Copper smelting typical waste slag coordinated curing/stabilizing treatment method

A technology for stabilization treatment and copper smelting, applied in the removal of solid waste, etc., can solve the problems of low content of valuable metals and poor economic benefits of recovering valuable metals, and achieve the effects of improving overall strength, inhibiting expansion and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

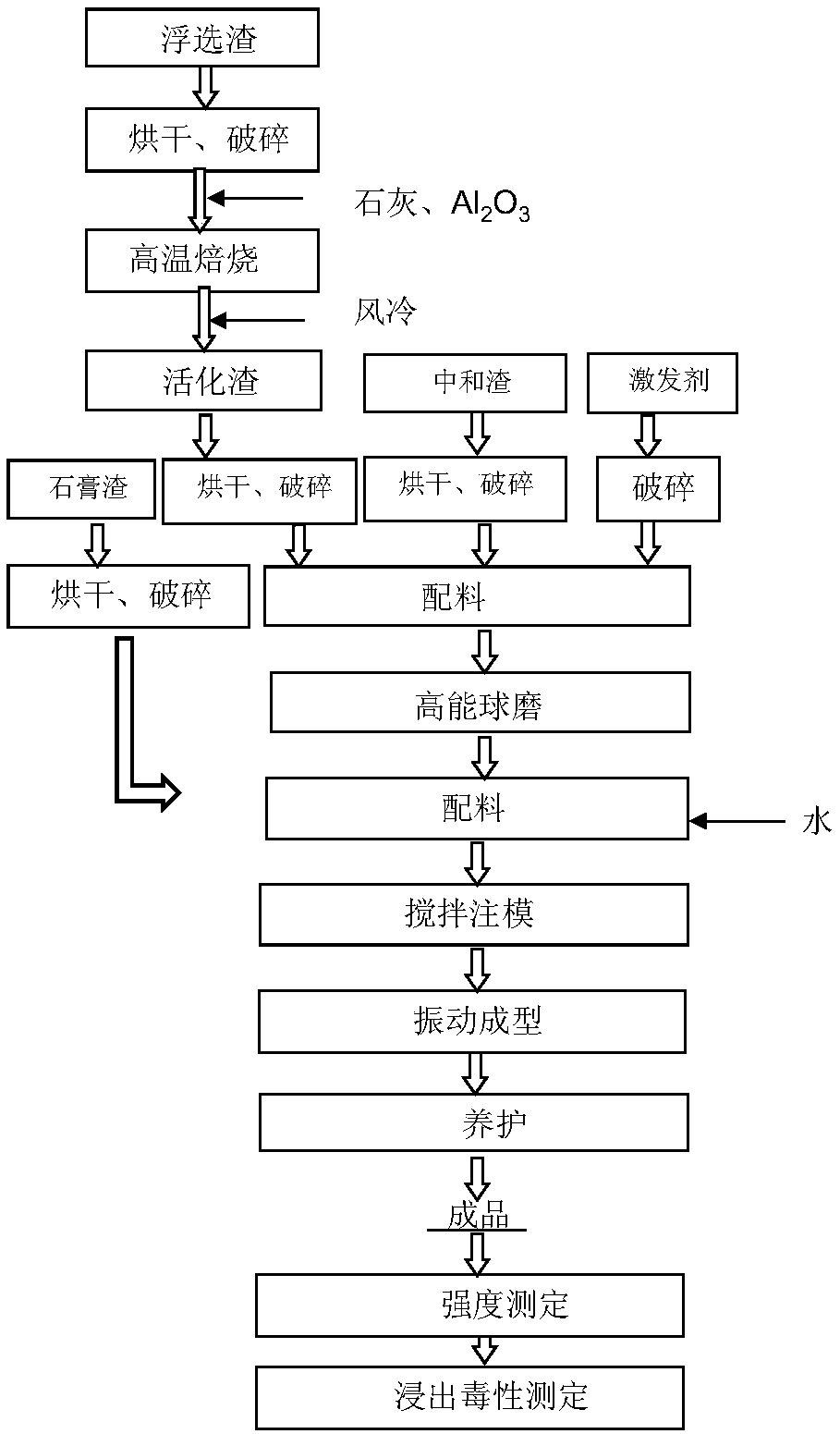

[0032] Embodiment 1: The typical copper smelting waste slag synergistic solidification / stabilization treatment method of the present invention, the specific operation is as follows:

[0033] Dry the flotation slag and neutralization slag to constant weight, and crush until the particle size is 80-100 mesh, and set aside.

[0034] CaO (25%), Al 2 o 3 (10%) and flotation slag (65%) were uniformly mixed, kept in a furnace at 1350° for 35 minutes, and then the roasted slag was placed in air to cool to obtain modified flotation slag.

[0035] Mix the modified flotation slag (70%), the neutralization slag (10%) and the activator (20%), and then ball mill, the ball milling time is 150min, and the particle size is controlled at ≤ 80μm to obtain the modified flotation slag base gelling material. Then the gypsum slag was dried to a moisture content of 20% and crushed to 300 mesh. Then the modified flotation slag-based cementitious material (70%) is uniformly mixed with gypsum slag (...

Embodiment 2

[0039] Embodiment 2: The typical copper smelting waste slag synergistic solidification / stabilization treatment method of the present invention, the specific operation is as follows:

[0040] Dry the flotation slag and neutralization slag to constant weight, and crush until the particle size is 80-100 mesh, and set aside.

[0041] CaO (25%), Al 2 o 3 (10%) and flotation slag (65%) were uniformly mixed, kept in a furnace at 1350° for 35 minutes, and then the formed slag phase was placed in the air for air cooling to obtain modified flotation slag.

[0042] Mix the modified flotation slag (70%), the neutralization slag (10%) and the activator (20%), and then ball mill, the ball milling time is 150min, and the particle size is controlled at ≤ 80μm to obtain the modified flotation slag base gelling material. Then the gypsum slag was dried to a moisture content of 20% and crushed to 300 mesh. Evenly mix the modified flotation slag-based gelling material (60%) with gypsum slag (4...

Embodiment 3

[0046] Embodiment 3: The typical copper smelting waste slag synergistic solidification / stabilization treatment method of the present invention, the specific operation is as follows:

[0047] Dry the flotation slag and neutralization slag to constant weight, and crush until the particle size is 80-100 mesh, and set aside.

[0048] CaO (25%), Al 2 o 3 (10%) and flotation slag (65%) were uniformly mixed, kept in a furnace at 1350° for 35 minutes, and then the formed slag phase was placed in the air for air cooling to obtain modified flotation slag.

[0049] Mix the modified flotation slag (70%), the neutralization slag (10%) and the activator (20%), and then ball mill, the ball milling time is 150min, and the particle size is controlled at ≤ 80μm to obtain the modified flotation slag base gelling material. Then the gypsum slag was dried to a moisture content of 20% and crushed to 300 mesh. Evenly mix the modified flotation slag-based cementitious material (50%) with gypsum sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com