Electric-heating anti-icing and de-icing system and preparation method thereof

An anti-icing and electric heating technology, applied in chemical instruments and methods, heat exchange materials, coatings, etc., can solve the problems of power density attenuation of composite materials, complex preparation process, high cost, and achieve good power stability and construction technology. Simple, thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

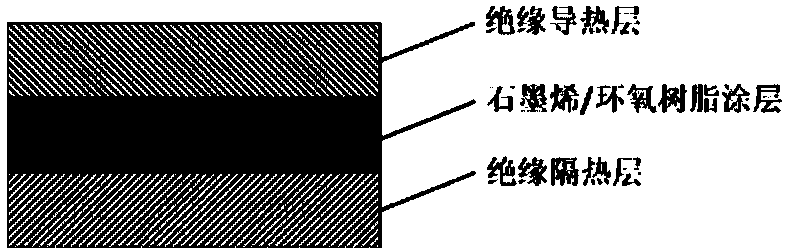

[0047] In this embodiment, an electrothermal anti-icing and deicing system for wind turbine blades is prepared, and the system includes a heat-generating paint layer, an insulating and heat-conducting layer, and an insulating and heat-insulating layer. The exothermic coating of described exothermic coating layer is prepared by dispersing the following components: graphene: 5 parts, Nanya bisphenol A type 128 epoxy resin: 50 parts, auxiliary agent (curing agent is ethylenediamine, defoamer It is emulsified silicone oil, the thickener is methyl cellulose, the ratio of the three is 70:10:20): 5 parts, 500 parts of xylene; the insulating and heat-conducting layer is filled with alumina heat-conducting filler Nanya bisphenol A type 128 Prepared from epoxy resin, wherein the mass ratio of aluminum oxide thermal conductive filler to 128 epoxy resin is 20:100; the insulation and heat insulation layer is 6522 high-strength glass fiber cloth of BGF company.

[0048] The specific prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com