Production apparatus for antibacterial drug 2,4-hexadienoic acid

A technology for antibacterial drugs and production equipment, which is applied in the field of antibacterial drug 2,4-hexadienoic acid production equipment, and can solve complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

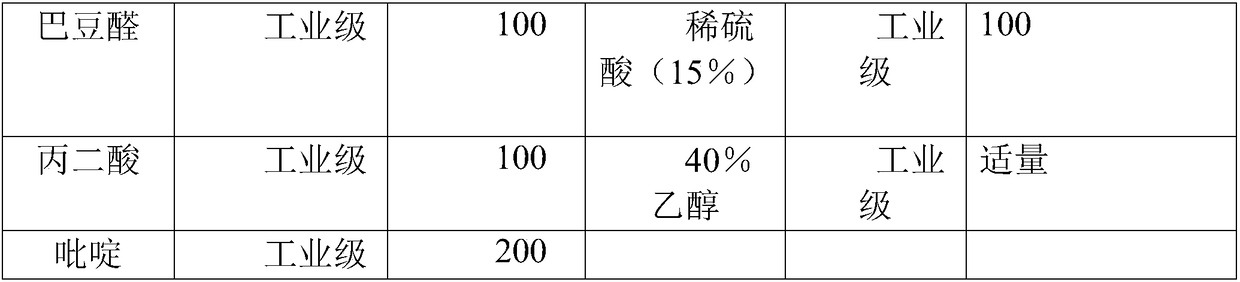

[0010] Production raw materials and dosage

[0011]

