Centrifugal type micro-fluidic chip

A microfluidic chip and centrifugal technology, which is applied in the field of life science and medical testing, can solve the problems of increasing the complexity of chip manufacturing and processing costs, affecting liquids, and not completely solving the problem of uniform distribution of air bubbles in samples, so as to avoid cross-contamination of samples , uniform distribution, and uniform flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

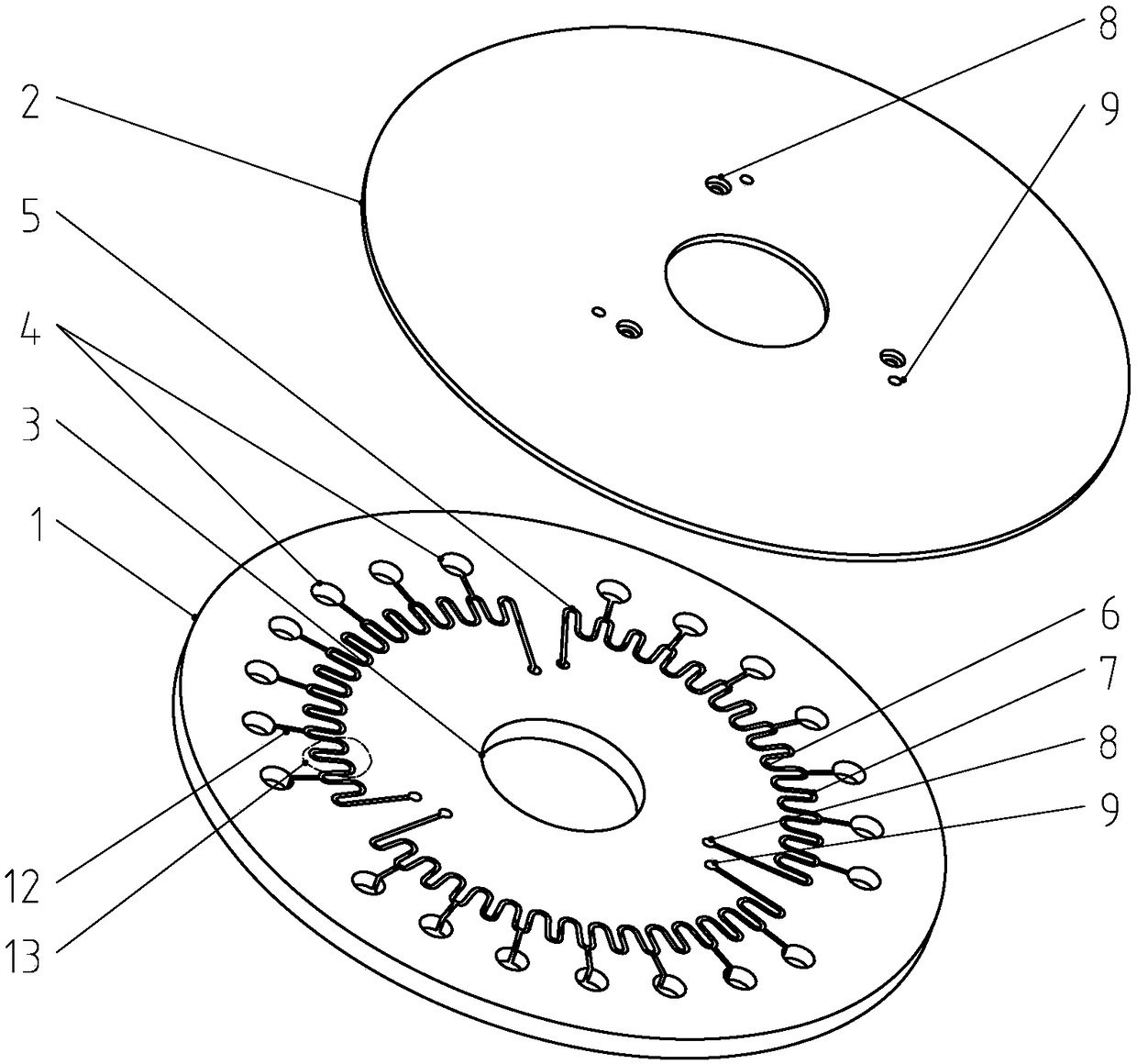

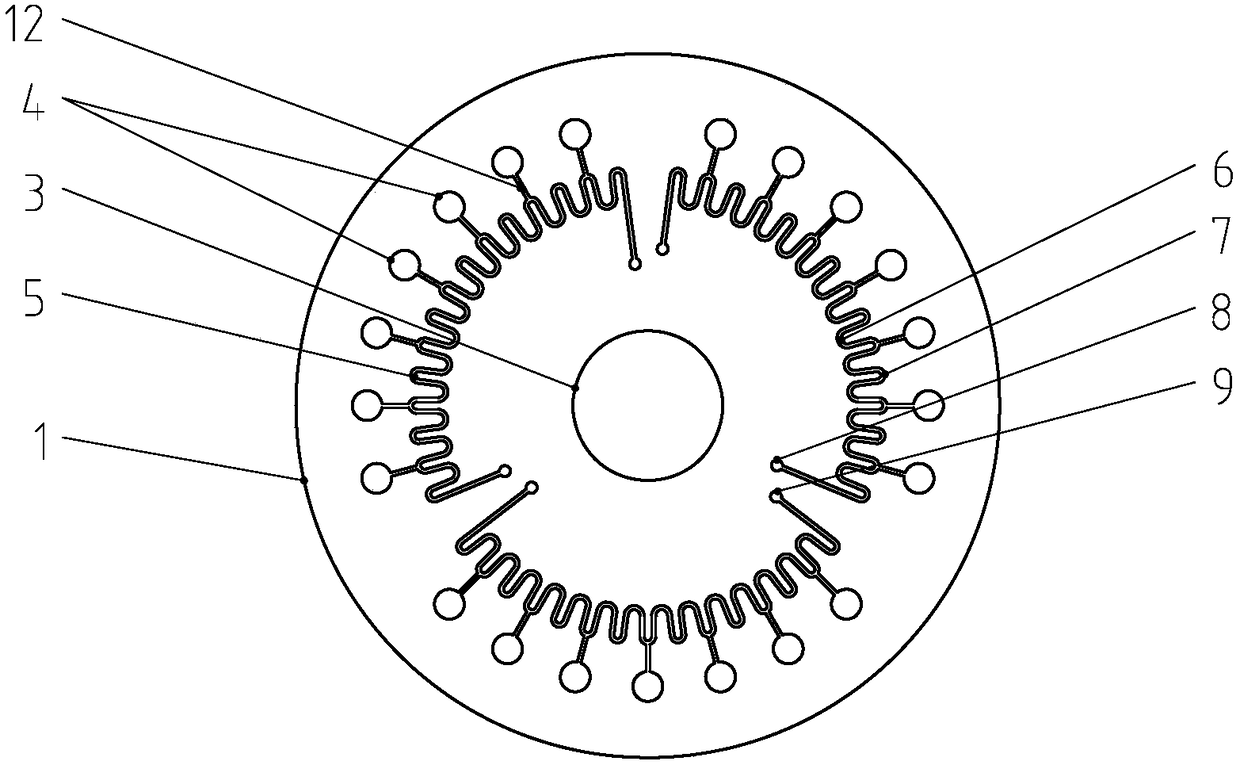

