Auxiliary tool for manufacturing PTFE gasket and method for manufacturing same

A technology of auxiliary tools and gaskets, which is applied in printed circuit manufacturing, electrical components, printed circuit dielectrics, etc., can solve the problems of high mold cost, many burrs on the edge of gaskets, low gasket accuracy, etc., to reduce processing costs, protect The effect of the platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

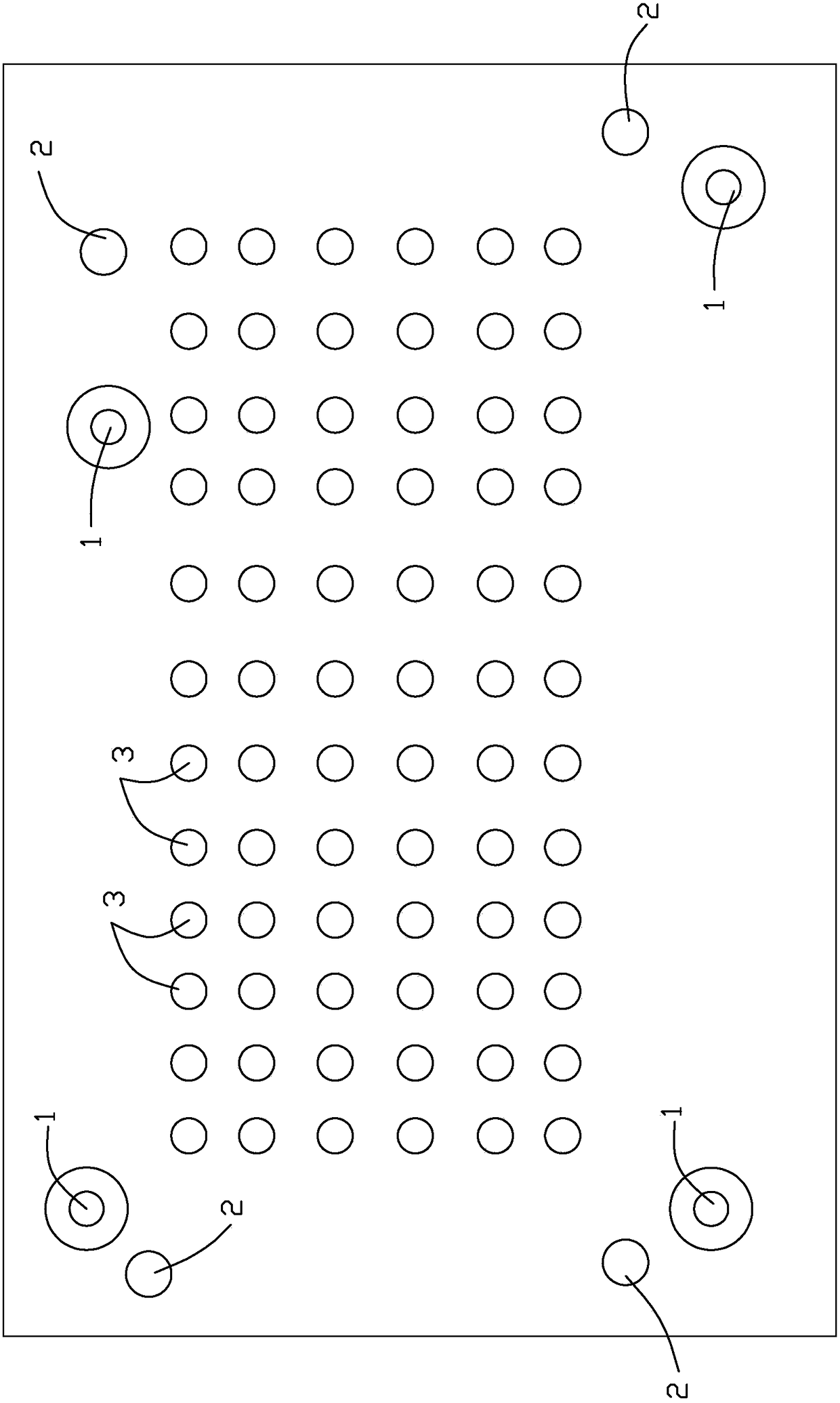

[0024] refer to figure 1 , the invention provides an auxiliary tool for making PTFE gaskets, including a flat plate, the flat plate is a copper clad laminate, the thickness of the copper clad laminate is 0.71mm-1.0mm, four optical positioning patterns 1, four optical alignment The hole 2 and several air guide holes 3, the optical alignment hole 2 and the optical positioning pattern 1 are arranged adjacent to each other, and all of them adopt the anti-reverse anti-fooling design. The optical alignment pattern 1 is ring-shaped with an outer diameter of 3.2mm, and the optical alignment hole 2 has an aperture diameter of 0.8mm-1.2mm. Also be provided with some air guide holes 3 on the flat plate, when the air guide holes 3 are processed, the flatness of the air guide holes 3 should be guaranteed. The air guide holes 3 are arranged on the auxiliary tool corresponding to the air suction holes of the laser drilling equipment. In this embodiment, the air guide holes 3 are evenly dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com