Rhubarb ultramicro powder-containing film spraying agent for traumatic wounds and preparation method thereof

A technology of ultra-fine powder and film-spraying agent, which is applied in the field of medical devices, can solve the problems of inability to absorb powder and treat wounds with skin lesions, and achieve the effect of promoting wound healing, enhancing the effect, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

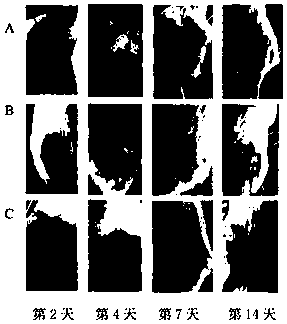

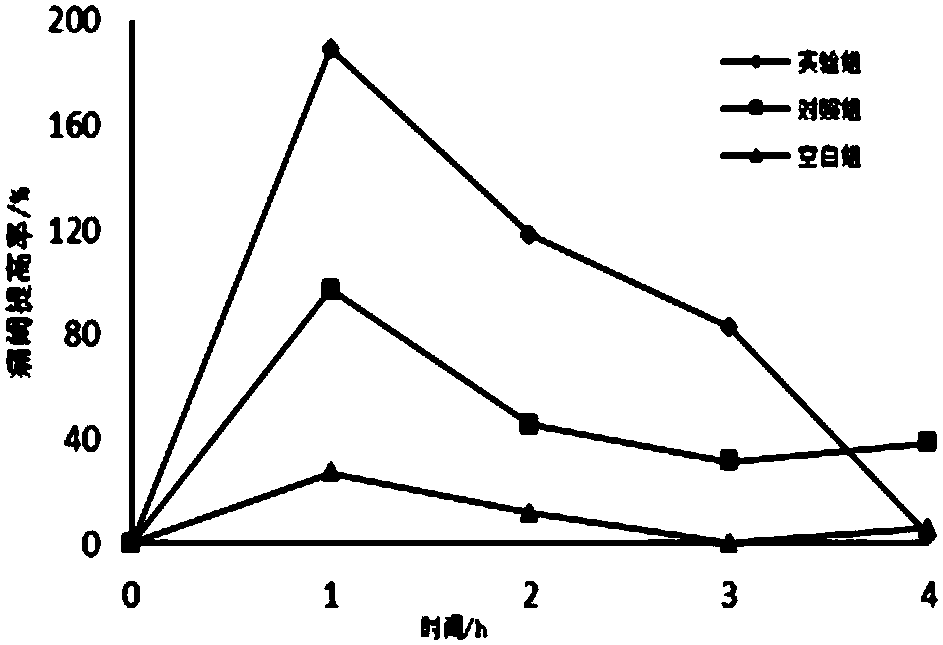

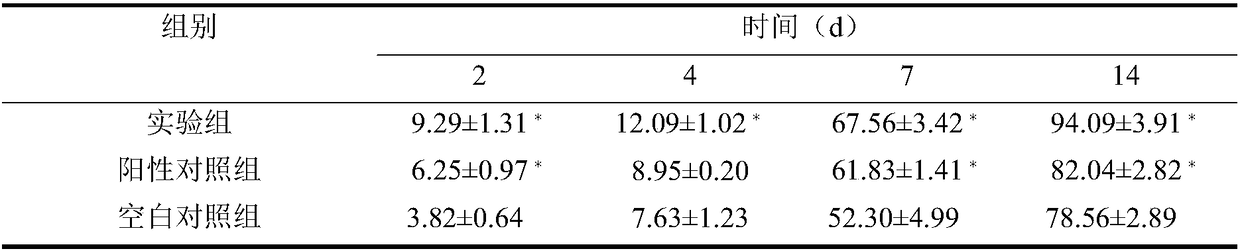

Image

Examples

Embodiment 1

[0056] A spray film agent for traumatic wounds containing rhubarb superfine powder, which consists of the following raw material components in parts by weight:

[0057] Rhubarb: 0.15%

[0058] Povidone K30 (PVP-K30): 2.0%

[0059] Chitosan hydrochloride: 1.0%

[0060] Modifier: 2.5%

[0061] Deionized water: balance

[0062] The modifying agent is composed of hydroxypropyl methylcellulose and glycerin, wherein the mass volume percentage of hydroxypropyl methylcellulose is 0.5%, and the mass volume percentage of glycerin is 2.0%.

[0063] A method for preparing a film-spraying agent for traumatic wounds containing rhubarb superfine powder, comprising the following process steps:

[0064] (1) Wash the rhubarb medicinal material and dry it for later use. The rhubarb is initially pulverized and passed through a 100-mesh sieve to obtain rhubarb coarse powder. Take the dried rhubarb coarse powder, pulverize it in a planetary ball mill, and pass through a 200-mesh sieve to obta...

Embodiment 2

[0069] A spray film agent for traumatic wounds containing rhubarb superfine powder, which consists of the following raw material components in parts by weight:

[0070] Rhubarb: 0.3%

[0071] Povidone K30 (PVP-K30): 3.0%

[0072] Chitosan hydrochloride: 2.0%

[0073] Modifier: 2.3%

[0074] Deionized water: balance

[0075] The modifying agent is composed of special low-ester pectin and hydroxypropyl methylcellulose, wherein the mass volume percentage of special low-ester pectin is 2.0%, and the mass volume percentage of hydroxypropyl methylcellulose is 0.3%.

[0076] A method for preparing a film-spraying agent for traumatic wounds containing rhubarb superfine powder, comprising the following process steps:

[0077] (1) Wash the rhubarb medicinal material and dry it for later use. The rhubarb is initially pulverized and passed through a 100-mesh sieve to obtain rhubarb coarse powder. Take the dried rhubarb coarse powder, pulverize it in a planetary ball mill, and pass t...

Embodiment 3

[0082] A spray film agent for traumatic wounds containing rhubarb superfine powder, which consists of the following raw material components in parts by weight:

[0083] Rhubarb: 0.45%

[0084] Povidone K30 (PVP-K30): 3.0%

[0085] Chitosan hydrochloride: 1.0%

[0086] Modifier: 2.5%

[0087] Deionized water: balance

[0088] The modifier is composed of special low-ester pectin, hydroxypropyl methylcellulose and glycerin, wherein the mass volume percentage of special low-ester pectin is 1.0%, and the mass volume percentage of hydroxypropyl methylcellulose is 0.5%. The mass volume percentage of glycerin is 1.0%.

[0089] A method for preparing a film-spraying agent for traumatic wounds containing rhubarb superfine powder, comprising the following process steps:

[0090] (1) Wash the rhubarb medicinal material and dry it for later use. The rhubarb is initially pulverized and passed through a 100-mesh sieve to obtain rhubarb coarse powder. Take the dried rhubarb coarse powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com