Combined polyether for high-temperature-resistant damp-heat rice steaming cabinet as well as preparation method and application thereof

A combination of polyether and rice steaming cabinet technology, applied in the field of polyurethane application, can solve the problems of poor resistance to high and low temperature cycle impact force, atmospheric ozone layer destruction, poor gas phase heat conduction, etc., to achieve high temperature and humidity resistance performance improvement, easy emulsification, excellent Effect of Flow and Filling Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

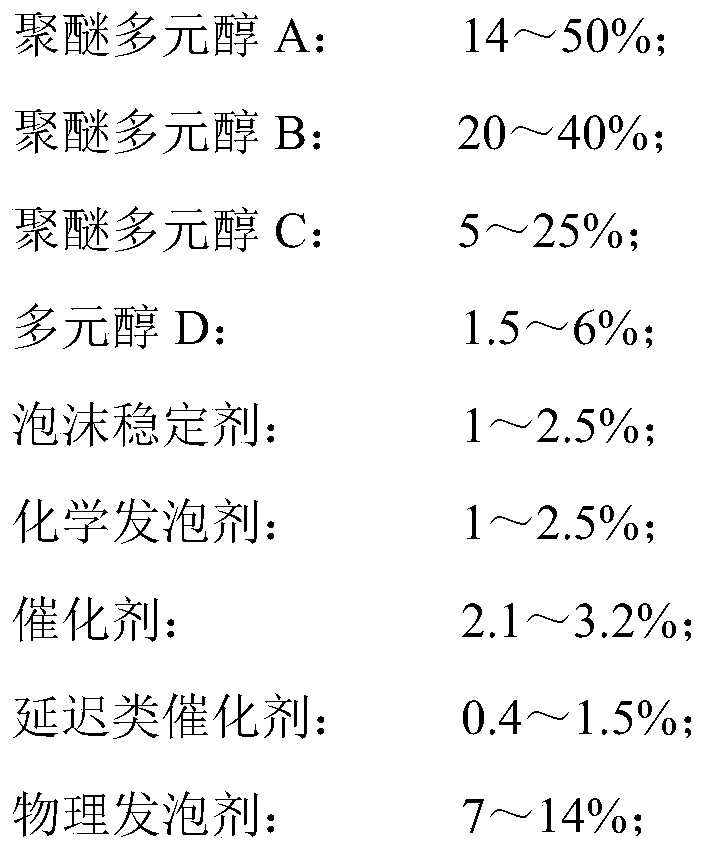

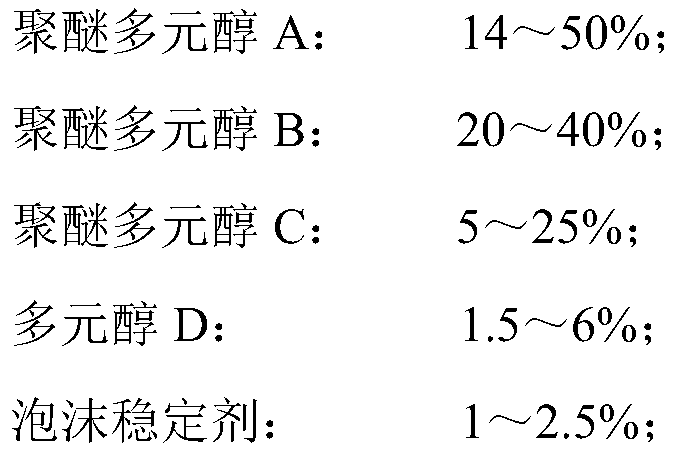

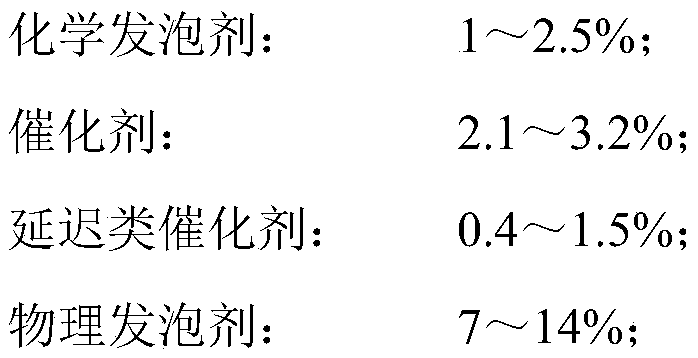

[0036] The preparation method of the combined polyether for the high temperature and heat resistant rice steamer is as follows:

[0037] A component material preparation:

[0038] Prepare component A materials in a 1-ton reaction vessel, and weigh them separately: polyether polyol A (Shandong Innovol New Material Co., Ltd. INOVOL R5118G): 60 parts; Company INOVOL R6207): 30 parts; polyether polyol C (Hebei Yadong 401P): 10 parts; polyol D (Cardolite NX-9001LV): 2 parts; silicone oil L-6863: 2 parts; chemical foaming agent h 2 O: 2.1 parts; Pentamethyldiethylenetriamine (PC5): 0.1 parts; N,N Dimethylcyclohexylamine (Air Chemical PC8): 1 part; N,N Dimethylbenzylamine (BDMA) : 1.5 parts, JXP508: 0.4 parts, JXP509: 0.6 parts; n-pentane: 16.5 parts.

[0039] Add the weighed polyether polyol A, polyether polyol B, polyether polyol C, polyol D, foam stabilizer, chemical foaming agent, catalyst, physical foaming agent and delayed catalyst to the reaction In the kettle, stir at roo...

Embodiment 2

[0047] The preparation method of the combined polyether for the high temperature and heat resistant rice steamer is as follows:

[0048] A component material preparation:

[0049] Prepare component A materials in a 1-ton reaction vessel, and weigh them separately: polyether polyol A (Shandong Yinuowei New Material Co., Ltd. INOVOL R5118G): 20 parts); polyether polyol B (Shandong Yinuowei New Material Co., Ltd. Co., Ltd. INOVOL R6350): 50 parts; polyether polyol C (Hebei Yadong 401P): 30 parts; polyol D (Cardolite GX-9104): 7 parts; silicone oil L-6863: 2 parts; chemical foaming Agent H 2 O: 2.6 parts; Pentamethyldiethylenetriamine (PC5): 0.5 parts; N,N Dimethylcyclohexylamine (Air Chemical PC8): 0.5 parts; N,N Dimethylbenzylamine (BDMA) : 1.5 parts, JXP508: 1.4 parts, JXP509: 1.5 parts; Isopentane: 17 parts.

[0050] Add the weighed polyether polyol A, polyether polyol B, polyether polyol C, polyol D, foam stabilizer, chemical foaming agent, catalyst, physical foaming agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com