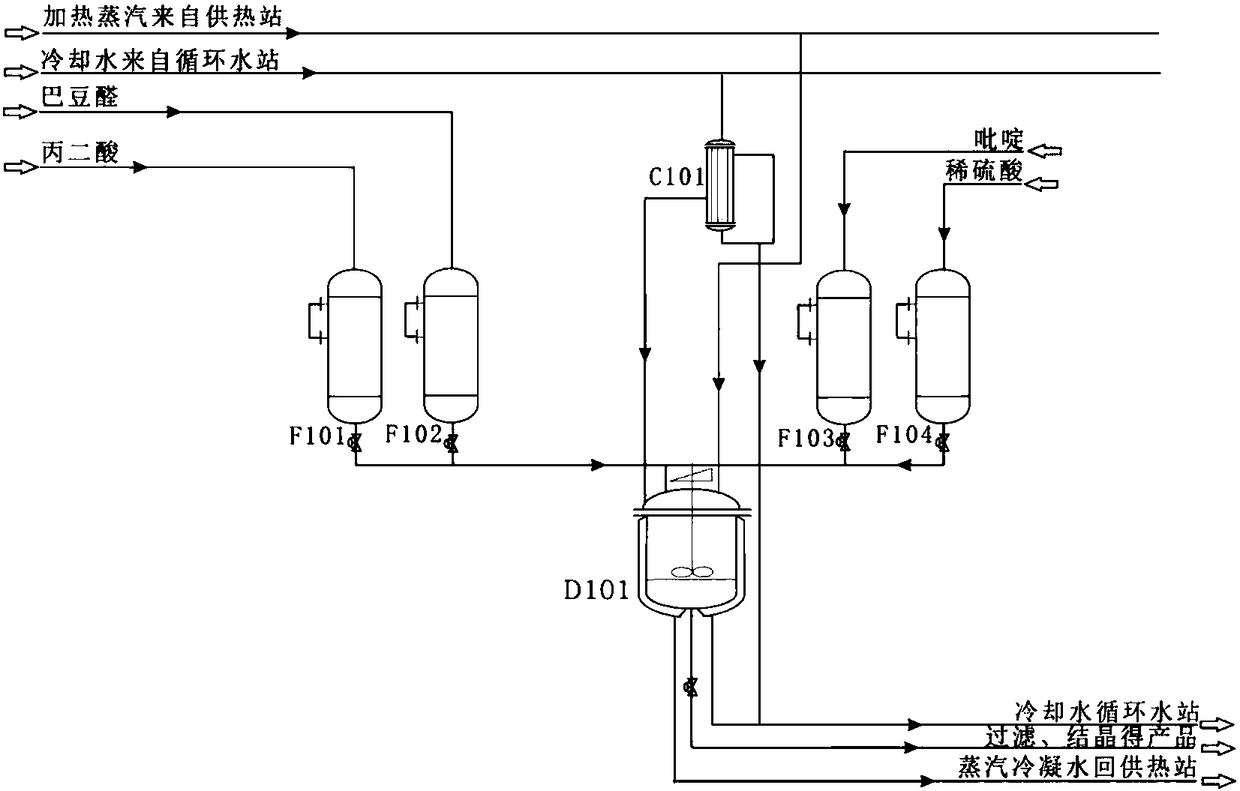

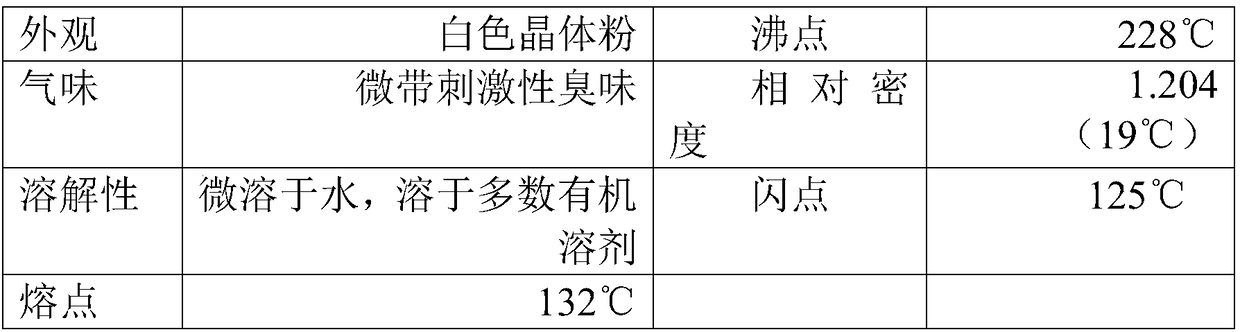

[0012] The production equipment of antibacterial drug 2,4-hexadienoic acid mainly includes: storage tank 1 (F101), storage tank 2 (F102), storage tank 3 (F103), storage tank 4 (F104), condenser (C101) , Reactor (D101), the connection relationship between the various components of the production device is: storage tank 1 (F101) and storage tank 2 (F102) are connected in parallel to the reactor (D101), storage tank 3 (F103) and storage tank 4 (F104) is connected to the reaction kettle (D101) in parallel, and the condenser (C101) is connected to the reaction kettle (D101); wherein, the nominal volume of the reaction kettle (D101) is 300L; the wall thickness of the storage tank 1 (F101) is 6mm; The thickness of the head of storage tank 2 (F102) is 8mm; the thickness of the cone bottom of storage tank 3 (F103) is 7mm. Add pyridine solvent into reaction kettle D101, then add crotonaldehyde and malonic acid, stir at room tempe...

example 2

[0016]

[0017] The production equipment of antibacterial drug 2,4-hexadienoic acid mainly includes: storage tank 1 (F101), storage tank 2 (F102), storage tank 3 (F103), storage tank 4 (F104), condenser (C101) , Reactor (D101), the connection relationship between the various components of the production device is: storage tank 1 (F101) and storage tank 2 (F102) are connected in parallel to the reactor (D101), storage tank 3 (F103) and storage tank 4 (F104) is connected to the reaction kettle (D101) in parallel, and the condenser (C101) is connected to the reaction kettle (D101); wherein, the nominal volume of the reaction kettle (D101) is 350L; the wall thickness of the storage tank 1 (F101) is 7mm; The thickness of the head of storage tank 2 (F102) is 10mm; the thickness of the cone bottom of storage tank 3 (F103) is 9mm. Add pyridine solvent into reaction kettle D101, then add crotonaldehyde and malonic acid, stir at room temperature for 3 hours, then slowly raise the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com