Air-separation pre-cooling system

A chilled water system and pre-cooling technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as crystal blockage of calcium and magnesium ions, to solve crystal blockage, reduce load and The effect of energy consumption and huge economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

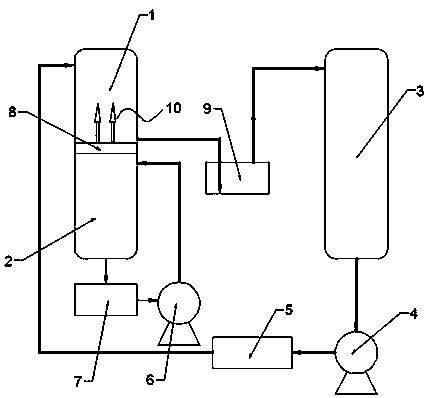

[0015] Such as figure 1 As shown, an air separation pre-cooling system, an air cooling tower 10, a chilled water system and a circulating water system, the air cooling tower 10 is provided with a distributor and a gas-water separation device 8 in the middle to separate the air cooling tower into the upper section 1 of the air cooling tower and the air cooling tower In the lower section 2, the chilled water system is used for heat exchange in the upper section 1 of the air cooling tower, and the circulating water system is used for heat exchange in the lower section 2 of the air cooling tower, wherein the distributor and the gas-water separation device are integrated.

[0016] Wherein, the chilled water system includes the upper section 1 of the air cooling tower, the refrigeration pump 4, the refrigeration unit 5, the liquid seal tank 9, and the water cooling tower 3. The outlet of the water cooling tower 3 is connected to the inlet of the refrigerating pump 4, and the outlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com