High-resilience spandex slice

A high-resilience, spandex technology, applied in textiles and papermaking, single-component synthetic polymer rayon, fiber chemical characteristics, etc., can solve the problems of reducing the quality of clothes, increasing costs, heat resistance is not as good as dry-spun spandex, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

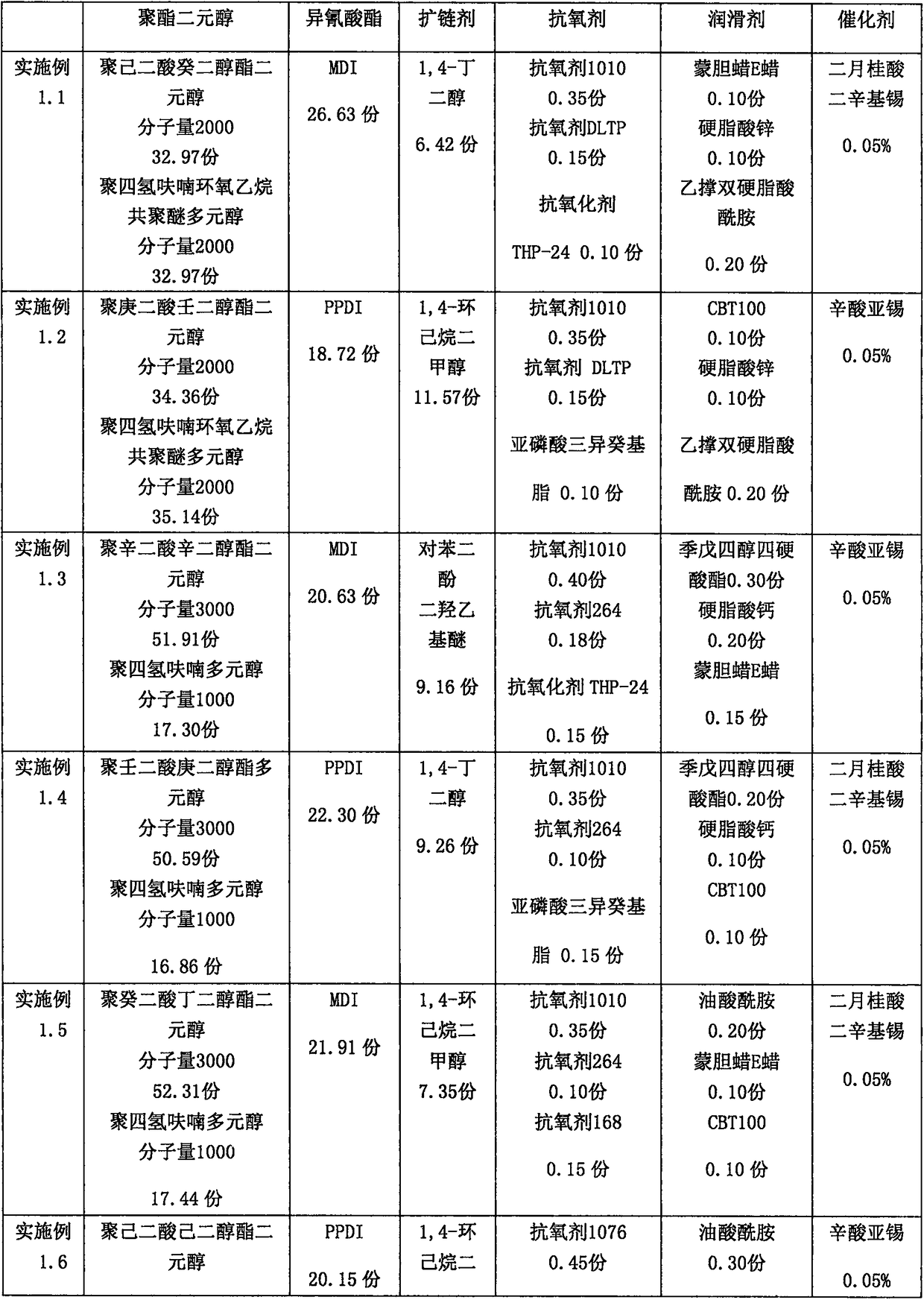

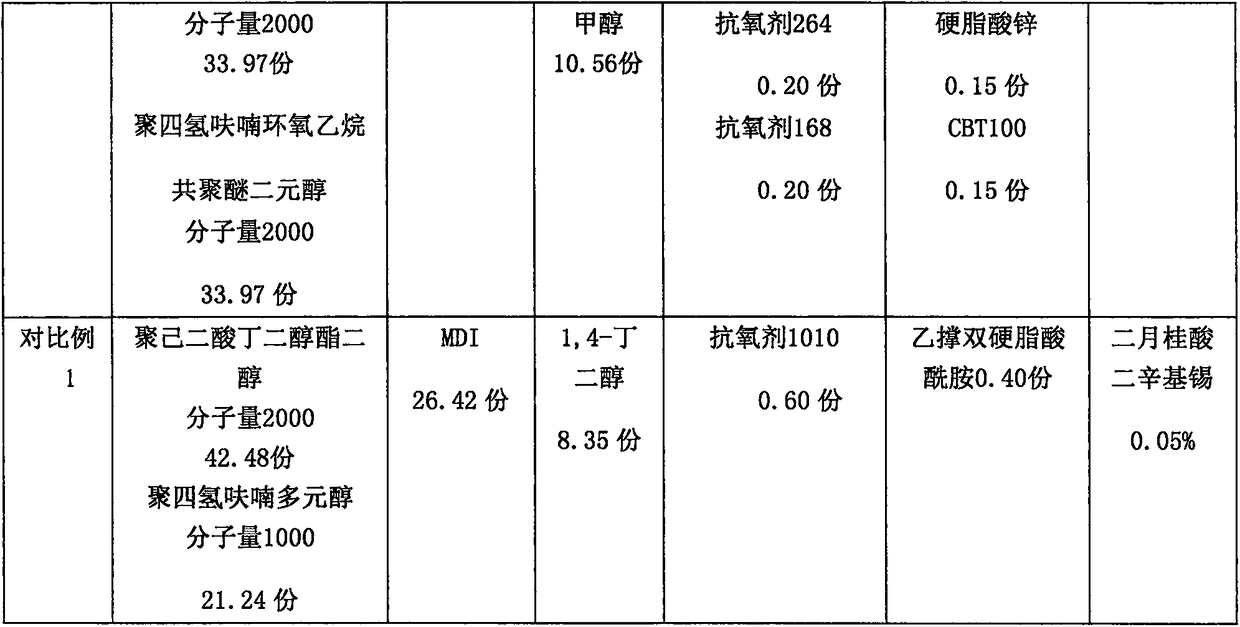

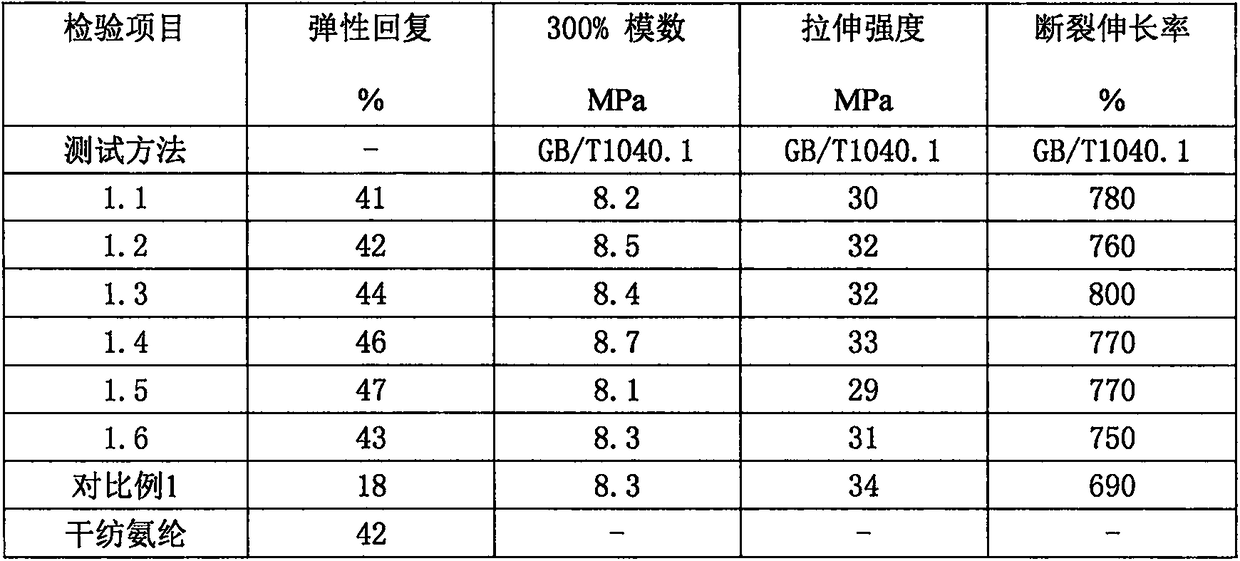

[0027] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0028] A kind of high-resilience spandex slice raw material formula of the present embodiment consists of:

[0029] 20-60 parts of aliphatic linear polyester diols with a molecular weight of 2000-3000 and repeating units containing more than 11 carbon atoms;

[0030] 15-45 parts of polyether polyols with a molecular weight of 1000-2000;

[0031] 20-40 parts of diisocyanate; 5-15 parts of chain extender, the chain extender is a diol with a molecular weight of 80-400;

[0032] 0.1-1.0 parts of antioxidant, said antioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com