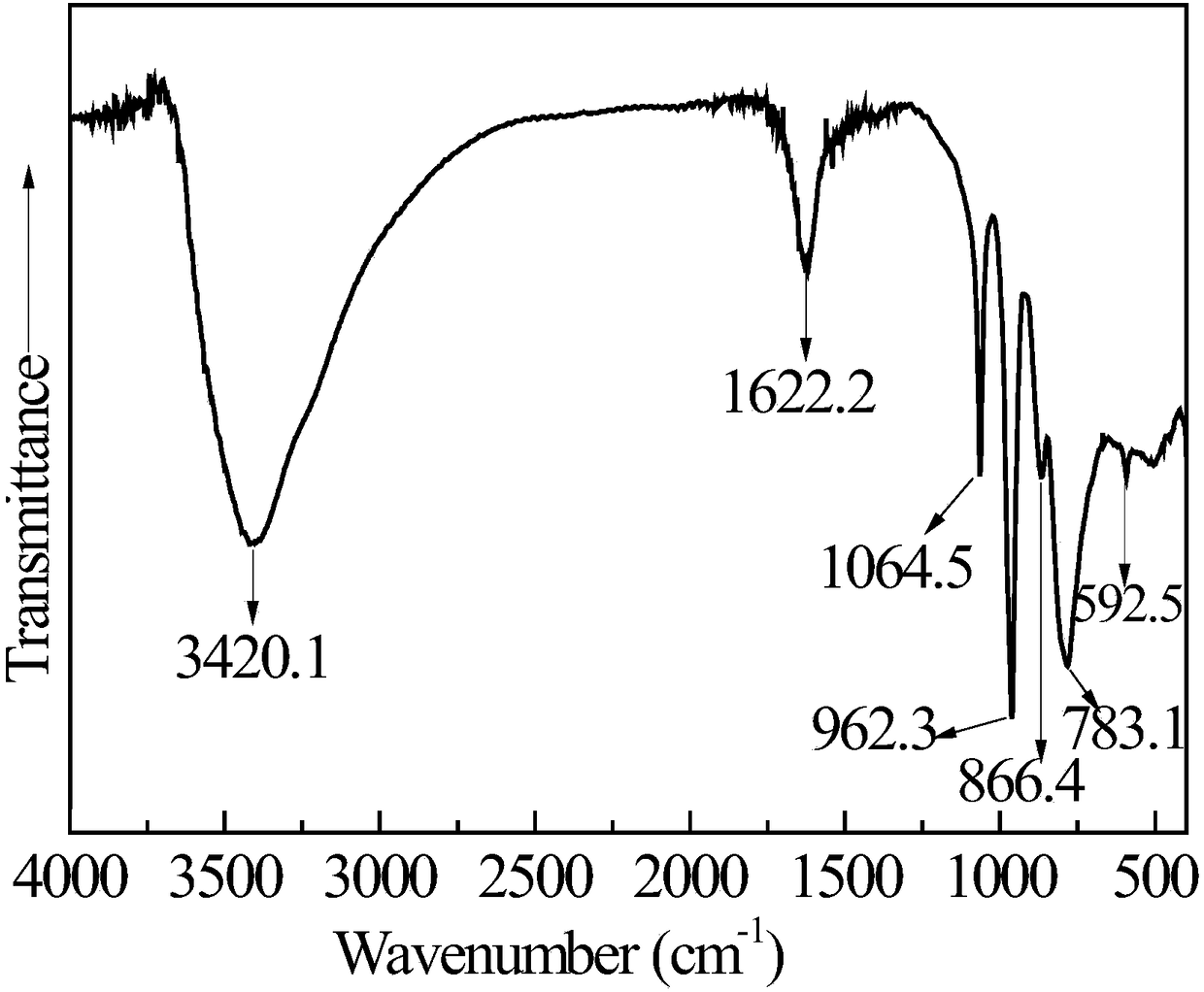

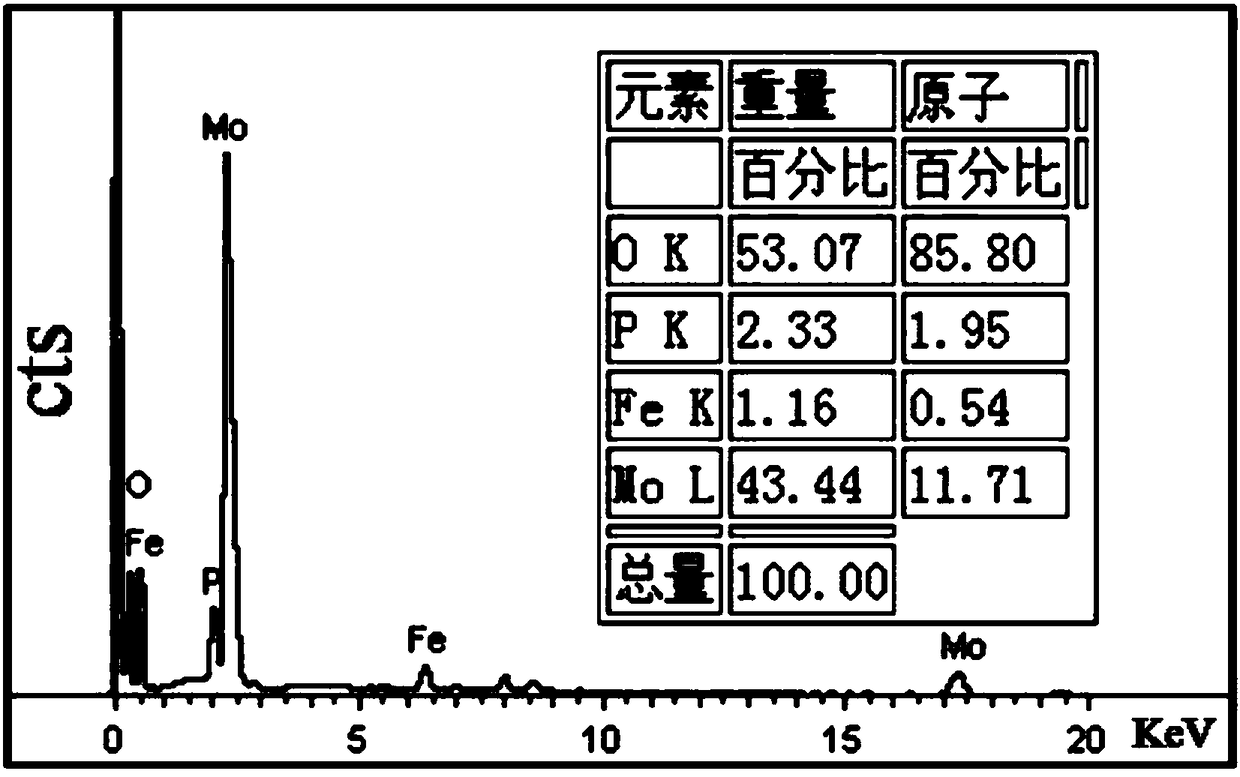

Preparation method of iron phosphomolybdate comprising keggin structure

A technology of phosphomolybdic acid and liquid phase method, which is applied in the direction of phosphorus oxyacids, etc., can solve the problems of no keggin structure iron phosphomolybdate compound, no report, etc., and achieve low impurity ion content, low price and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Weigh 0.0119mol phosphomolybdic acid crystal and put it into a beaker, add distilled water, stir the glass, put it into a water bath with a temperature of 60°C and continue stirring until the turbid solution turns into a yellow clear liquid; weigh 0.0119mol Fe(OH) 3 Add it to the phosphomolybdic acid solution, start the stirrer, react in a water bath at a temperature of 60 °C, and continue to stir it fully. At the same time, add the phosphomolybdic acid solution dropwise to control the pH to about 1.0 to obtain a reddish-brown precipitate. Note that centrifugation or filtration is not allowed here. , because the obtained precipitate is very fine, centrifugation and filtration cannot separate the precipitate from the solution, but the solution containing the precipitate should be distilled under reduced pressure to obtain a reddish-brown paste, and finally dried at 80 °C for 4 hours by blasting to obtain brown phosphorus Iron molybdate 20.50g, in Fe[PMo 12 O 40 ], the y...

Embodiment 2

[0023] Weigh 0.0129mol of phosphomolybdic acid crystals into a beaker, add distilled water, stir in the glass, put into a water bath at 60°C and continue stirring until the turbid solution turns into a yellow clear liquid; weigh 0.0109mol Fe(OH) 3 Add it to the phosphomolybdic