Three-dimensional moisture preservation factor

A moisturizing factor, three-dimensional technology, applied in the field of daily chemical products, can solve the problems of allergies, low usage, poor stability, etc., and achieve the effect of light moisturizing, strong moisturizing, and moisturizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

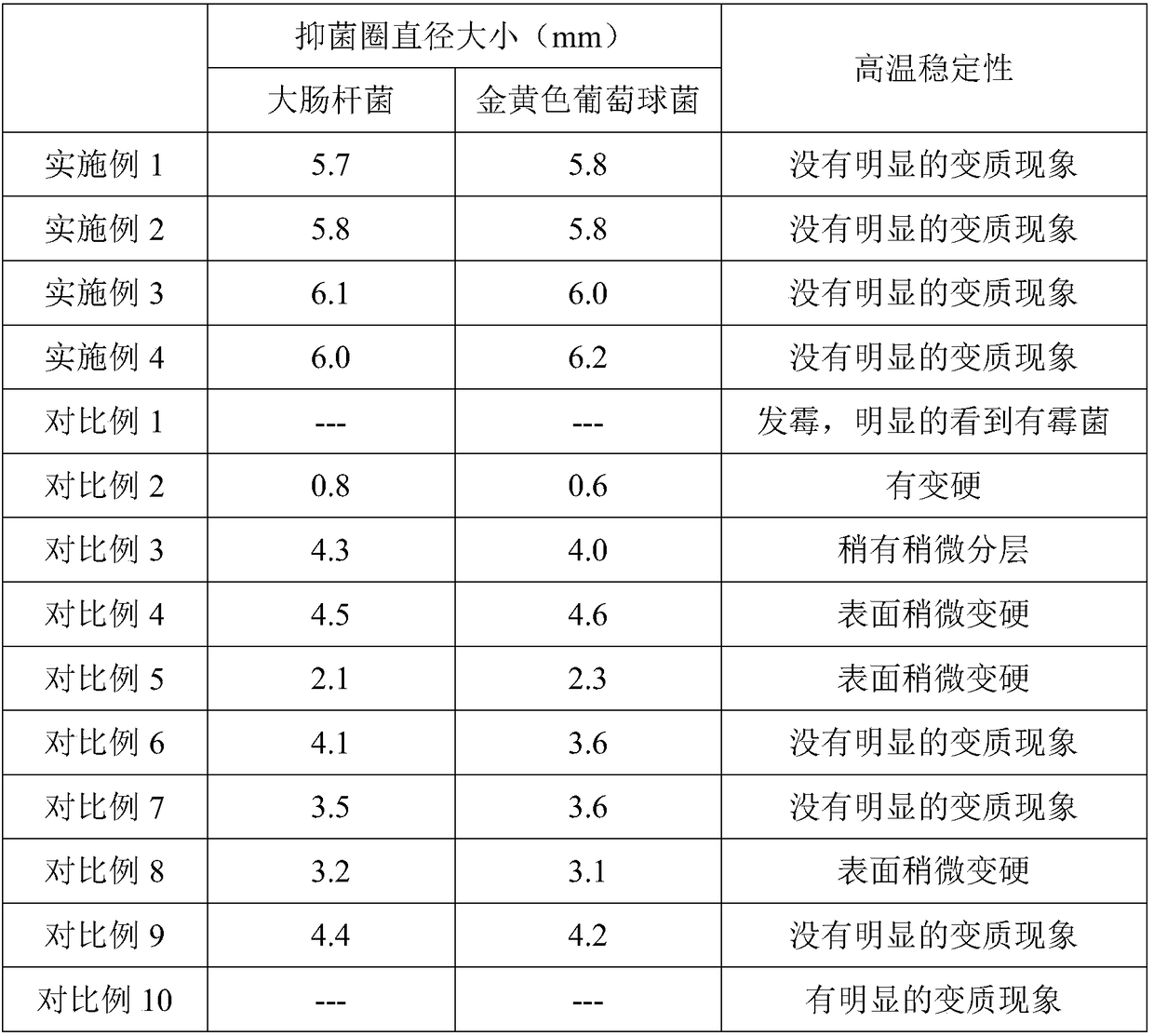

Examples

preparation example Construction

[0034] In a preferred embodiment, the preparation method of the malt extract comprises the following steps:

[0035] (1) choose malt germinated for 2 days and 6 days as raw material, and pulverize;

[0036] (2) Weigh 10g of crushed malt, add 120ml of 25wt% ethanol to it, stir and mix, then ultrasonically treat for 10 minutes, then stir and extract at 75°C for 3 hours, collect the filtrate by filtration; add 0.03g of titanium dioxide powder to the resulting filtrate , and filtered under a low-pressure mercury lamp for 15 seconds, the filtrate was collected, concentrated, and dried to obtain A powder;

[0037] (3) Add 60ml of 70wt% ethanol and 2g of additives to the filter residue obtained by filtering in step (2), and extract by microwave for 45min at a power of 480W, filter, collect the filtrate, concentrate, and dry to obtain B powder;

[0038] (4) B powder and A powder are mixed in a weight ratio of 1:1.5-3.5 to obtain the malt extract.

[0039] The applicant found that wh...

Embodiment 1

[0053] Example 1 provides a three-dimensional moisturizing factor. The three-dimensional moisturizing factor, in parts by weight, includes sugar isomer 30, ectoine 5, malt extract 1, caprylyl hydroxamic acid 0.1, 1,2 hexanediol 0.1, sodium polyglutamate 0.1, hyaluronic acid 0.01, sodium hyaluronate 0.01, water 68.

[0054] The preparation method of described malt extract comprises the steps:

[0055] (1) choose malt germinated for 2 days and 6 days as raw material, and pulverize;

[0056] (2) Weigh 10g of crushed malt, add 120ml of 25wt% ethanol to it, stir and mix, then ultrasonically treat for 10 minutes, then stir and extract at 75°C for 3 hours, collect the filtrate by filtration; add 0.03g of titanium dioxide powder to the resulting filtrate , and filtered under a low-pressure mercury lamp for 15 seconds, the filtrate was collected, concentrated, and dried to obtain A powder;

[0057] (3) Add 60ml of 70wt% ethanol and 2g of additives to the filter residue obtained by fi...

Embodiment 2

[0062] Example 2 provides a three-dimensional moisturizing factor, the three-dimensional moisturizing factor, in parts by weight, including sugar isomers 30, ectoine 12, malt extract 5, caprylyl hydroxamic acid 1.5, 1,2 hexanediol 0.4, sodium polyglutamate 0.5, hyaluronic acid 0.2, sodium hyaluronate 0.5, water 80.

[0063] The preparation method of described malt extract comprises the steps:

[0064] (1) choose malt germinated for 2 days and 6 days as raw material, and pulverize;

[0065](2) Weigh 10g of crushed malt, add 120ml of 25wt% ethanol to it, stir and mix, then ultrasonically treat for 10 minutes, then stir and extract at 75°C for 3 hours, collect the filtrate by filtration; add 0.03g of titanium dioxide powder to the resulting filtrate , and filtered under a low-pressure mercury lamp for 15 seconds, the filtrate was collected, concentrated, and dried to obtain A powder;

[0066] (3) Add 60ml of 70wt% ethanol and 2g of additives to the filter residue obtained by fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com