Microbial agent and its application in zearalenone degradation

A technology of zearalenone and bacterial agent, applied in the field of microorganisms, can solve the problems of long degradation time and the need to improve the degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

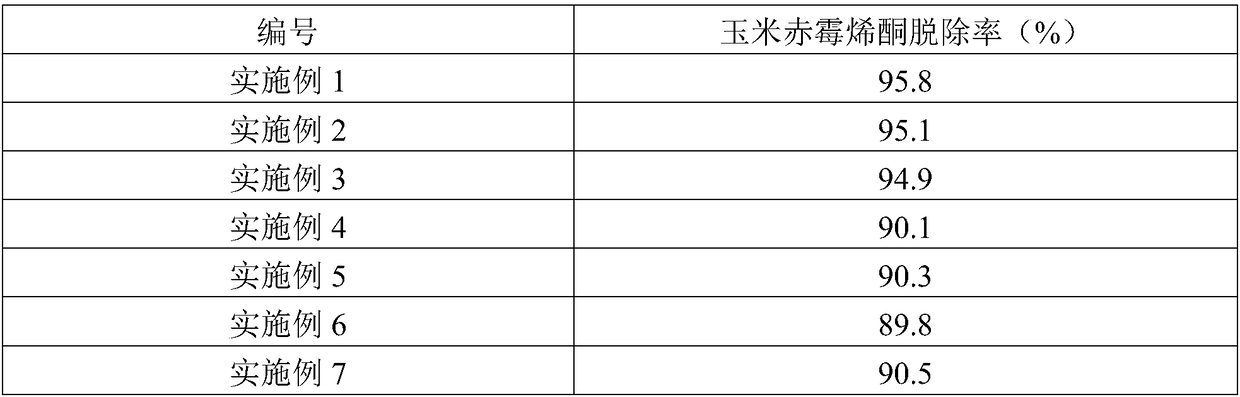

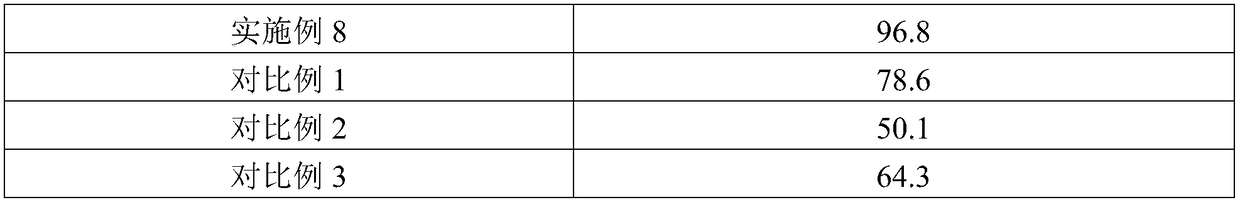

Examples

preparation example Construction

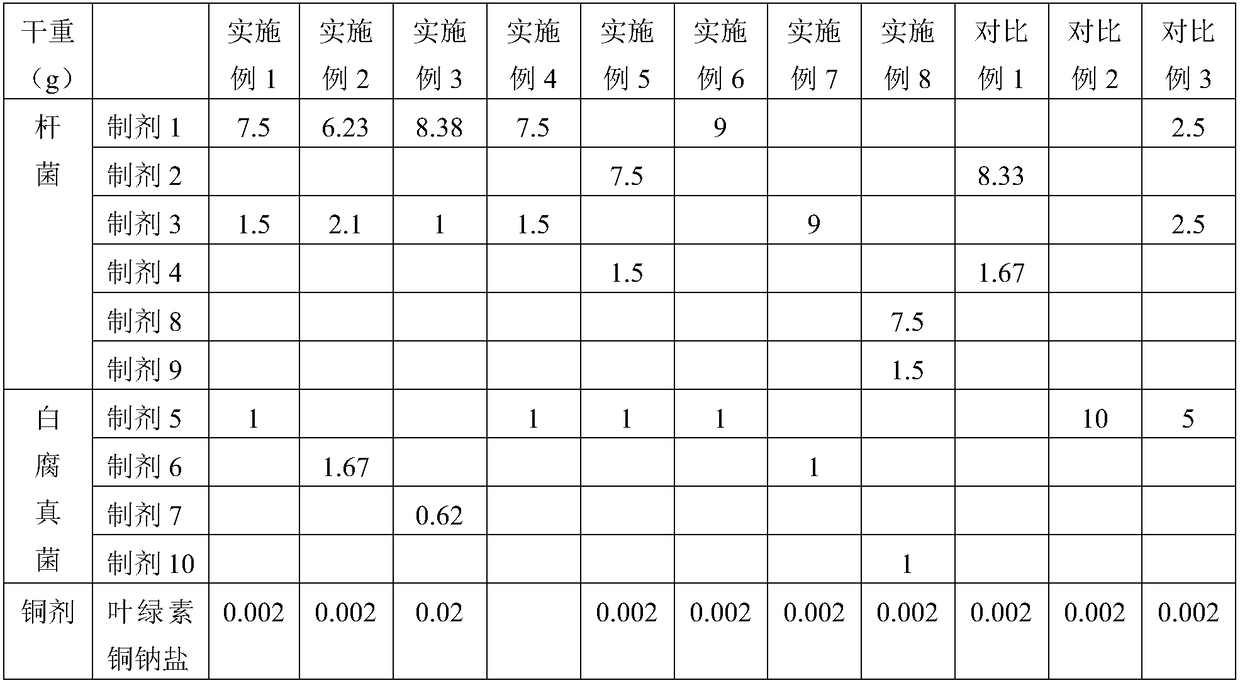

[0036] The present invention also provides a preparation method of the above bacterial agent, the method comprising: separately cultivating white rot fungi and bacilli separately, and mixing the obtained white rot fungi and bacilli to obtain the bacterial agent of the present invention, wherein, the dry weight In total, the weight ratio of the white rot fungus to the bacillus is 1:2-50, preferably 1:5-40.

[0037] In the second aspect, the present invention also provides the application of the above bacterial agent in removing zearalenone.

[0038] In the third aspect, the present invention also provides a grain, oil or feed, wherein the grain, oil or feed contains the above bacterial agent.

[0039] In a preferred situation, relative to 1 kg of grain, oil or feed, the content of the bacterial agent may be at least 0.001 g, preferably at least 0.01 g, more preferably at least 0.1 g, and even more preferably at least 1 g by dry weight.

[0040] In the present invention, the te...

preparation example 1

[0062] Bacillus subtilis (preservation number is CGMCC NO.13138) was inoculated in liquid LB medium with 1% inoculation amount, cultivated at 150rpm and 30°C, and after cultivating for 48h, the viable cell concentration was 1×10 9 CFU / mL of bacterial liquid, and then the obtained bacterial liquid is made into dry powder, wherein the number of live bacteria per gram of dry powder is 1×10 9 CFU, that is, preparation 1 was obtained.

preparation example 2

[0064] Bacillus subtilis (preservation number is CGMCC NO.9463) was inoculated in liquid LB medium with 1% inoculation amount, cultivated at 150rpm and 30°C, and after cultivating for 48h, the concentration of viable cells was 1×10 9 CFU / mL of bacterial liquid, and then the obtained bacterial liquid is made into dry powder, wherein the number of live bacteria per gram of dry powder is 1×10 9 CFU, formulation 2 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com