Corundum-silicon carbide crystal whisker composite ceramic material taking natural minerals as raw materials and preparation method thereof

A technology of silicon carbide whiskers and natural minerals, applied in the field of ceramic materials, can solve the problems of low product yield, high raw material cost, and high product cost, and achieve the effects of high mechanical strength, reduced product cost, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

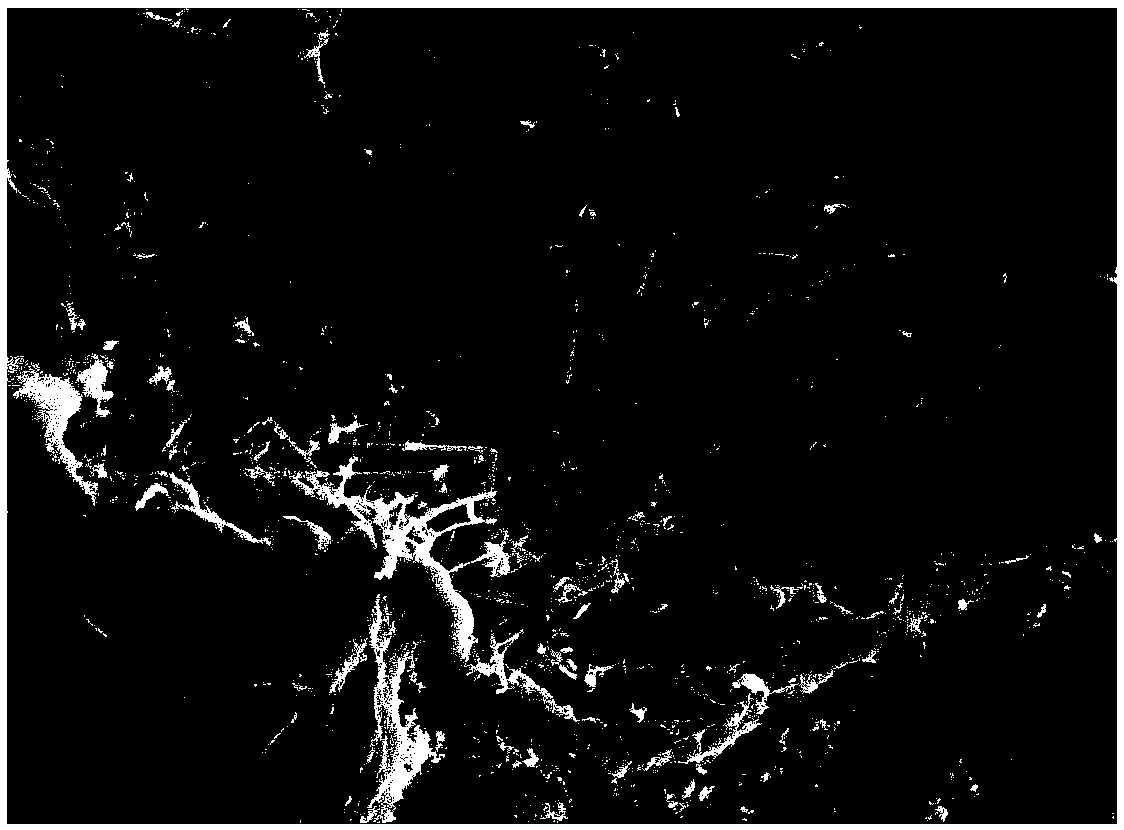

Image

Examples

Embodiment 1

[0022] 1. In this embodiment, a corundum-silicon carbide whisker composite ceramic material utilizing natural minerals as raw materials includes a base material and a binder. The base material is composed of kaolin (250 mesh) 65wt%, metal aluminum powder (180 mesh) 35wt%, the binding agent is a PVA solution with a concentration of 5wt%, and its consumption is 8wt% of the base material.

[0023] 2. In this embodiment, a corundum-silicon carbide whisker composite ceramic material using natural minerals as raw materials is as follows:

[0024] After mixing the above-mentioned base materials, add a binder and mix them evenly; after stirring and trapping the materials, select an appropriate pressure according to the size of the product for compression molding, and dry at a temperature of 110°C to obtain a green body (moisture content in the kiln <0.5%); then Embedding graphite powder and firing at 1450°C for 2 hours, the corundum-silicon carbide whisker composite ceramic material w...

Embodiment 2

[0026] 1. In this embodiment, a corundum-silicon carbide whisker composite ceramic material utilizing natural minerals as raw materials, including a base material and a binder, the base material is composed of kaolin (250 mesh) 40wt%, bauxite (180 mesh) 40wt%, metal aluminum powder (325 mesh) 20wt%, binding agent is the PVA solution of concentration 5wt%, and its consumption is 6wt% of base material.

[0027] 2. In this embodiment, a corundum-silicon carbide composite ceramic material using natural minerals as raw materials is as follows:

[0028] After mixing the above-mentioned base materials, add a binder and mix them evenly; after stirring and trapping the materials, select an appropriate pressure according to the size of the product for compression molding, and dry at a temperature of 110°C to obtain a green body (moisture content in the kiln <0.5%); then Buried carbon powder, fired at 1500°C for 2 hours, and the corundum-silicon carbide whisker composite ceramic material...

Embodiment 3

[0030] 1. In this embodiment, a corundum-silicon carbide whisker composite ceramic material utilizing natural minerals as raw materials includes a base material and a binder. The base material is composed of kaolin (250 mesh) 30wt%, andalusite (180 mesh) 40wt% %, metal aluminum powder (325 order) 30wt%, binding agent is the PVA solution of concentration 5wt%, and its consumption is 8wt% of base material.

[0031] 2. In this embodiment, a corundum-silicon carbide whisker composite ceramic material using natural minerals as raw materials is as follows:

[0032] After mixing the above-mentioned base materials, add a binder and mix them evenly; after stirring and trapping the materials, select an appropriate pressure according to the size of the product for compression molding, and dry at a temperature of 110°C to obtain a green body (moisture content in the kiln <0.5%); then Embedding graphite powder and firing at 1550°C for 2 hours, the corundum-silicon carbide whisker composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com