Straight-through type plastic inspection well chamber forming processing device and processing method thereof

A technology for plastic inspection wells and molding processing, applied in the field of plastic inspection wells processing, can solve the problems of long manufacturing cycle, high mold manufacturing cost, low processing efficiency, etc., to reduce mold design and manufacturing costs, high welding efficiency, and welding deformation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

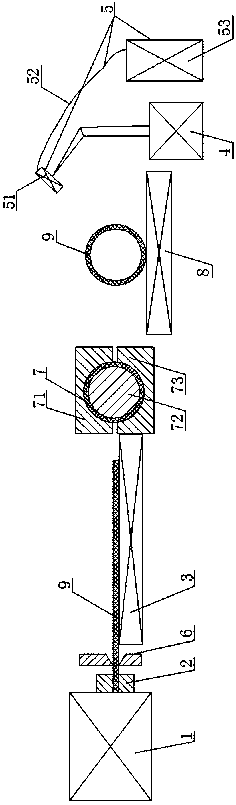

[0036] like figure 1 As shown, the straight-through plastic inspection well chamber molding processing device includes extrusion equipment 1, sheet material extrusion mold 2, sheet material conveyor 3, robot 4, laser output system 5, rolling mold 7 and automation for controlling the operation of the entire device Control system, the plate extrusion mold 2 is set at the exit of the extrusion equipment 1, based on the conveying direction of the plate, the extrusion equipment 1 is located behind the plate conveyor 3, and the extrusion equipment 1 and the plate conveyor 3 are set Plate cutter 6 is arranged, and the front end of plate conveyer 3 is provided with rolling die 7, and the front end of rolling die 7 is provided with circumferential body conveyer 8, and robot 4 is positioned at the place ahead of circumferential body conveyer 8.

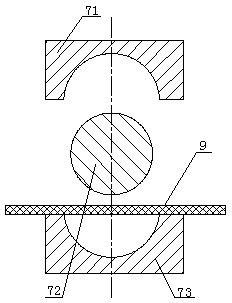

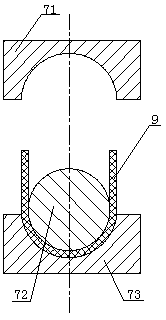

[0037] like Figure 2-5 As shown, the rolling mold 7 includes a concave upper semicircle template 71, a circular core 72 and a concave lower se...

Embodiment 2

[0049] The structure of the through-type plastic inspection well chamber forming and processing device in this embodiment is the same as that in Embodiment 1.

[0050] The processing method of the straight-through type plastic inspection well chamber molding processing device, the steps are:

[0051] (1) Preset the width of the plate 9 on the operation panel to be 1300 mm, and at the same time turn on the temperature controller 33, set the preset temperature to 180°C, and heat the conveyor belt 31;

[0052] (2) Put the raw materials into the extrusion equipment 1, extrude the sheet 9 from the sheet extrusion mold 2, the extruded sheet 9 passes through the sheet cutter 6, and the sheet cutter 6 cuts the sheet 9 into a preset width ;

[0053] (3) Apply black paint to the front and cut surfaces of the cut plate 9 to form a laser absorbing layer with a thickness of 0.8 μm;

[0054] (4) When the temperature of the conveyor belt 31 reaches the set temperature of 180°C, the plate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com