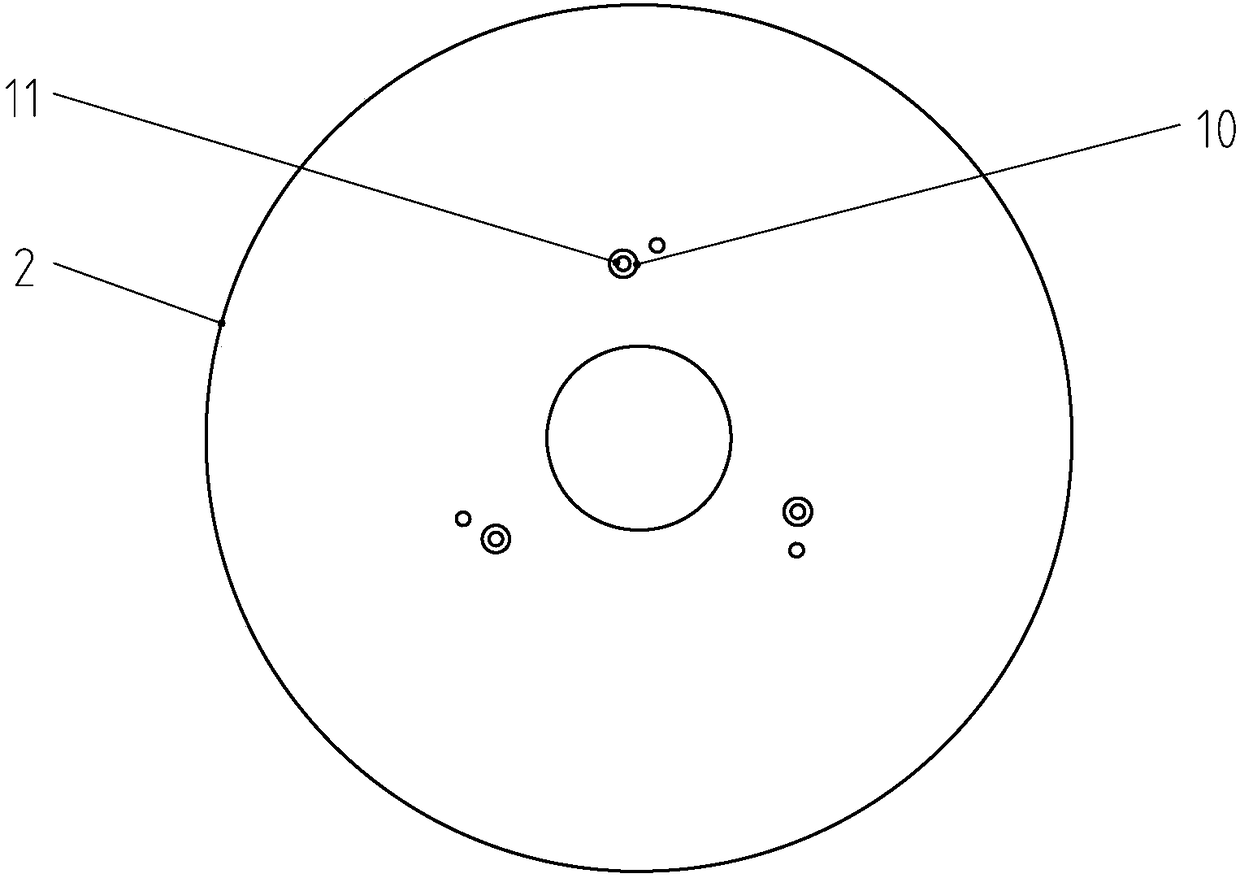

[0025] Such as figure 1 A centrifugal microfluidic chip shown includes a substrate 1 and a cover sheet 2 tightly fitted with the substrate. Both the substrate and the cover sheet are circular, the thickness of the substrate is 3mm, and the thickness of the cover sheet is 1mm. The center of the centrifugal microfluidic chip is There is a central through hole 3, and the central through hole runs through the substrate and the cover sheet. Such as figure 2 As shown, there are 21 circumferentially distributed reaction holes 4 and 3 circumferentially distributed main channels 5 connecting the reaction holes on the end surface of the base plate and the cover sheet, and each main channel is connected to 7 reaction holes. The volume of each reaction well is 25 μL, and the volume of the main channel between every two adjacent reaction wells is twice the volume of each reaction well. Before using the centrifugal microfluidic chip, different reaction wells can be preloaded with substan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Large hole diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com