Novel hot air-microwave composite in-place hot recycling complete set and construction technology thereof

A technology of a complete set of units and a re-mixing regenerator, which is used in road repair, roads, roads, etc., can solve the problems of large temperature gradient between layers, large heat loss, and long interval time, so as to achieve a small temperature gradient between layers and reduce heat. The effect of leakage, moderate heating depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

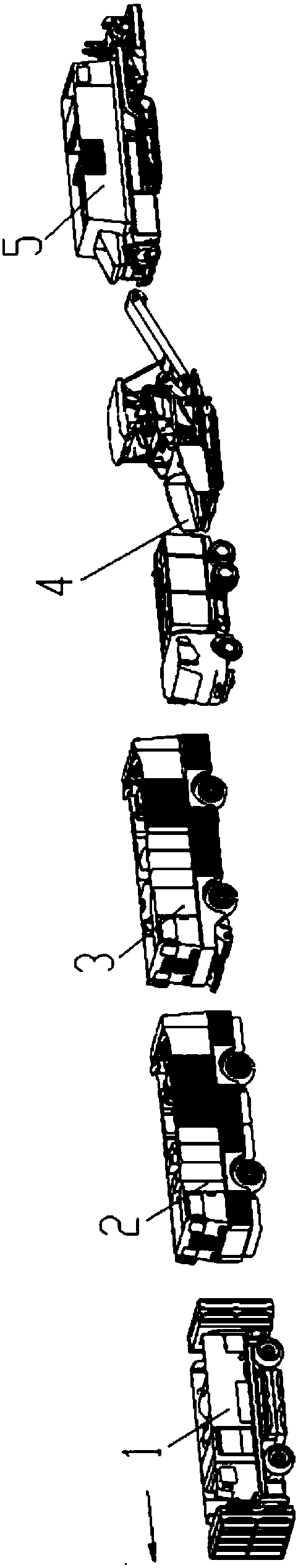

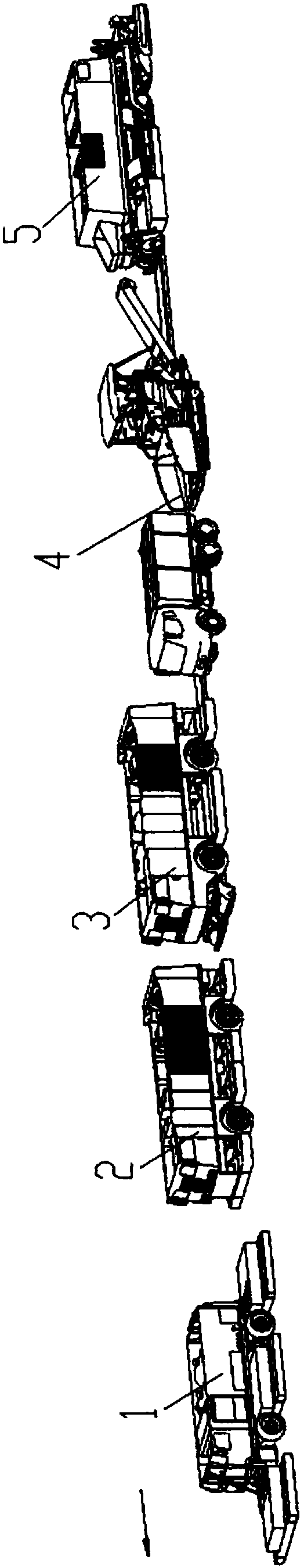

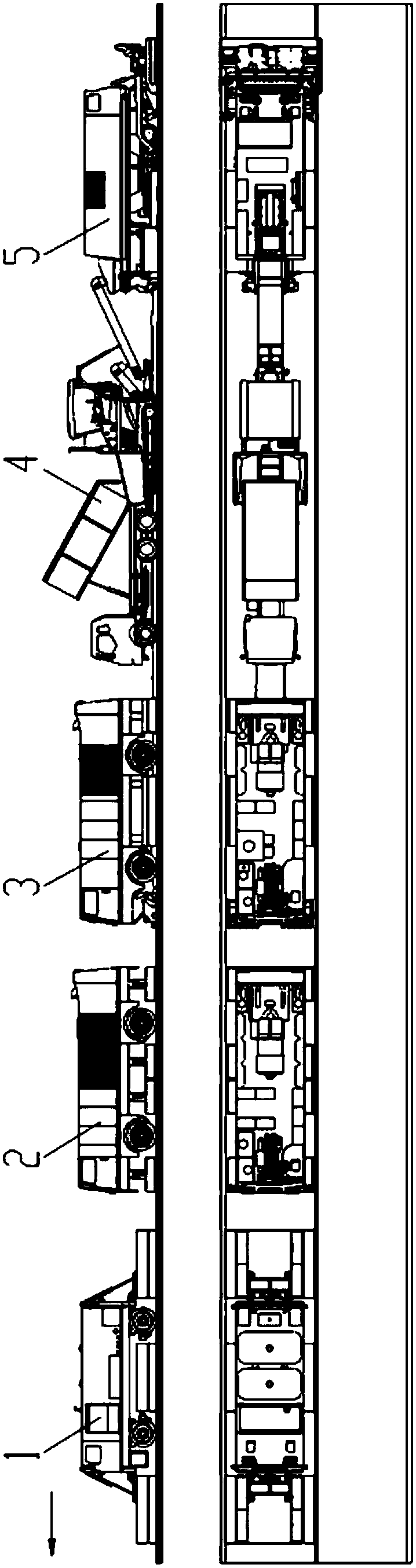

[0056] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention. Such as Figure 1 to Figure 5 As shown, the novel hot-air microwave composite in-situ heat regeneration complete unit of the present invention includes a hot-air heater 1 arranged at the forefront of the complete unit, a microwave heater 2 is arranged at the rear end of the hot-air heater 1, and a microwave heater 2 is arranged at the rear end of the microwave heater 2. A microwave heating milling machine 3 is provided, and several sets of dump trucks + multifunctional feeding machine feeding combinations 4 are arranged at the rear end or side of the microwave heating milling machine 3, and the remixing and recycling machine 5 is arranged at the front end of the complete set.

[0057] In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com