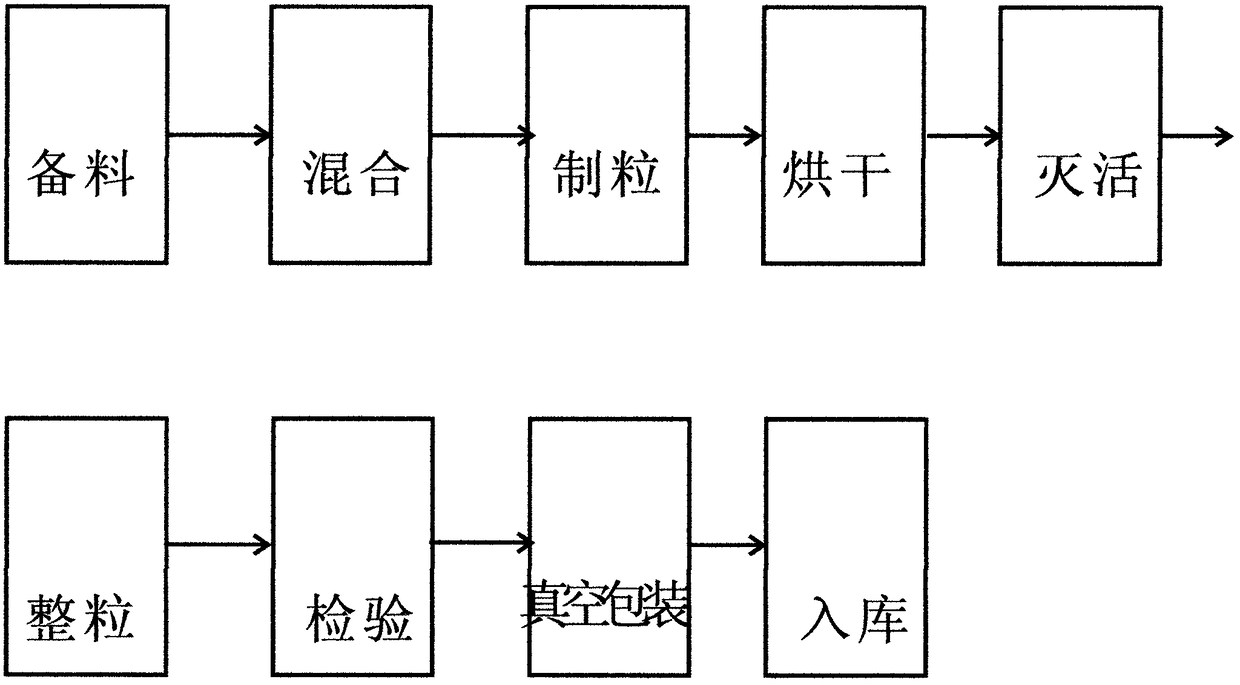

Method used

Image

Examples

Embodiment 1

[0040] In order to realize the present invention, the preferred technical measures in the technical solution are.

[0041] 1. Material preparation: crush the qualified raw material yeast and sucrose to make 5-10% starch paste.

[0042] 2. Mixing: Weigh the raw material yeast and sucrose according to the technological formula, add 5-10% starch paste, and mix evenly. The degree of dryness and wetness can be controlled by the hand to knead it into a lump, and the light can be dispersed into a small lump. Wet wood.

[0043] 3. Granulation: Use a vibrating screen granulator to vibrate the wet material into granules of 20 mesh size.

[0044] 4. Drying: The wet particles are dried in a fluidized bed controlled below 60°C. Whether to dry or not should be grasped by hand feeling and visual observation. The measured moisture content of the pellets should be controlled below 5.5%.

[0045] 5. Inactivation: Increase the drying temperature of the above particles to 100±20℃ for 30-40 minutes to ina...

Embodiment 2

[0051] Experimental application of the invention

[0052] In order to find easily digestible protein for centenarian mothers suffering from cholelithiasis, the applicant spent five years consulting more than 80 domestic medicine and nutrition books, and watched CCTV’s "Healthy Road" program for several years to no avail. I checked some domestic and foreign literatures and found that yeast contains up to 40% protein. In addition, it was known that yeast had long been listed as a digestive aid in the pharmacopoeia, so the idea of edible yeast protein came into being. I bought back the yeast for food processing, which is active dry yeast, for my mother to eat. It was already April 2017. My mother was already skinny and couldn't get up and rely on people to feed. After gradually increasing the amount of edible yeast protein from 1 gram per day, the reaction was hiccups, which made people feel uncomfortable. Another 6 60-90-year-olds also had the same situation. The analysis was due...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com