Nano-gold/manganese dioxide/graphene-carbon nanotube three-dimensional structural nano complex and hydrogen peroxide sensor prepared by using complex

A nanocomposite, carbon nanotube technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical/physical process, etc., can solve the problem that the particle size is difficult to control, uneven distribution, The problems of different sizes of metal nanoparticles can achieve the effect of high selective detection, simple preparation method and extended application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

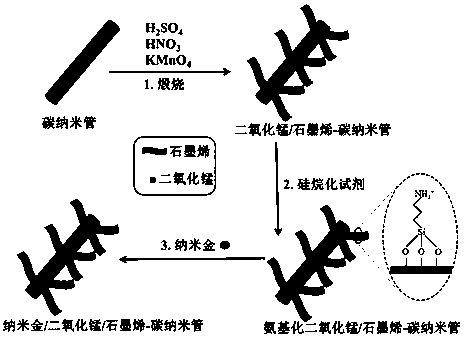

[0031] A preparation method of nano-gold / manganese dioxide / graphene-carbon nanotube three-dimensional structure nanocomposite, which comprises the following steps (see the schematic diagram of the preparation process in figure 1 ):

[0032] 1) Disperse 1.0 g of carbon nanotubes in 100 mL of distilled water and add 2 mL of concentrated H 2 SO4 and 6 mL concentrated HNO 3 After stirring at 70 °C for 3 hours; then placed in ice water and rapidly cooled to 0 °C, and then added 6 mL of concentrated H 2 SO 4 , heated to 55°C after mixing;

[0033] 2) Add 3.0 g KMnO to the product obtained in step 1) 4 , stirred and reacted for 2.5 hours, then heated to 90 ° C, the obtained product was filtered and dried, and kept at 190 ° C for 4 hours to obtain manganese dioxide / graphene-carbon nanotube material;

[0034] 3) Take 11 g of the manganese dioxide / graphene-carbon nanotube material obtained in step 2), add 18 mL of absolute ethanol, 3 mL of distilled water, 3 mL of concentrated ammo...

Embodiment 2

[0050] A preparation method of nano-gold / manganese dioxide / graphene-carbon nanotube three-dimensional structure nanocomposite, which comprises the following steps:

[0051] 1) Disperse 0.8 g of carbon nanotubes in 100 mL of distilled water, add 1 mL of concentrated H 2 SO 4 and 5 mL of concentrated HNO 3 After stirring at 65 °C for 2 hours; then placed in ice water and rapidly cooled to 0 °C, and then added 5 mL of concentrated H 2 SO 4 , and heated to 50°C after mixing;

[0052] 2) Add 2.8 g of KMnO to the product obtained in step 1) 4 , stirred and reacted for 2 hours, then heated to 85 ° C, the obtained product was filtered and dried, and kept at 180 ° C for 3 hours to obtain manganese dioxide / graphene-carbon nanotube material;

[0053] 3) Take 10 g of the manganese dioxide / graphene-carbon nanotube material obtained in step 2), add 15 mL of absolute ethanol, 2 mL of distilled water, 2 mL of concentrated ammonia and 200 µL of 3-aminopropyltrimethoxysilane in sequence, ...

Embodiment 3

[0057] A preparation method of nano-gold / manganese dioxide / graphene-carbon nanotube three-dimensional structure nanocomposite, which comprises the following steps:

[0058] 1) Disperse 1.2 g of carbon nanotubes in 100 mL of distilled water, add 3 mL of concentrated H 2 SO 4 and 7 mL concentrated HNO 3 After stirring at 75 °C for 4 hours; then placed in ice water and rapidly cooled to 0 °C, and then added 7 mL of concentrated H 2 SO 4 , heated to 60°C after mixing;

[0059] 2) Add 3.2 g of KMnO to the product obtained in step 1) 4 , stirred and reacted for 2.5 hours, then heated to 95 ° C, the obtained product was filtered and dried, and kept at 200 ° C for 4 hours to obtain manganese dioxide / graphene-carbon nanotube material;

[0060] 3) Take 12 g of the manganese dioxide / graphene-carbon nanotube material obtained in step 2), add 20 mL of absolute ethanol, 4 mL of distilled water, 4 mL of concentrated ammonia and 400 µL of 3-aminopropyltrimethoxysilane in sequence, The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com