Micro-hole vortex sleeve mixing reactor and application thereof

A mixed reactor and microporous technology, applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve blockage, amplification limitation, limited temperature and pressure resistance problems and other problems, to achieve the effect of enhancing mass transfer and heat transfer, avoiding clogging problems, and high substrate concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

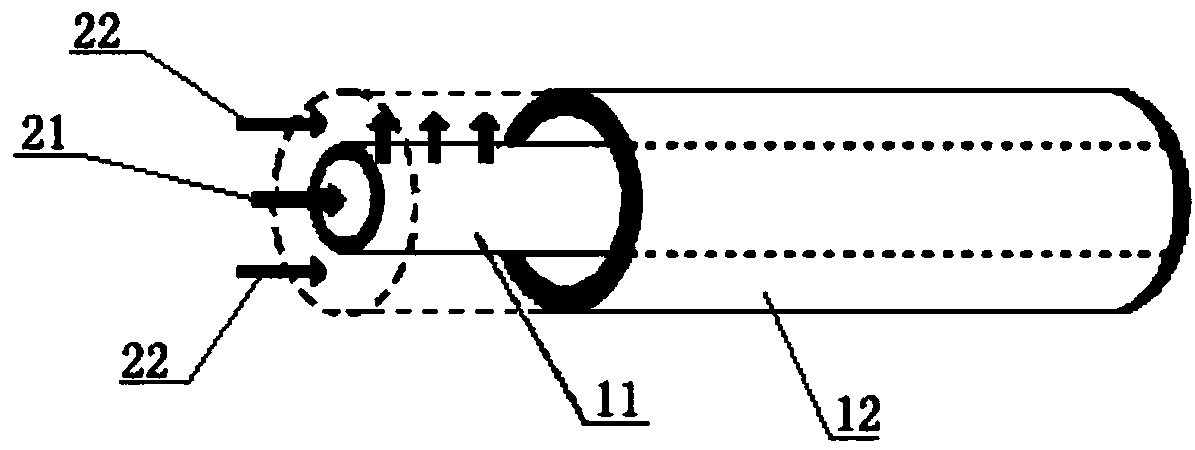

[0075] like Figure 4 Shown is a schematic diagram of the structure of multiple groups of discontinuous micropore arrays, which are composed of multiple groups of arcs parallel to the cross-section on the tube wall. Clockwise spiral; it can also be composed of multiple groups of straight line segments parallel to the axial direction, and these straight line segments progress in turn in the radial and axial directions to present a clockwise or counterclockwise spiral in the circumferential direction of the pipe wall; it can also be composed of neither parallel It is composed of multiple groups of arcs whose cross-section is not parallel to the circumferential direction. Similarly, these arcs progress in turn in the axial direction and present a clockwise or counterclockwise spiral in the circumferential direction of the pipe wall, or clockwise and counterclockwise spirals. A combination of different orders; it can also be formed by combining the various arcs or straight line se...

Embodiment 2

[0081] like Figure 5 As shown, it is a continuous group of micropore arrays, which is composed of multiple sets of arcs parallel to the cross section on the tube wall and multiple sets of straight line segments parallel to the axial direction. These arcs and straight line segments are combined in the axial direction Sequential progression presents a clockwise or counterclockwise spiral in the circumferential direction of the pipe wall; it can also be composed of multiple groups of straight line segments parallel to the axial direction and multiple groups of arcs connected to the pipe wall not parallel to the cross section. The combination of arcs and arcs progresses in turn along the axial direction, showing a clockwise or counterclockwise spiral in the circumferential direction of the pipe wall; it can also be composed of multiple groups of arcs parallel to the cross-section on the pipe wall and multiple groups of arcs not parallel to the axial direction. It is composed of c...

Embodiment 3

[0090] like Image 6 shown is a continuous array of micropores, consisting of sets of arcs that are neither parallel to the cross-section nor parallel to the axial direction, these arcs are parallel to each other like coils wound around the circumference of the tube wall distribution, these arc combinations progress in turn in the axial direction and present a clockwise or counterclockwise spiral in the circumferential direction of the pipe wall; it can also be a combination of clockwise and counterclockwise spirals in different orders and length ratios.

[0091] Image 6 The arrays of mesopores are progressively progressive along the axial direction, showing a counterclockwise or clockwise spiral in the circumferential direction of the tube wall, and the dashed part shows the arc or straight line segment on the back of the inner tube wall:

[0092] (j) Similar to the counterclockwise spiral continuous multiple groups of micropore arrays distributed in parallel between the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com