High-fluidity high-strength high-toughness polypropylene composite material and preparation method thereof

A high-toughness polypropylene and composite material technology, applied in the field of polymer materials, can solve the problems of reduced fluidity and small amplitude, and achieve the effect of improving impact strength, excellent performance, significant lubricity and low melt viscosity characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

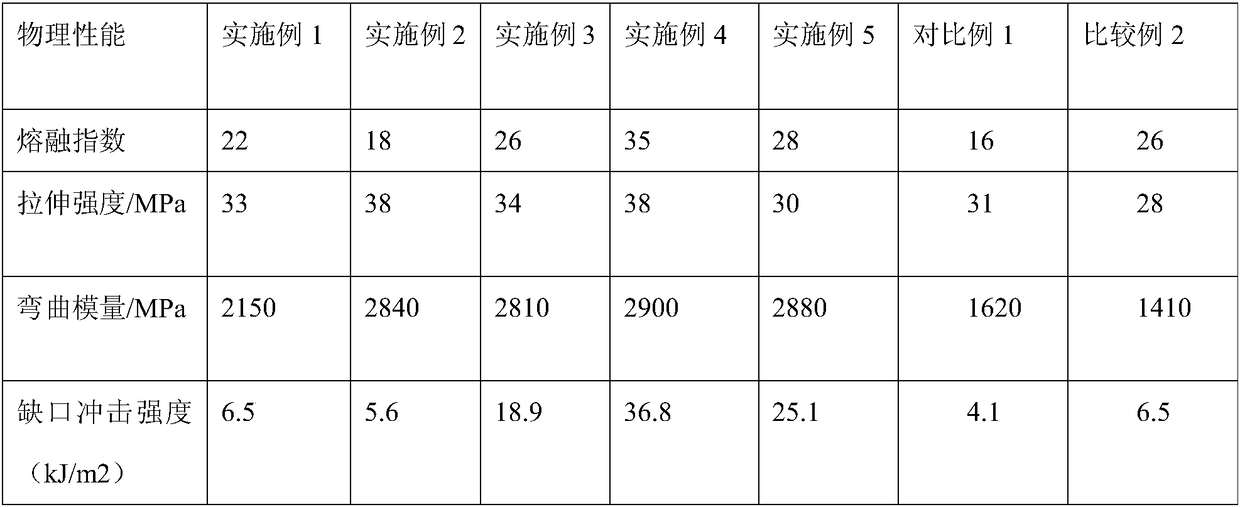

Examples

Embodiment 1

[0027] First weigh 96.6% of polypropylene, 1% of hyperbranched polymer, 1680.3% of antioxidant, and 0.1% of antioxidant DSTP into a high-speed mixer and mix for 3-5 minutes according to the following parts by weight. After being mixed evenly, the mixture is placed in the main feeding bin of the intermeshing co-rotating twin-screw extruder, and is added into the barrel of the extruder through the feeding screw, and 2% organically modified montmorillonite is weighed from The feeding port of the melting section is added to the extruder. The screw diameter of the extruder is 35mm, the length-to-diameter ratio L / D is 40, and the temperature of each zone of the main barrel from the feeding port to the exit of the machine head is set as: 190°C, 200°C , 200°C, 200°C, 200°C, 210°C, 210°C, the speed of the main machine is 250 rpm, and the polypropylene composite material is obtained through melt extrusion, cooling, granulation, and drying.

[0028] Product performance test:

[0029] Me...

Embodiment 2

[0031] First weigh 94.6% of polypropylene, 3% of hyperbranched polymer, 0.3% of antioxidant 168, and 0.1% of antioxidant DSTP in the following parts by weight and put them into a high-speed mixer and mix for 3-5 minutes. After being mixed evenly, the mixture is placed in the main feeding bin of the intermeshing co-rotating twin-screw extruder, and is added into the barrel of the extruder through the feeding screw, and 2% organically modified montmorillonite is weighed from The feeding port of the melting section is added to the extruder. The screw diameter of the extruder is 35mm, the length-to-diameter ratio L / D is 40, and the temperature of each zone of the main barrel from the feeding port to the exit of the machine head is set as: 190°C, 200°C , 200°C, 200°C, 200°C, 210°C, 210°C, the speed of the main machine is 250 rpm, and the polypropylene composite material is obtained through melt extrusion, cooling, granulation, and drying.

[0032] Product performance test:

[0033...

Embodiment 3

[0035] First weigh 89.6.% of polypropylene, 5% of hyperbranched polymer, 0.3% of antioxidant 168, and 0.1% of antioxidant DSTP in the following parts by weight and put them into a high-speed mixer and mix for 3-5 minutes. After being mixed evenly, the mixture is placed in the main feeding bin of the intermeshed co-rotating twin-screw extruder, and is added into the barrel of the extruder through the feeding screw, and 5% organically modified montmorillonite is weighed from The feeding port of the melting section is added to the extruder. The screw diameter of the extruder is 35mm, the length-to-diameter ratio L / D is 40, and the temperature of each zone of the main barrel from the feeding port to the exit of the machine head is set as: 190°C, 200°C , 200°C, 200°C, 200°C, 210°C, 210°C, the speed of the main machine is 250 rpm, and the polypropylene composite material is obtained through melt extrusion, cooling, granulation, and drying.

[0036] Product performance test:

[0037...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com