acid solution, start the stirrer, react in a water bath at a temperature of 65°C, and continue to stir thoroughly. At the same time, add the phosphomolybdic acid solution dropwise to control the pH to about 2.0 to obtain a reddish-brown precipitate. Note that centrifugation or filtration is not allowed here. , because the obtained precipitate is very fine, centrifugation and filtration cannot separate the precipitate from the solution, but the solution containing the precipitate should be distilled under reduced pressure to obtain a reddish-brown paste, and finally dried at 80 °C for 4 hours by blasting to obtain brown phosphorus Iron molybdate 20.38g, in Fe[PMo 12 O 40 ], the yield was 82.64%.

Embodiment 3

[0025] Weigh 0.01mol phosphomolybdic acid crystal and put it into a beaker, add distilled water, stir the glass, put it into a water bath with a temperature of 60°C and continue stirring until the turbid solution turns into a yellow clear liquid; weigh 0.0157mol Fe(OH) 3 Add it to the phosphomolybdic acid solution, start the stirrer, react in a water bath at a temperature of 55°C, and continue to stir thoroughly. At the same time, add the phosphomolybdic acid solution dropwise to control the pH to about 3.0 to obtain a reddish-brown precipitate. Note that centrifugation or filtration is not allowed here. , because the obtained precipitate is very fine, centrifugation and filtration cannot separate the precipitate from the solution, but the solution containing the precipitate should be distilled under reduced pressure to obtain a reddish-brown paste, and finally dried at 70 °C for 5 hours by blasting to obtain brown phosphorus Iron molybdate 15.47g, in Fe[PMo 12 O 40 ], the yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com